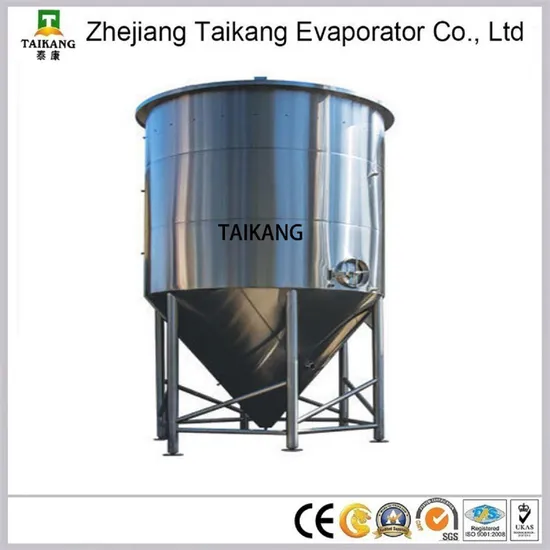

High Quality GMP Standard Chemical Mixing Tank with Agitator System

| US$2,000.00-10,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

TK

Type

Tank Reactor

Material

Stainless Steel

Capacity

501-1000L

Structure

Filling Tube

Pressure

Positive

Agitator Model

Agitator

Tower Reactor Type

Spray Tower Reactor

Heating

Hot Water Heating

Heat Transfer Structure

Jacketed

Automatic Grade

Semi-Automatic

Condition

New

Transport Package

Plywood Case or Film Wrapping

Specification

1160*2350mm

Trademark

Taikang

Origin

Wenzhou City

HS Code

8419899090

Production Capacity

500sets/Month

Product Description

Chemical Reactor is an enclosed volume in which a chemical reaction takes place.In chemical engineering, it is generally understood to be a process vessel used to carry out chemical reaction, which is one of the classic unit operations in chemical process analysis. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency forwards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expense include energy input, energy removal, raw material costs, labor,etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure,frictional pressure loss or agitation.

Main Parameters

| Model Parameter | TKR-300 | TKR-500 | TKR-1000 | TKR-1500 | TKR-2000 | TKR-3000 | TKR-5000 |

| Capacity(L) | 300L | 500L | 1000L | 1500L | 2000L | 3000L | 5000 |

| Diameter(mm) | 900mm | 1160mm | 1350mm | 1500mm | 1550mm | 1750mm | 2000 |

| Height(mm) | 1800mm | 2350mm | 2500mm | 3000mm | 3000mm | 3200mm | 3700 |

Advantages SUS 304, 316 stainless steel material or Tai steel material, sanitary Insulation layer of 2-3 inches as requested Accurate Inner Polishing up to Ra0.45μm Multiple speed choices,fixed speed and frequency inverted. Standard design according to GMP and GB150.1~4-2011 Customized size.

>> Best Price High Speed Plastic Belt Optical Sorter Color Sorter

>> Oil Painting Hot Stamping Film HD 770UV Photo Machine

>> Halchen Hck410 Ton Plastic Crates Making Machine Plastic Boxes Injection Molding Machine

>> Simva LED Filament Bulb Candle Tail C35t 2W (25W Equivalent) 245lm 2200-6500K E14/E27 360degree with Ce Approved

>> Biodegrable Plastic PLA/Pbat/Pbs Granules Corn Starch Filled Compounding Pelleting Line/Plastic Extruders

>> R3G190*45mm Ec Backward Curved Centrifugal Fan For Cabinet air conditioner replace Ebm

>> OEM 20460178 20517350 20722444 65466A 85000765 Original standard aluminum water Radiator used for Vlovo FM9/12 Engine Cooling System

>> CNC Milling Machine, CNC Machine Center

>> OEM Hot Drop Die Forging Alloy Steel Pin Anchor D Shape Shackles

>> Livestock Chicken Pet Bird Animal Food Making Machine 1mm-12mm Feed Pellet Extruder Floating Sinking Tilapia Fish Feed Processing Machine

>> Bullet Type PVC Yellow Color Fishing Floats for Fishing Tackle

>> Carbon Seamless Steel Pipe St52 Cold Drawn Transmission Shaft Tubes

>> M820 Surface Grinding Grinder Machine with Ce Certificate

>> High-Speed Manufacturer Plastic Powder Granule Mixer Automatic Mixing Conveyer Metering for PVC UPVC Floor Profiles and Pipes for Extruder Machine

>> 100kg Feed Pellet Machine Poultry Food Making Machine

>> Red Swan Water Resistant Canvas Duffel Handbag Germany Design Sport Canvas Travelling Bag (RS-2032K-1)

>> China Liya 4.2-6.5m Foldable Inflatable Fishing Boat with Motor

>> patio 3x6 roof aluminum pergola motorized

>> Heavy-Duty Deep Loosening Subsoiler 1s-250A for Efficient Soil Aeration

>> Modern european design luxury carved wood door furniture accent kitchen cabinet

>> 1meter 3 In 1 Magnetic USB Fast Charging Usb Data Cable

>> FT8210H Magnetic Flow Converter Water Flowmeter PCB Board Of Magnetic Flow Meter Electromagnetic-Inductive Flow Sensor

>> High Quality 1: 1 Jl Go2 Go3 Speaker Wireless Bluetooth Audio Loudspeaker

>> Emblem 44mm Square Promotional Button Badge, Plastic Pin Back Badges (PBB005)

>> New trendy automatic products black instant coffee powder filling machine

>> High Quality Four Wheels Capacity Steel 300kgs Black Platform Hand Truck Trolley

>> Hammer Mill Machine Stone Mini PC Hammer Crusher Vertical for Rock

>> High Capacity and Adjustable Fineness Ultrafine Grinder

>> South America Hot Selling High Availability Factory Shredder Small Double Shaft Shredder Waste Wood Shredder with Best Price

>> Plastic HDPE Bottle Production Extrusion Blow Molding Machine Tonva