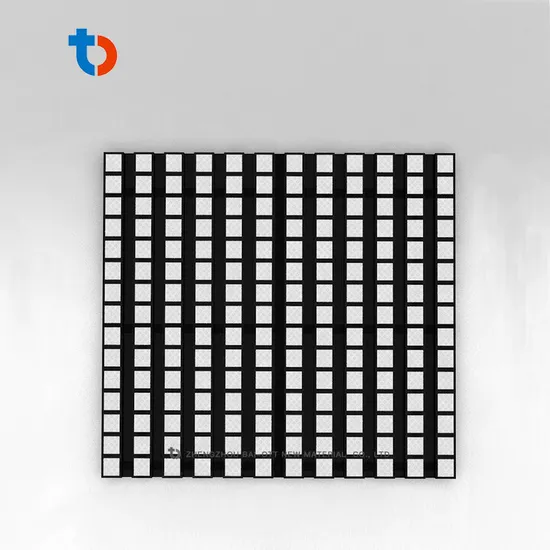

Ceramic Pulley Liner Tire Lagging Rubber Sheet

| US$200.00-500.00 | 1 Square Meter (MOQ) |

Basic Info.

Model NO.

3522110

Feature

Wear-resistant, Impact-resistant, Heat-resistant, Corrosion-resistant, Insulating, Cold-resistant, Increased Friction

Raw Materials

Natural Rubber, Ceramics

Medium

Pure Gum Rubber Sheet and Fabric

Performance

Insulation and Corrosion Resistant Rubber Sheet

Color

Black Rubber Sheet

Standard

DIN

Application

Construction Machinery, Cement Plant, Mining Machine, Thermal Power Plant, Coal Yard, Conveyor Pulley Lagging

Type

Wear Resistant Casting

Product Name

Pulley Lagging Rubber Sheet

Elongation

450%

Thickness

8/10/12/15/20mm or OEM

Hardness of Rubber

65 Shore a

Installation

Cold Bonding

Length

in Pieces or in 10m Rolls

Delivery

Good Delivery Time

Features

with Cn Bonding Layer

Certificate

ISO9001, ISO14001, ISO45001

Transport Package

Pallet

Specification

2000mm*10000mm or OEM

Trademark

BAI-OTT

Origin

China

HS Code

4008210000

Production Capacity

200, 000 Meters/Year

Product Description

TIPTOP Conveyor belt ceramic rubber drum lagging manufacturerBAI-OTT ceramic pulley lagging sheet provides the best grip for your head drum. The ceramic inserts in the lagging surface provide both high friction and high wear resistance-providing the best protection for your pulley and belt in the most demanding conditions. Ceramic pulley lagging is ideally suited for wet and muddy conditions where belt slippage can be a major problem.

The high co-efficient of friction of the ceramic tile inserts with the belt also allows for belt tension to be reduced. This also improves the service life of the belt, as well as that of the other belt components as they come under less stress.

Features:

1.Improve friction coefficient between drive pulley and conveyor belt

2.Minimizing of conveyor belt slip

3.Prevent material build-up

4.Protection against wear and corrosion.

5.To balance wear resistance and elasticity of the rubber, Bai-ott tested many formula to get the suitable one.

>> Oxygen and Nitrogen Storage Tank for Liquid Cryogenic Applications

>> AAC Brick Making Machine Production Line in India

>> Fast Delivery Small-Floating-Fish-Feed-Extruder-Machine + Floating Fish Food Feed Pellet Machine + Fish Feed Machine for Agricultural Use

>> FRP/GRP Mesh Grating for Safe and Reliable

>> Luxury Ins Fashion Promotional Pearl Necklace Stainless Steel Metal Bracelet Branded Designer Wholesale Ring Replica Online Store 1: 1 Jewelry Earrings Necklace

>> Custom 2022 Fashion Professional Classic Shirts with 100%polyester

>> a Type Layer Chicken Battery Cage in Poultry Farm Hot Sale in Nigeria Kenya Zambia Uganda Tanzania

>> New Design Alloy Wheels Rims

>> China Factory Reliable Manufacturer 30000 BTU 2.5Ton Split Klimaanlage R32

>> Custom High Quality Aluminum Waterproof Food Wrapping Film Candy Potato Chips Chocolate Sachet Bakery Packaging Mylar Bags

>> 4040lp Low Pressurereverse Osmosis Membrane Water Treatment Industry RO Plant

>> Horizontal Surface Grinding Machine China Grinder Manual Grinding

>> Performance Racing Race Clutch Hydraulic Throw Out Bearing For Multi-disc Racing Clutches

>> Multi Color High Speed Ball Candy bag High Speed Package Machine

>> Adjustable 5 Ropes SPring tube Exercise Resistance Bands Arm Strength Trainer for Muscle Training

>> Fish Farm Cage Culture Fishing Equipment Fish Farming Equipment

>> Sandwich insertion type Ultrasonic Water Meter sandwich insertion type digital flow meter water

>> High-Quality Riding Green Sand Top Dresser Tdrf15b Model

>> Exclusive Range of Full Grain Sustainable 22 sqft Vegetable Tanned Cow Genuine Leather for Sale

>> High Standard Horizontal Injection Moulding Machine for Garbage Bin

>> Music MP3 Player HiFi Sound Recorder with Logo Customize for Promotional Gift

>> Back Massage Stretcher Fitness Equipment Back Massage Wyz15191

>> Pneumatic 4 Inch Flanged Check Pipe Fittings Low Lead Water Brass Mini Ball Valve

>> Factory Wholesale Custom Shape Plain Accessories Engraving Logo Wooden Keyring Surfboard Blank Wood Keychain

>> New Design Kids Garden Playground Inflatable Jumping Castle for Sale

>> Yuemai Winter Keep Warm Men′s Plush Camouflage Ushanka Hat

>> High Strength and Toughness Nodular Cast Iron Roller From China for Rebar

>> Precision Plastic Injection Molding Equipment for Superior Output

>> Mixing blenders equipment industrial plastic powder formula weighing machine for extruder micro gravimetric doser mixer

>> In Stock Automatic Incense Packing Machine Candle Packaging machine