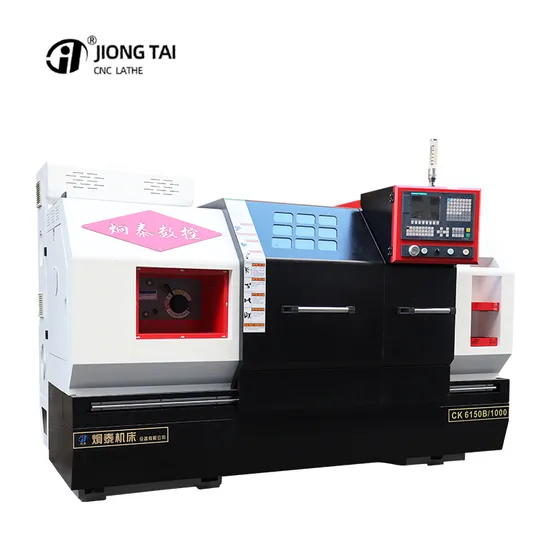

High Quality Flat Bed CNC Lathe Machine Ck6150b-1000 Horizontal CNC Lathe Machine

| US$8,000.00-15,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

CK6150B-1000

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Point to Point Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

Economical CNC Machine Tools

Condition

New

Tool Post Stations

4

Net Weight

2800kg

Automatic Grade

Automatic

Precision

High Precision

Transport Package

Seaworthy Packing

Specification

3000*1700*2000mm

Trademark

JT

Origin

China

HS Code

8458110000

Production Capacity

1500sets

Product Description

Product Parameters

Cnc Turning Machine Cnc 2 Axis CNC Turning Center CK6150B-1000

Features

1. Integral casting for bed and foot.

2. High rigidity, high precision, high speed independent spindle, through hole is Ф82mm.

3. Motor direct drive with variable speed .

4. Optimized structure, good accuracy and super stability.

| ITEM | UNIT | CK6150B-1000 | |

| General Rules | CNC system | GSK | |

| physical dimention | mm | 3000*1700*2000 | |

| The total weight of machine tool | kg | 2800 | |

| Scope of work | Max. workpiece rotation diameter of bed body | mm | 500 |

| Max.machining length | mm | 290 | |

| The X axis | mm | 295 | |

| Max. Z-axis stroke | mm | 500,1000,1500,2000 | |

| Bed | Width of bed rail | mm | 405, pallet pasting, integral bed foot |

| Max. apex distance | mm | 500,1000,100,2000 | |

| Spindle | Spindle head type | A2-8 | |

| Taper of spindle inner hole | Metric No. 90 (1:20) | ||

| Main shaft aperture | mm | 82 | |

| Spindle speed | m | Three speed variable frequency, stepless speed change in gear, 45-260140-800280-1600 | |

| Spindle motor powwer | rpm | Ordinary motor 7.5/optional 11 | |

| Manual three -jaw collet dimensions | Manual three jaw chuck 250 | ||

| Servo shaft | X/Z ball screw | 2505/4010 | |

| X /Z axis motor power | nm | 6/10 | |

| Working accuracy | Fast feed speed | m/min | 6;8 |

| Positioning accuracy | mm | X axis (transverse)≤0.01 Z axis (longitudinal)≤ 0.015 | |

| Repeated positioning accuracy | mm | X axis (transverse)≤ 0.01 Z axis (longitudinal) ≤ 0.01 | |

| Roundness | mm | < 0.007 | |

| Consistency in diameter | mm | ≤ 0.03/Length 300 | |

| Flatness | mm | ≤ 0.02/Diameter 300 | |

| Surface roughness(steel parts) | um | <Ra1.6 | |

| Tailstock | Diameter of tailstock sleeve | mm | 75 |

| Tailstock sleeve stroke | mm | 150 | |

| Taper hole of tailstock center | MT5# | ||

>> Longyu Steel Processing Services China Wholesaler Metal Laser Cutting Service

>> Honto Hengtuo Ht-1000mm 3 Layer Air Bubble Film Making Machine

>> Factory Made Good Quality Farming Equipment Battery Laying Hens Chicken Poultry Cage

>> DNA/RNA Nucleic Acid Extractor Automatic Nuzene96

>> Hot Sale 1325/1530/2030/2040 Woodworking CNC Router Machine 1325 Wood CNC Router

>> Energy saving laboratory diesel engine ball mill machine prices for gold copper ore iron ore

>> WiFi6 Standard 5g Wireless Router Support Poe, 2*2 MIMO Technology, with 4 Gigabit LAN Ports

>> Kowloon Tyre Rubber Powder Making Machine Price Pulverizer Machine for Rubber

>> High-Quality Customize The Logo Fingerprint Unlock Dual Card Smart Tablet PC

>> Custom Precious Plastic Resin Crate Mold Tool Storage Turnover Box Injection Mould

>> China Factory Price Morden Small Wheat Sorghum Rice Corn Grinding Mill Maize Flour Milling Machine

>> Pet/PE/PP Bottle Washing Line PE PP Crusher Granulator Washing and Recycling Recycling Line

>> Best Prices Breathing Hyperbaric Rebreather Nasal Oxygen Mask for Sale High Concentration Disposable Gas Pvc Ce OEM Service EOS

>> Bicycle Basket Front Basket Cheap Bicycle Accessories

>> API 6A Oilfield Wellhead Drilling Forged Blind Flange Alloy Steel 4130 75K

>> Versatile Excavator Grab for Steel and Copper Scrap Collection Needs

>> Windproof 16X8 12X14FT Metal Single Panel Sectional Overhead Garage Door for Home

>> Totally Automatic Egg Collecting System for Chicken Farm

>> Xiaomi Mijia Intelligent Air Fryer 1500W 3.5L Air Fryer for Baking Roasting Dehydrating Support Mijia App Control

>> Timing Chain Kit with OE 13028VJ200 130289E010 Apply to KA20DE 2.0L TK9380-2

>> aluminum auto radiator manufacturers for ISUZU truck 1-21410-674-1 8971771931 8973772380 8973543650 8-97371-010-0

>> Good Quality Three Point Mounted Disc Ridger for 20HP 60HP Tractor

>> Taijia concrete test hammer schmidt hammer concrete rebound hammer Hardness Tester

>> Diamond Saw Blade Welding Strength Testing Machine

>> Weldon Hot Sale Custom Stainless Steel Wall Metal Electric Junction Box

>> UGS62S 6 Positive 2 Reverse Double Side Automatic Garment Label Flexo Printing Machine, Cotton Webbing Flexographic Printer

>> Canvas and Leather Bicycle Water Bottle Cup Holder Bag Wine Carrier

>> High Quality Pure Pharmaceutical Grade Pullulan Powder

>> Complete and Desirable Liquid Nitrogen Producing Plant

>> Medical Orthopedic Surgical Broken Nail Screw Extractor Skid Screws Removal Instrument Set