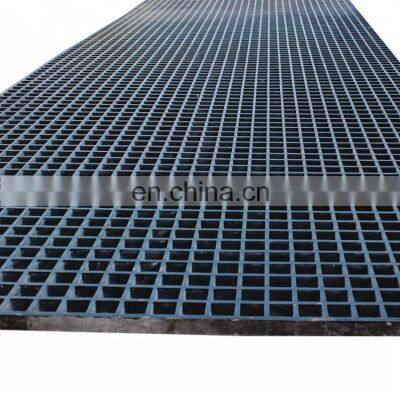

Manufacturer frp fiberglass reinforced plastic grp flooring grating sheet

Product Description

Product DescriptionWe have other different types of products, welcome to inquireProduct Description Manufacturer frp fiberglass reinforced plastic grp flooring grating sheetGlass fiber reinforced plastic (FRP) grid and glass fiber reinforced plastic plate, is a kind of glass fiber reinforced material,unsaturated polyester resin as matrix, through special processing and become a kind of plate material, with lots of blank space FRP gratings can be used as structure materials, used as a corrosion environment of ship deck stair floor trench cover platform plank road with corrosion such as flame retardant non-magnetic insulated colorful sample a variety of alternative style form, etcSpecificationwe have many different surface of frp fiberglass plastic grp flooring grating sheet, such as Concave surface,gritted surface. Flat surface,solid top gritted surface, solid top checker plated surface and so onfrp fiberglass plastic grp flooring grating sheet We have many size for your choice, please check the sheet. if you want please tell me the mesh size, thickness, and your order quantity. then we will give you the best priceSpecifications(mm)a*b(mm)weight(kg)38*38*251220*36605438*38*301220*36607038*38*381220*36601000*4007888150*50*501220*36609819*19*38*38*301075*36267238*38*651030*404014140*40*401010*40408119*19*38*38*381220*36609225*25*50*50*501220*366062Panel size cutting type Normally the whole panel size is 1220*3660mm, if you want to size small than this, we can cut it as your required, Please check the picture, we can cut it Align edges and tooth edgeProduct detailsProduct FeaturesProduct applicationfrp fiberglass plastic grp flooring grating sheet ApplicationAs a new product, FRP grating has the advantages of high strength and light weight. It is suitable for many industries, such as poultry farming, car wash house, tree grate, power plant, trench cover, sewage treatment plant, etc.Production processFRP Molded grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal,and thurougly wettled out with resin,layer by layer. Any process such as post applied grit could be bonded after as a secondary opreration.This continuous process produces an intergral,one piece panel,which offers excellent corrosion resistance as well as bi-directional strength.Process &PackingHello friend, if you need please contact

>> Small Rechargeable Ore Gold Mine Industrial Use Safety Light Cap Lamp Mining LED Headlamp Explosion Proof Safety Helmet Lamp

>> 1000L Pallet Blow Molding Making Machine

>> Ye5 3-Phase Motor High-Efficiency Water Pump

>> Trieffect Falling Film Evaporator Concentrator

>> Aluco ACP Sheet Aluminum Plastic Composite Panel

>> Safety Food Grade Disposable Restaurant Recyclable Kraft Tableware Paper Bag

>> Acrylic Kids Beanie Set with Gloves Scarf

>> TK2060-7 Timing Chain Kit for BMW N42 B18 A/N46 B20 A with oe no.:11348649768;11311439851

>> Vaseline Making Machine Ointment Toothpaste Vacuum Mixer

>> 2 Tier Stainless Steel Wire Rack Wall Mounted Adhesive Magic Sticker Bathroom Storage Shelf Rack

>> CNC Metal Lathe Qk1319 Alloy CNC Lathe Processing

>> Polyester DIY White Car Flag Custom Blank Sublimation Car Flag for Car Windows

>> Factory High Quality Disposable Nonwoven Antiskid Shoe Cover Making Machine by Ultrasonic

>> Commercial Automatic 20-40HP Peanut Harvest Machine for Farm

>> Kids and Adults Fitness Body Building Biggest Trampoline

>> China Manufacturer High Carbon UHP High Power Graphite Electrode 100-700mm

>> Fs662-1500 HPL All-Steel Anti-Static Raised Floor for Computer Room

>> High Quality Shoulder Bag Business Tote Bag Lawyer Laptop Briefcase Lawyer Briefcases for Men Women

>> Advanced Automatic Concrete Mixer Truck with 4.0 Cubic Meter Capacity

>> Custom 400ml 1000ml aluminum foil stand up pouch plastic body wash spout packaging bag liquid laundry soap packaging pouches

>> Good Quality Commercial Glass Entry Door

>> high efficiency biochar making machine with low price

>> BSCI Factory Custom Design Enamel Metal Gold Lapel Pin Badge

>> Rally Machine Open Back Expansion Workout

>> Rubber Sheet Pattern Cutting Machine

>> Bluetooth Marine Sound Bar Outdoor Professional Speaker and Sound Box for ATV&UTV

>> Wholesale Multifunctional Natural Expandable Sides Brown Caddy Bath Bamboo Bathtub Tray

>> 2020 hot sale semi automatic juice filling machine, peanut oil filling machine,Soda filling machine

>> outdoor usage cladding white coating aluminium expanded metal facade

>> Ruihang China Manufacturer Custom Shredder Plastic Machine