Fluidized Bed Air Current Pulverizing Machine

| US$6,000.00-8,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LQF

Material Processed

Plastic Flakes

Plastic Type

PP

Screw

Single-Screw

Automation

Automation

Computerized

Computerized

Certification

ISO9001:2008, CE

Raw Materials

Stainless Steel, Mild Steel;

Surface Treatment

Paint for Ms; Polish/Sandblasting for Ss

Power Supply

for Different Power Supply Application

Ex-Proof

Available

Customized Features

e.g. Light Glass, Special Dimension etc.

Special Treatment

Wear Resistant and Anti-Corrosion Available

Object

Plastic

Drive

Electric

Crushing Degree

Ultra-Fine Mill

Crushing Style

Impact

Principle

Fixed Culling

Cutter Material

Hard Alloy

Finished Surface

Outer Surface Process

Compressive Strength (for Crushing)

100-250MPa

Transport Package

Wooden Case

Specification

LQF-100

Trademark

SENFAN

Origin

China

HS Code

8474209000

Production Capacity

500/Year

Product Description

Fluidized bed air current pulverizing machineWorking Princible

After the materials enter the crushing chamber, they are fluidized under the action of the centripetal countercurrent jet field formed by the high-speed compressed jet flow. The accelerated materials converge at the intersection of multiple nozzles, generating violent impact, collision, and friction for crushing. The crushed fine powder moves along with the airflow to the upper part of the classification chamber. Due to the high-speed rotation of the classification wheel, the coarse powder returns to the crushing chamber for further crushing under the action of centrifugal force. The fine powder that meets the fineness requirements is discharged from the exhaust port and enters the cyclone separator and dust collector for collection. The dusty gas undergoes gas-solid separation in the dust collector, and the gas is discharged by the induced draft fan.

Performance & Characteristics

Low energy consumption. Compared with the traditional fluidized bed jet mill, it can save energy by 30%. Since the materials in the crushing chamber mainly collide with each other and rarely collide with the inner cavity of the crushing main machine, there is little pollution to the materials, and high-purity materials can be produced. Built-in self-diverting micro-powder classifier, with concentrated particle size distribution and no oversized particles in the finished product. Low-temperature crushing without medium, especially suitable for the crushing of materials with low melting points, heat sensitivity, sugar content, and volatility. For flammable and explosive materials, inert gas can be used as the medium to achieve fully enclosed crushing. The inert gas is recycled with low loss. It has automatic control capability and is easy to operate. Scope of Application

It is widely used in industries such as chemical engineering, mining, abrasive materials, refractory materials, battery materials, metallurgy, building materials, pharmaceuticals, ceramics, food, pesticides, feed, new materials, environmental protection, etc., and for the ultra-fine crushing, dispersion, and particle shaping of various dry powder materials.

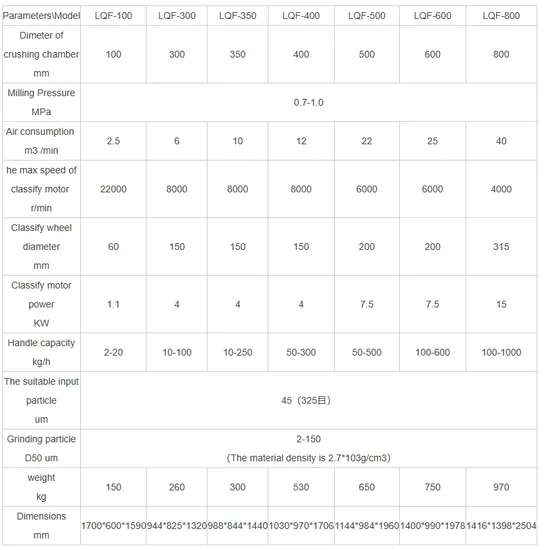

Product Parameters

Detailed Photos

Our Factory

Production Line

>> OEM Car Electronic Riha Plastic Injection Molding Mold Mould Products Customized Gear

>> IPS LCD Display Module 15.6 Inch 1920X1080 with Touch Screen Panel Optional TFT LCD Display

>> CE China Factory Small Hydraulic Metal Bending Folding Machine 50 Ton 1600 for Sale

>> China Rock Stone Jaw Crusher for Aggregate Production Line (C1210)

>> New TPR&ABS Fishing Knife Outdoor Camping Light Fish Fillet Knife with Black Coat and Scabbard Safety Fish Knife

>> Efficient Ring Die for Sheep Feed Pelletizing Machine

>> Drop Weight Impact Deflectometer ASTM

>> Good Service Injection Mould Negotiable Riha Offer Products Plastic Mold Gear Dampers

>> Detachable Long Bishop Sleeves Lace Custom Made Mermaid Wedding Gown

>> Hot Sale Camouflage or Solid Color Ice Towel Portable Magic Water Absorbent Instant Cooling Ice Towel for Sports

>> Hot Sale Suspension Leaf Spring Truck Trailer Leaf Spring Rear Leaf Spring for Semi Trailer Part and Auto Spare Parts

>> Thin Cover 12L Stainless Steel Trash Bin with Inside Plastic Bucket

>> WEIKA upvc sliding window handle zinc alloy windows lock with key gor sliding doors a glass panel window

>> Customzied Diamond Saw Blade Different Size

>> Yk-260my High Precision Fixed Head Inclined Bed CNC Milling Combination Machine Tool

>> Clear 100ml 250ml 500ml Plastic Bottle for Shampoo

>> New technology Manufacturers Electrochromic Windows Opaque Glass Cost Electric Shade smart Glass

>> SJ-BL2117 One Piece Swimsuit Women′s Sexy Sports Long Sleeve Printed Surf Swimsuit

>> Vmc850 CNC Milling Machine Vertical Machining Center with Qulified Manufacturer

>> Yeada Saferich at Mt Ht Car Tyres 31*10.5r15 265/60r18 265/65r17 33*12.5r18

>> Ruihang China Manufacturer Custom Plastic Mixer Blender Machine Raw Material Mixer

>> Top Technology Professional Automatic Servo Clamping Special Plastic Bottle Cap Handle Injection Molding Machine for 55mm Water Bottle

>> Modern Outdoor Decorative Stunning Metal Lotus Flower Statue Stainless Steel Water Fountain Sculpture

>> Sewing Accessories Silver/Gold Metallic Tape

>> Wholesale Cosmetic Grade Collagen Hydrolyzed Fish Collagen Powder

>> 30cm Tiffany Table Lamp Aolly Base Bedroom Bedside Lighting (WH-TTB-49)

>> Luxury Stainless Steel Rose Golden Mirror Round Shape Dining Table

>> W11S-25X2000 Hydraulic upper roller universal plate bending rolling machine

>> SRL-W300/1000 Plastic PVC CPVC UPVC Powder High Speed Horizontal Heat/Cool Mixing Equipment Factory Good Price

>> Automatid filling weighing packing machines for fresh lettuce salad bag