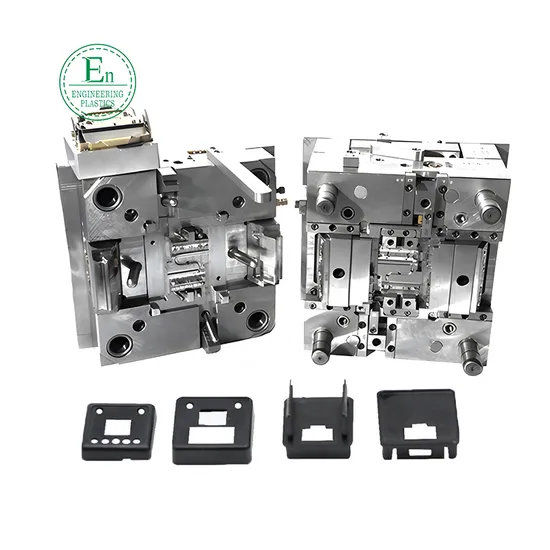

Ug Fixed Boxs China Auto-Parts-Products ODM Tools Plastic Moulding Custom Injection Mold

| US$3.00 | 10 Pieces (MOQ) |

Basic Info.

Model NO.

Aut Service Plastic Molding Parts

Surface Finish Process

Polishing

Mould Cavity

Single Cavity

Plastic Material

Plastic

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Certification

ISO

Standard

HASCO

Customized

Customized

After-sales Service

Custom

Color

Custom

Service

OEM\ODM

Drawing Format

2D/(Pdf/CAD)3D(Iges/Step)

Thickness

1-20mm

Transport Package

Boxs

Specification

custom

Trademark

gz-plastic

Origin

China

Production Capacity

5000PCS/Month

Packaging & Delivery

Package Size

40.00cm * 40.00cm * 50.00cm

Package Gross Weight

10.000kg

Product Description

Leading Global Injection Molding Supplier Assist global clients in professional custom injection molding service,CNC machining service and engineering material.We can provide you with one-stop solutions.Main Product: 1.Custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment(paint, print, water trans-print, welding, assemble) . 2.Engineering plastics products Processing: gear and rack,guide,pulley,guide rail,Sealing ring,rod,Tube,and many machined parts ect. Products Tolerance +/-0.01mm.

How to get a quotation: 1. Prepare a picture or 3D drawings; 2. You want the products material;

| Company Name | Guangdong Engineering plastics Industries(Group)Co,Ltd |

| Brand | Guangdong Engineering plastics |

| Main Product | Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc |

| Injection Machine (Double Color) | 88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T |

| Application | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc |

| Mould Base | LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc. |

| Mould Material | 718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc |

| Moud Precision | +/-0.01mm |

| Mould Life | 100K-1000K shots |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Manufacturing Equipments | Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc. |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Lead time | 15-30 working days for injection moulds,plastic products according to quantity |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Our Spirit | "Engineering Plastics" can be used instead of "Steel"! Science and technology will change the future! Guangdong Engineering Plastics Industries Company! |

| Other | 24 hours instant and comfortable customer service! |

| Shipping status notification during delivery! | |

| Regular notification of new styles & hot selling styles! |

The production process of injection mold refers to the process of melting plastic raw materials by heating, then injecting them into the mold, cooling and solidification, and finally obtaining the required molding products. Injection mold production process mainly includes the following steps:

1. Pretreatment of plastic raw materials: including drying, mixing, adding color and other processing to ensure the quality and stability of plastic raw materials.

2. Mold design and manufacturing: according to the shape, size, material and other requirements of the required molding products, design the corresponding mold and manufacture.

3. Injection molding: the pre-treated plastic raw materials are heated and melted, and then injected into the mold, and after cooling and solidification, the required molding product is finally obtained.

4. Finished product treatment: including slag removal, trimming, grinding, painting and other treatments to improve the quality and beauty of the finished product.

Certifications

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Application

Our Factory

Our Exhibition

Cooperative Case

>> High Performance 3D Printing Coated Sand Mold Parts for Manufacturing Industry

>> Christmas Family Server Tray Kitchen Mini Bamboo Cheese Board With Cheese Tools

>> Aqualand 27feet 8.3m 14pax Fiberglass Aluminum Rib Speed Rescue Patrol Aluminium Diving Rigid Inflatable Passenger Sport Diving Fishing Speed Motor Yacht Boat

>> Bf Remote Control Multifunctional Track Farm Machine Crawler Tractor Untryside Supervisor Machine

>> Zhongda Hengyuan 2% Haematococcus Pluvialis Extract Powder Astaxanthin

>> Flexible Automation and Efficient All-Electric Servo Bending Machine

>> Cordless Electric 21V Rechargeable Battery Circular Saw

>> powder coating aluminum triple track inside grill glass sliding window with mosquito net

>> Heavy-Duty Sleeveless Work Jumpsuit Designed for Maximum Durability

>> TEM82E Electormagnetic Flow Meter Digital Liquid Flowmeter Stainless Steel Flow Meter Inductive Meters

>> UPVC vertical sliding window with surface mounted Georgian Bars

>> Kitchen Soundproof Aluminum Sliding Window Frame Aluminum Vertical Sliding Windows

>> Double Spindle High Speed CNC Vertical Drilling Machine

>> Chnviken Nc 125t3200mm CT8 Controller System Hydraulic Press Brake for Metal Plate Bending Machine in Aircraft Manufacturing

>> High Quality Factory Sell High Quality NPK Fertilizer with 12-12-17 15-15-15 20-5-5 16-20-0 for Fruits

>> Amazon hot sale rich oxygen portable mini membrane oxygen concentrator

>> Wholesale Products Promotion Gifts Card Packaging Custom Design Decorative Auto Hanging Perfume Paper Car Air Freshener

>> Custom Heat Seal Print Package Aluminum Foil Laminated Plastic Zip Zipper Pouch food Bag

>> Hubei Yuli "SHARPNESS" WA White Corundum Abrasive Sanding Mesh Sheet 115x280mm for Ceramic Sanitary Wall Floor Sanding Grinding

>> AU-300C High Precision Digital Acid Concentration Meter, Acid Concentration Tester, Acid Concentration Test Equipment

>> Custom Logo Durable Multi-Pocket Waist Bag Outdoor Adventure Essentials Backpack Waist Bag Waterproof Waist Bag

>> Pet Bottle Label Peeling Machinery

>> Automatic Waste Tire Recycle Machine / Tyre Shredder / Rubber Tile Making Machine

>> Open Frame USB Interface LCD Display Wide Veiw Angle Touchable Screen

>> Sonic Toothbrush Electric for Adult Smart Rechargeable Electric Toothbrush Teeth Cleaning

>> Flame LED Light Wireless Outdoor Speaker Dual 5.5′′ Woofer Boombox Bluetooth Speaker Party Partybox

>> High-Quality Bucket Car Seats High-End Sports Racing Car Seats

>> Aluminum Emergency Eyes Shield Tactical Medical Metal Eyes Shield for First Aid Kit Ifak with Holes Disposable Ophthalmic as Hospital Equipment

>> Wholesale Plastic Rotary Shredder Crusher Blades

>> Supply Top Quality Fresh Yellow/Red Onions Wholesale Onion