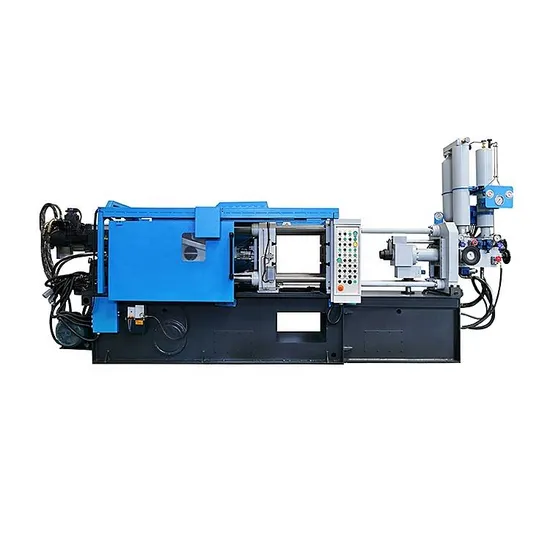

Horizontal Molding Machine Presse Injection Plastique

| Negotiable | 1 Set (MOQ) |

Basic Info.

Model NO.

SZ-950A, SZ-950A

Type

Injection Blow Molding

Structure

Horizontal

Plastic Type

Thermoplastic

Plasticizing Way

Plunger Type

Clamping Way

Mechanical

Automation

Automatic

Computerized

Computerized

Certification

CE

Screw Speed (Rpm)

1 - 15 Rpm

Clamping Force (Kn)

950 Kn

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Warranty of Core Components

1 Year

Name

Plastic Injection Moulding

Key Selling Points

Competitive Price

Country of Origin

China Jiangsu

Defects Liability Period

1 Year

Style

Horizontal

Brand

Smac

Machinery Test Report

Provided

Condition

New

Machine Type

Electric

Injection Weight (G)

103 G

Color

as Your Requirement

Transport Package

Packaging & Deliverypackaging

Specification

3.3 kg

Trademark

SMAC

Origin

Jiangsu, China

Production Capacity

30 Set/Sets Per Month

Product Description

Product Description

1.High position accuarcy:most suitable for machining parts such as dies,drilling or boring jigs and fixtures

2.wider range of application:drilling, boring, medium-load milling, scribing,scaling and measuring all are ok

3.various sizes of table:three standard sizes and much more amounts of size just as your requirement

The working principle of the injection molding machine is similar to that of the syringe for injection. It is the process of injecting the plasticized plastic in the melt state (i.e. viscous flow state) into the closed mold cavity with the help of the push force of the screw (or plunger), and obtaining the product after curing and shaping.

Injection molding is a cycle process, each cycle mainly includes: quantitative feeding - melting and plasticizing - pressure injection - mold filling and cooling - mold opening and parts removal. Take out the plastic parts and then close the mold for the next cycle.

| model | units | HL-1000A | HL-1320A | HL-1400A | HL-1650A | HL-1800A | HL -2050A |

| SCREW Diameter | mm | 36.38 | 38.4 | 38.4 | 42.45 | 45.48 | 45.48 |

| injection rate | g/'s | 90.95 | 95.1 | 95.1 | 135.155 | 142.16 | 140.159 |

| shot weight | g | 128/162 | 188205 | 230252 | 286/326 | 335/375 | 415/472 |

| clamp tonnage | KN | 1000 | 1320 | 1400 | 1650 | 1800 | 2050 |

| mould thickness | mm | 150-420 | 150-420 | 150-420 | 170-440 | 180-470 | 190-470 |

| space between tie-bars | mm | 385*350 | 410*375. | 428*386 | 455*425 | 480*460 | 490*464 |

| ejector stroke | mm | 125 | 135 | 140 | 155 | 155 | 155 |

| ejector tonnage | KN | 50 | 50 | 50 | 70 | 70 | 70 |

| hole diameter | mm | 100 | 100 | 100 | 125 | 125 | 125 |

| total weight | t | 3.4 | 3.9 | 4.2 | 5 | 5.5 | 6 |

Company Profile

SJR Machinery Co., Ltd. , was founded in 1984, which is the main partner member of China Jiangsu International Economic-Technical Cooperation Corporation. Our company specializes in the manufacture and import/export of brand new industrial machinery and tools. We are capable of producing more than 80 types of machines.Sincerely welcoming you to contact us for more information, we look forward to becoming your supplier in the near future.

