Pyrolysis Machine 500kg Waste Plastic to Diesel Machine Small Reactor for Plastic Pyrolysis

Basic Info.

Model NO.

BN-PRF

Structure

Horizontal

Transport Package

Full Container

Specification

600.00cm * 230.00cm * 200.00cm

Trademark

BNTET

Origin

China

HS Code

8419409090

Product Description

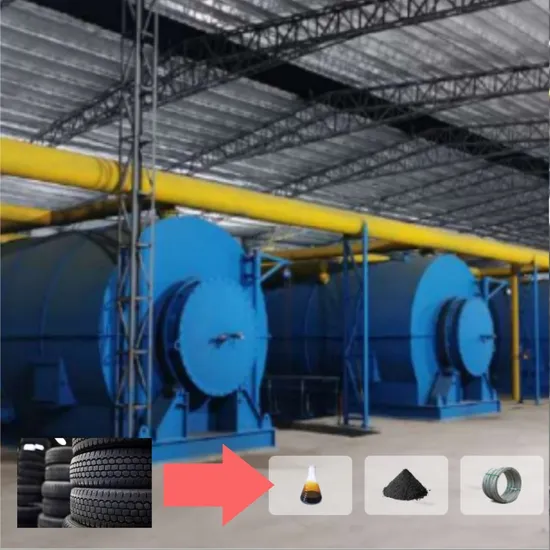

Product Information -What is Plastic Pyrolysis Plant? Waste plastic pyrolysis plants are facilities that convert many types of waste plastics into useful substances without releasing harmful by-products. This process, called pyrolysis, uses controlled heat to break down the large molecules in the plastic into smaller components that can be used for a variety of purposes. The main source of fuel for the pyrolysis plant is plastic waste,which can be converted into oil. -Raw Materials: Waste Plastic Types PE, PP, PS, ABS - Recommended to produce pyrolysis oil* Recommended for their high oil yield during decomposition. PVC - Not suitable for pyrolysis

* Contains chlorine, and during decomposition, it releases hydrogen chloride, which can corrode pipes and equipment.

* Combustion of decomposed PVC can release carcinogenic dioxins. PET - Not suitable for pyrolysis

* Does not yield oil during decomposition.

* Releases oxygen during the decomposition process, posing a safety hazard.

Final Product Applications 1.Fuel Oil (40%-45%): Known as fuel oil, pyrolysis oil, heating oil, furnace oil. Used as industrial fuel for cement plant, steel

plant, metallurgical plant, glass plant, power plant etc.

2.Carbon Black (30%):Used as raw materials for rubber and plastic industries after further processing. Or used as heating fuel.

3.Flammable Gas or Steel wire(25%-30%): Known as combustible gas or non-condensable gas. Routed to gas burners of heating system as fuel supply. Product Description

| Model | BN-PR-3 | BN-PR-6 | BN-PR-10 | BN-PR-15 |

| Processing capacity | 3 Tons | 6 Tons | 10 Tons | 15 Tons |

| Reactor size | 1500*3500 mm | 2400*5000 mm | 2600*6600 mm | 2800*8000 mm |

| Pyrolysis time | 3-4 h | 4-6 h | 6-8 h | 8-10 h |

| Feeding time | 0.5 h | 0.7 h | 1 h | 1 h |

| Cooling time | 3-4 h | 4-5 h | 4-5 h | 5-6 h |

| Discharging time | 0.5 h | 0.7 h | 1 h | 1 h |

| Power needed | 12.5 Kg | 18.6 Kg | 32.5 Kg | 35.5 Kg |

| Water consumption | 100 Kg | 300 Kg | 500 Kg | 500 Kg |

| Fuel consumption | 30 Kg/h | 40 Kg/h | 60 Kg/h | 90 Kg/h |

| Area covered(W*L) | 2.3X11.5 M | 8X22 M | 8X30 M | 8X30 M |

| Applicable initial heating fuel | Natural gas/LPG/Diesel/Pyrolysis oil | |||

| Noise(dB) | ≤80dB | |||

| Working process | Batch type | |||

| cooling method | Water cooling | |||

Company Profile

The BNTET renewable energy equipment is a new type of energy-saving and high-efficiency equipment jointly developed by "Heat Technology Energy Company" and "Henan Polytechnic University". The core components of the equipment are all independently researched,designed and produced.

