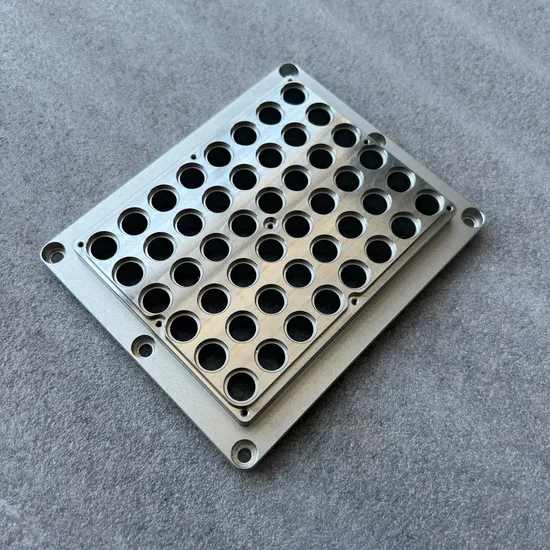

Custom Precision HRC/Anodizing/Electroplating/Turning/Milling/Grinding/EDM/Fabrication/CNC Machining Parts for Electronics/Machine/Automotive/Car/Engine Spare

| US$1.00-5.00 | 10 Pieces (MOQ) |

Basic Info.

Model NO.

ZR-AL103

Condition

New

Certification

ISO9001

Standard

DIN, ASTM, GOST, GB, JIS, ANSI, BS

Customized

Customized

Material

Aluminum

Application

Metal Processing Machinery Parts

Material Row No.

Al-6061 T6

Anodized

Raw Color

Tolerance

+-0.0005

Features

Precise, Small, Special

Quality Control

100% Inspection CMM Optional

Machining

CNC Manufacturing, CNC Processing

Processing

Wire EDM/Milling/Grinding/Punching/Laser Welding

CNC Machining Center

3/4/5 Axis

Application Aera

Medical/Electronic/Aerospace/Semiconductor/Auto

Optional Processing Methods

Stamping/Diecasting/Casting/Lathe/Heat Treatment

Optional Surface Treatment

Blackening, Polishining, Anodizing, Sandblasting

Classification

Shaft/Bearing/Housing/Fastener/Gear/Cap/Drive

Knurling

Cooper, Steel, Metal,Aluminum Alloy

HRC

Above 60

EDM

Wedm-Ls, Wedm-HS

Transport Package

Carton

Specification

customized

Trademark

ZR

Origin

Shandong, China

Production Capacity

1000 Piece/Pieces Per Month

Packaging & Delivery

Package Size

20.00cm * 20.00cm * 20.00cm

Package Gross Weight

2.000kg

Product Description

Product DescriptionWelcome to the world of Zhengrong precision machining.

With nearly 20 years of processing experience and are one of the oldest machining factories in China.

We specialize in the processing of precision, complex, special, small parts, and we have rich experience in CNC machining, lathing, milling,grinding, EDM, and wire cutting machining.

Especially in semiconductor testing equipment, medical equipment, automation equipment,electronic equipment, precision chemicals, aerospace, various machinery and other fields, it is widely used.

We enjoy a well-established reputation both domestically and internationally. And have established long-term friendly cooperative relationships with many customers in Japan, the United States, Europe, etc.

Detailed Photos

Main product

MORE PRODUCT INFORMAITON,

PLEASE CLICK HERE FOR OUR PRODUCT CLASSIFICATION.

Application Area

MORE APPLICAITONS,

PLEASE CLICK HERE FOR MORE INFORMATION.

Process

Our Strength

1. Small Batch & Single Piece Orders Welcome (MOQ=1 piece): We understand that your project needs may vary, and we're happy to accommodate single-piece orders or small batch runs.

2. Fast Lead Times: Get your parts quickly! Our lead times start at fast as 7 days, ensuring you receive your order efficiently.

3. Flexible Payment Options: We offer flexible payment terms with a 50% upfront deposit and the remaining balance due after successful quality inspection and your satisfaction.

4. Extended Warranty with 24-Hour Support: We stand behind our work. Our extended warranty provides peace of mind, and our dedicated team will offer solutions within 24 hours should any issues arise during the warranty period.

5. Uncompromising Quality Control: Every step of the production process undergoes rigorous inspection by our quality control department. Any parts not meeting our high standards are returned for rework, guaranteeing you receive top-quality products.

6. Documented Quality: We provide complete documentation for your parts, including raw material certificates, heat treatment reports, and detailed quality inspection reports.

7. Cost-Saving Expertise: With extensive experience, we can combine various processing techniques to optimize your project's costs while maintaining exceptional quality.

