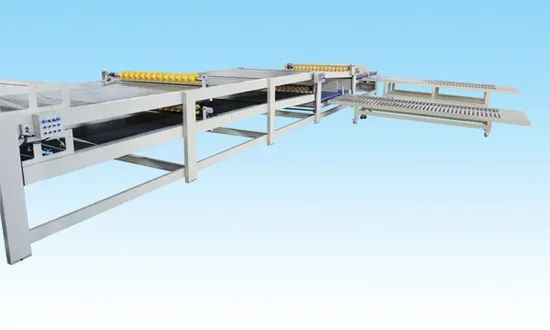

Nc Duplex Counter Stacker, Double Layer

| US$30,000.00-1,000,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

DMT-D

Automation

Automatic

Suitable for

Paper

Paper Thickness

Normal Specification Paper

Operatin Side

Left or Right Make to Customer Rerquest

Electricity Voltage

Made to Customer Request

Transport Package

Plastic Film, Wooden Box

Specification

ISO

Trademark

Yush

Origin

China

HS Code

8441

Production Capacity

10 Sets Per Month

Product Description

NC Duplex Counter Stacker1) DMT-D Double Layer Conveyor Stacker uses the transmission mode: the upper for the vertical transport out of paper; lower for the lateral transfer out of paper

2) Stacker of auto-lifting system, through the accumulation of photoelectric switches can be automatically adjusted according to a high degree of stacked cardboard stacked paper position

3) The lower matching with the horizontal conveyor speed and control; The upper board conveyor machine matched with the gantry stacker or both layer adopt right-angle stacker

3/5/7-layer Corrugated Cardboard Production Line 1) WJ-I/II/III 3/5/7-layer Corrugated Cardboard Production Line consists of the following machines, Electrical Shaftless Mill Roll Stand, Single Preheater, Fingerless type Single Facer, Overhead Conveyor Bridge, Duplex Preheater, Duplex Gluer, Double Facer, Lift-down Thin Blade Slitter Scorer, NC Cut-off, Right-angle Conveyor & Stacker, etc.

2) Kraft Paper Reel to be corrugated and glue by Corn Starch Gum, continuously produce, slit, crease & cut to 3/5-layer Corrugated Cardboard Sheet, and then conveyor, stack and output.

3) The production line has rational structure design, advanced producing flow, high efficiency, strong batch adjustability, easy operation, etc. good work conditions.

4) It is the ideal and perfect equipment for corrugated carton box factories.

| Max Effective Width | 1100~2200mm |

| Max Paper Roll Diameter | 1500mm |

| Max Paper Roll Weight | 3000kg |

| Corrugating Roller | Φ280~405mm, 48CrMo alloy steel, hardness HRC58°-60° |

| Min Slitting Width | 150mm |

| Cutting Length | 500~9999mm |

| Design Speed | 100~200m/min |

| Heating Method | Steam Heating |

| Economic Working Speed | 80~160m/min |

>> High Precision Automatic Gantry Horizontal Metal Plate Special CNC Drilling and Tapping Machine

>> Diesel Sany China Mounted Boom Small 37m Concrete Machine Pump Truck Manufacture

>> Electro Hydraulic Synchronous CNC Press Brake Kcn-40032, Da69t, 6+1 Axes

>> Cashino PTP-II Portable Receipt Printer 58mm Wireless Bluetooth Thermal Printer for Business Trip

>> High Quality M11 Diesel Engine Parts Piston Kit 4024939 4024938 4059949 4059948

>> OEM Private Label Candy Dietary Pure Himalayan Organic Shilajit Gummy Shilajit Gummies

>> Poultry Farm Use Feedstuff Tmr Mixer Machine Cattle Livestock Tmr Feed Mixer Price

>> Automatic Plastic Bag Frozen Food Dumplings Pizza Pasty Toast Bread Tortilla Pillow Type Big Horizontal Packing Machine

>> Diaper Machine

>> Kgs-Wm Programmable High Percision 3 Axis Auto Feed Servo Surface Grinder Machine

>> MAICTOP car accessories car interior for landcruiser 2008 upgrade to 2020 style sliver FJ200 UZJ200

>> Wholesale Shipping From China to New Caledonia (Noumea) by Sea

>> OEM 9518569 Heavy Duty Truck Radiador Intercooler used for Volvo B12

>> Sdlanch New Design CE EPA 1ton Farm Household Construction Small Crawler Excavator Mini Digger for Sale

>> 12n6.5-BS Motorcycle Battery Maintenance Free Lead Acid Battery 12V6.5ah

>> Environment Friendly 70d Plain Nylon Four Way Spandex Water Proof Woven Stretch Outdoor Pant Fabric

>> ATV Tire Mould Tyre Mould Factory with Good Price

>> Metal Plate and Tube Fibre Laser Cutter Multifunction Laser Cutting Machines CNC Fiber Laser Cutting Machine Factory Price

>> High Capacity Wood Flour Milling Machine Powder Soft Powder Grinding

>> 1 Ton Small Track Excavator with Rubber Tracks and Accessories/Mini Excavator/Crawler Excavator with Bucket/Engineering Construction Digger/Disshell/Shovel/Grab

>> Rubber Mill Roll

>> V Belt, Raw Edge Rubber V Belt

>> Low Energy Consumption Plastic PP LDPE LLDPE Film Washing Recycling Machine Plant with Squeezer

>> Centrifugal Casting Production Line for Car Accessories

>> Sandblasting Room / Machinery Factory High Quality / Sand Blasting Booths

>> Plastic Free 4-16oz Paper Cup Making Machine Tea Coffee 150PCS/Min

>> Acoolda Handbag insulated food delivery bags

>> Turret Milling Machine High Precision Hot Sale RAM Type CE High Speed

>> Hot Sales Suspension Parts Stabilizer Link 555403R000 55540 3R000 55540-3R000 Fit For Hyundai

>> 4 Gallon Water Bottle Full Automatic Blow Moulding Machine