Order Evaluation

Exhibition

Customer Photos

Certifications

FAQ

1. How can I choose the most suitable machines ? A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2. What is your payment terms ?

A: 30% down-payment after contract ,and 70% payment before shipment, Meanwhite it can be discussed according to your situation.

3: Where is our factory located? How can I visit there?

A : Our factory is located in No. 52 Linyin Road, Economic and Technological Development Zone, Nantong City, Jiangsu Province ,226001 China. You are warmly welcomed to visit us.

4. What is your delivery time ?

The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

5. Can you send the service engineer to our company ?

We have engineers stationed in Canada, Egypt, and Algeria. The after-sales service system is very perfect.

Horizontal Molding Machine Presse Injection Plastique

>> Diaper Machine

>> Kgs-Wm Programmable High Percision 3 Axis Auto Feed Servo Surface Grinder Machine

>> High Speed Paper Straw Making Machine

>> Outdoor Garden Aluminum Decking Flooring Waterproof Customized Modern Metal Deck

>> USB to DC Charging Cable Fan Cable DC USB Cable

>> 15kHz 2600W Ultrasonic Generator System for Plastic Welder Automated Assembly Line

>> XCMG Official Gtjz1012 Used Lifting Equipment 12m Electric Scissor Aerial Workl Platform

>> Extra Large Custom Non Woven Reusable Grocery Tote Bags

>> Hot sale Blend phosphate K7 use in meat keep water

>> anti-slip expanded metal walkway mesh grating platform

>> Small Thin Metal Plate Small Metal Parts Making Working Area 600*900mm High Precision CNC Fiber Laser Cutting Machine

>> Classic Blue Vintage Wash Women′s Sweater for Casual Style

>> Lump Crushers Plastic Lumps Breaker Machine Stainless Valve with Lump Breaker

>> Efficient Moisture Absorber 35oz Air Dryer Small Home Dehumidifier

>> OEM Optimum Nutrition Protein Powder Organic Mass Gainer Instant Drink Weight Gainer

>> Good-Performance 25 HP Single Row Corn Harvester

>> China Low Cost CO2 CNC Laser Engraving Machine for MDF

>> Automatic Self-Cleaning Liquor Disc Separator Suitable for Continuous Operation with 5000L-15000L Capacity

>> Easy To Operation Bamboo Toothpick Packing Machine

>> contemporary oval glass cheap wrought iron double entry doors

>> Customized 90 Degree Metal Shelf L Corner Brackets Angle Corner Bracket for Furniture

>> cheap Big glass panel sliding glass windows

>> Children′s Thinking Training Memory Chess Intelligence Wooden Toy

>> Cupboard Design Foshan Laminated MDF Gray Glossy Modern Cheap Modular Pull Down Small PVC L Shape White Shaker Kabinet Custom Italian Smart Kitchen Cabinet

>> UICE Outdoor sports waterproof bag PVC rafting swimming bag bucket ocean pack beach water bag

>> Shower Douche Accessories ABS Shattaf Bidet Spray and Hose

>> Factory Price Truck Sleeper Sling Strap Car Safety Seat Belt

>> Timing Kit for BMW N47 Timing Chain Kit OEM 11318510014 11317797899 TK2210-29

>> Plastic Shelf for Storage Mold Maker Chinese Factory Vagetable Shelf Injection Mold Plasric Mould

>> Excavator Customized Multifunctional Loading Excavator Construction