The main products include: pyrolysis furnaces, cracking furnaces, gasification furnaces, carbonization furnaces, incinerators,burners, heat exchangers, oil condensation and recovery devices and their auxiliary equipment. BNTET has a powerful R & D and technical team. Before the production of each piece of equipment, the professor team conducts a 1:1 numerical simulation thermal analysis. Through the numerical simulation of multiple fields such as cold and hot flow fields,temperature fields, and component fields, the structure of the furnace and the structure of the burner are optimized to achieve an excellent theoretical numerical design.

BNTET also has 15 years of experience in designing and producing burners. The burner is a core accessory of the pyrolysis furnace,and its combustion efficiency and combustion stability affect the operation of the entire set of equipment. According to the characteristics of the pyrolysis furnace, BNTET has designed and produced a burner specifically for the pyrolysis furnace.Compared with ordinary burners, it can save more than 10% of energy, provide the most suitable air-fuel ratio, save costs for users, and is safer, more energy-efficient, more efficient and more environmentally friendly.

With a strong theoretical and technical team, years of production practice experience, rich engineering installation experience and a customer-oriented work concept, BNTET is looking forward to achieving win-win cooperation with you!

>> Brand New Hoodie Made To Order From China Supplier

>> Plastic Pet Juice Jug Water Glass Wine Bottle Red Wine Cup Making Injection Blow Molding Machine

>> Hot-DIP Galvanized Filter End Metal Caps Filter Cartridge

>> Car body parts rear door for Nissan G11 Almera Classic 2008 door panel

>> Built-in Gas Stove with Glass Panel, Double Burners Design Home Appliance

>> Hot sale industrial sheep cotton wool carding machine textile wool processing machine sheep wool carding machine

>> Lsuzu Gabbage Truck 5/7/10/12 Cbm for Sale

>> Alcoholic Beverage 330ml Canned Beer with OEM Service Fruit Beer Drinks Relaxing

>> CNC Stone 3D Engraving 4 Axis Machine

>> Outdoor Rock Filter Opener 180 Protector Noise Manhole Mounting Treatment Full Fuel Assy Hydraulic Head Mud Lock Pump Cover

>> Inner Carving 3D Crafts Crystal

>> Wood Pellet Press Machine Wood Pellet Mill with Good Price

>> Taijia High Quality Concrete Resistivity Meter Concrete Potential Detector beton resistivity tester

>> Concrete Stone Crusher Machine Price Multi Cylinder Hydraulic Cone Crusher HP300 Cone Crusher Price

>> Antibacterial High Rebound Molded EVA Insole for Sports Shoes Walking Shoes and Lifestyle Shoes

>> Pear Juice Concentrate with High Quality

>> CNC Horizontal Worm Whirling Miller Machine

>> Nij Iiia Bulletproof Vest Ultra Thin Made with Kevlar Body Armor

>> Fashion Pleated Bucket Bag Women Crossbody Bag Ladies Shoulder Bag

>> Digital Asphalt Non-Nuclear density meter pavement quality indicator

>> Best Seller Microfber Cleaning Spin Magic Wet Washable Flexible 2 in 1 Detachable Bucket Dry Dual-Use Extendable Rotating Mop Set

>> China Guang Zhou Fashion Canvas Cotton Tote Bags with Logo Printing

>> Soap Packaging Paper Wrapping Pillow Packing Machine

>> isolation suit 45g Blue SMS Disposable isolation gown Suit

>> Saw Filter Bag Dust Collector Wood Woodworking

>> High Precision Plane Surface Grinding Machine for Mechanical Seals

>> Multi-Functional 10HP Kama Diesel Power Tiller with CE Certificate

>> 2025 Four-Wheel Drive Tractor, Riding Multi-Purpose Mini Tractor, Compact Agricultural Small Tractor12-18HP

>> South Africa Namibia lump wood charcoal making machine price

>> Versatile Effective Foam Crusher EPS with Hard Teeth Surface Reducer