8. Secure and Professional Packaging: We employ professional packaging solutions tailored to the specific materials of your parts, ensuring they arrive safely and securely.

9. DDP trade terms : double customs clearance to door service, eliminating the customs clearance process and delivering the goods directly to you by express or air dispatch.

10. ISO Certificate

Company Profile

We the company of Qingdao Zhengrong Precision Machinary Co., Ltd. was established in February 2007, located in chengyang district, Qingdao city.

The company has strict quality management in accordance with ISO9000.

We specialize in the processing of customized metal, aluminum, brass, stainless steel, plastic and other parts made of different materials. Our company has over 40 machines, including lathes, milling machines, grinders, wire cutting machines, CNC machines, and other equipment. We also have a professional quality inspection department and various testing equipment to ensure that products are qualified before leaving the factory.

Processing Equipment

Inspection Instrutment

Packaging & Shipping

Packing process: Clean the workbench and prepare for packaging work.

If rust prevention treatment is necessary, it is necessary to take measures to prevent rusting. The parts coated with oil should be packaged with oil sealing paper. Roll up the buffer material. Standard for bundling transparent cling film

FAQ

Q1:What's kinds of information you need for quotation?

You can provide 2D/3D drawing or send your sample to our factory, then we can give your a quotation within 24 hours.

Q2: Can we sign NDA?

Sure. We never divulge customers' information to anyone else.

Q3: Do you provide sample?

Yes, we can provide you sample before mass produciton.

Q4: How can you ensure the quality?

We have profesional QC department to guarantee the quality.

>> Automatic Center Pivot Irrigation System

>> Steel Round Flat Bar and Carbon Steel Cold Drawn Steel Square Carbon Steel Round Bar 1215 12L14 4140 4135 8620 Sj235 C45 S45c C35 S35c

>> 5 LED Bulbs Air Turbine High Speed Handpiece Air Turbine 2hole 4hole

>> Double-Shaft Shredder Blade Plastic Film Household Waste Packing with Crusher Rotor Knife Claw Knife Crushing Knife

>> Tower Fabrication Machine FINCM CNC Transmission Tower Power Transmission Steel Shear Shearing Marking Punching Machine

>> Wind Power Hydraulic Pipe Flange for Foundation Ring

>> Hot Sale Fishing Net Machine with Single Knot Nylon/HDPE Braided Sports /Fishing Net

>> Auto Car Rear Bumper Step Pad For Toyota Tacoma 2012 - 2015 52162 - 04011

>> Ruipuhua Secondary Packaging System For Single Pouches Secondary Packaging Machine Flow Wrapper

>> Thermal Break Aluminum Casement Window Double Toughened Glass accesorios para ventanas de aluminio

>> 3.5 Inch LCD Screen Portable Flexible Bronchoscope/Nasopharyngoscope/Cystoscope

>> 31126315 Tractor Con Rod Bearing for Massey Ferguson 85035

>> Agricultural Industrial Implement Truck Wheel Rim Disc Plate Od587 mm

>> OEM 84364222/84364223 High quality front wheel liner FOR CHEVROLET EQUINOX 2017-2019

>> Ignition Coil for Holden Astra Ah Ts 1.8L Holden Barina Tigra Xc

>> 6011 Style Number Trendy 2025 New Style Casual Jeans for Women - Fashionable Denim Collection

>> 99% Purity Preparation of Phosphate Pigments Copper Pyrophosphate for Electroplating Additive CAS 10102-90-6

>> Adjustable Universal Car Racing Bucket Seats

>> 100% Polyester Anti UV Textile 600*300d PVC Fabric Wholesale

>> 1.6 mm Thickness Full Grain Natural Chrome Tanned Cow Genuine Leather from India

>> Advanced Modular Floating Excavator Platform Barge for Construction Applications

>> Diamond Multi Wire Saw for Granite Block Profiling

>> HDPE PP Plastic Bottle Barrel Jerry Can Making Extrusion Ball Making Blow Blowing Molding Machine

>> Glass Cat Eye Road Stud / Road Block / Reflective Material Round Top

>> Comfortable 100%Linen Women Strappy Long Dress with Metal Zipper

>> Excellent Performance Portable Barcode Scanner for Reading 1d&2D Code

>> New Design Home Dual Exercise Bike Td001p-1

>> Cow crazy horse Leather Wallet for men vintage 2022 style slim smart wholesale retail customised custom logo full grain

>> Outdoor Activities Team Game Electric Soft Bullet Blaster Pistol Fun Water Beads Shooting Gun Toys for Kids Boys and Girls

>> 26m Crawler Anti-Top Platform Self-Propelled High-Altitude Brick Press