DIN K St Steel Cord Fire Resistant Rubber Conveyor Beltst800 Conveyor Belt

| US$10.00-15.00 | 100 Meters (MOQ) |

Basic Info.

Model NO.

OEM

Usage

Transport Goods

Performance

Strong Rubber Conveyor Belt

Supply Ability

10000 Meter Per Month

Color

Black

Material

Rubber

Transport Package

International Packing

Specification

ISO, CE OR OEM

Trademark

SHUOLONG

Origin

Shandong, China

HS Code

4010190000

Production Capacity

10000 Meter Per Month

Product Description

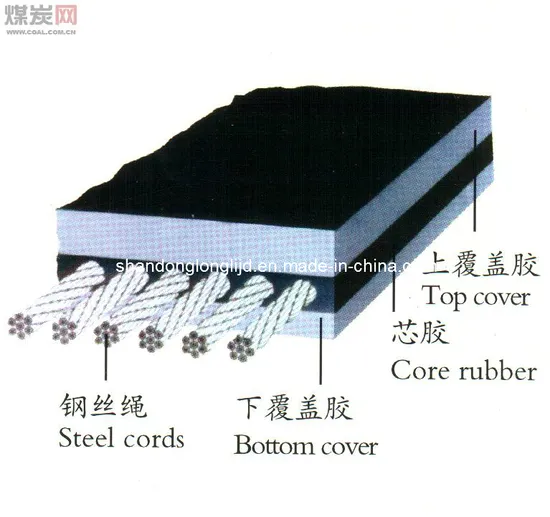

DIN K ST Steel Cord Fire Resistant Rubber Conveyor BeltProduct Desription

1. Physical Properties of Rubber Cover (DIN22131)

| Grade | Tensile Strength/Mpa ≥ | Breaking Elongation/% ≥ | Abrasion Loss/mm3 ≤ |

| W | 18 | 400 | 90 |

| X | 25 | 450 | 120 |

| Y | 20 | 400 | 150 |

| K | 20 | 400 | 200 |

2. Safety Property

| Item | Fire resistant properties |

| Alcohol burner test | Average value of flame duration of 6 samples without covers, not more than 5s, any single value not more than 15s. |

| Anti-static test | Surface resistance ≤ 3×108Ω |

3. Specification of Steel Cord Conveyor Belt

| Belt type | ST/S 630 | ST/S 800 | ST/S 1000 | ST/S 1250 | ST/S 1600 | ST/S 2000 | ST/S 2500 | ST/S 2800 | ST/S 3150 | ST/S 3500 | ST/S 4000 | ST/S 4500 | ST/S 5000 | ST/S 5400 |

| Min. tensile strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

| Max. diameter of steel cord (mm) | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

| Min. Top/Bottom cover thickness (mm) | 5.0 | 5.0 | 6.0 | 6.0 | 6.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 | 8.5 | 9.0 |

| Belt width | Number of steel cord | |||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 114 | 117 | 117 | 109 | 102 | 102 |

| 2000 | 196 | 196 | 159 | 159 | 159 | 159 | 128 | 128 | 128 | 130 | 130 | 121 | 113 | 113 |

| 2200 | 216 | 216 | 176 | 176 | 176 | 176 | 141 | 141 | 141 | 144 | 144 | 134 | 125 | 125 |

Application

Massive task steel cord conveyor belt for general use is widely used in coal, mine, port, metallurgy, power, chemical industries and suitable for high strength,long distance and heavy load transportation of materials. The product is excellent for long distance, high abasion, high impact/tensile strength with longer service life, more excellent durability. Its cover grades are GB-L, GB-D, GB-H, and DIN Z, W, Y, X.

Features:

1. High tensile strength

2. Small elongation in use

3. Lesser elongation in use

4. Good troughabilit

Applications:

It is widely used in material delivery for coal/coke, mine, harbour, metallurgy, electric power and chemical industry.

| Specification | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 | ST6300 |

| Tensile Strength (N/mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 |

| Max Diameter of Cord(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7.5 | 8.1 | 8.6 | 8.9/ | 9.7 | 10.9 | 11.3 | 12.3 |

| Pitch of Cord(mm) | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 | 18 |

| Top Rubber Cover Thickness (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 |

| Bottom Rubber Cover Thickness (mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 |

| Width (mm) | Cord Number | |||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | |||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | 54 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 77 | 77 | 71 | 66 | 66 | 63 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 90 | 90 | 84 | 78 | 78 | 74 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 104 | 104 | 96 | 90 | 90 | 85 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 117 | 117 | 109 | 102 | 102 | 96 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 128 | 130 | 130 | 121 | 113 | 113 | 107 | ||

| 2200 | 176 | 141 | 141 | 144 | 144 | 134 | 125 | 125 | 118 | |||||

| 2400 | 193 | 155 | 155 | 157 | 157 | 146 | 137 | 137 | 129 | |||||

| 2600 | 209 | 168 | 168 | 170 | 170 | 159 | 149 | 149 | 140 | |||||

| 2800 | 184 | 184 | 171 | 161 | 161 | |||||||||

Cover rubber property and grades :

| Test items | Property indexes | |||||||

| GB9770-2001 | DIN22131 | |||||||

| D | H | L | P | W | X | Y | ||

| Tensile strength | Mpa >= | 18 | 25 | 20 | 14 | 18 | 25 | 20 |

| Pull to break the elongation rate | % >= | 400 | 450 | 400 | 350 | 400 | 450 | 400 |

| after aging(70°C,7D) Change rate of tensile strength Change rate of elongation | % | -25~+25 | -25~+25 | -25~+25 | 25~+25 | -25~+25 | -25~+25 | -25~+25 |

| Abrasion | <= | 90MM 3 | 120MM 3 | 150MM 3 | 200MM 3 | 90MM 3 | 120MM 3 | 150mm 3 |

>> Taijia 0~15m Digital Level Meter the probe level transmitter Boiler Water Level Sensor

>> Security Environmental Burden Reduction Passenger Car Tire Processing Plant Waste Tire Recycle Tyre Pyrolysis Plant

>> Glass Factory Moving Lifting Lifter Vacuum Lifter Sucker Glass Machine Equipment Machinery 800kg Capacity Glass Loading Electrical Glass Lifter

>> PVC LDPE HDPE Pulverizer Machine PVC Milling Machine Plastic Grinder Grinding Machine PVC Powder Making Machine Plastic Pulverizer Machine

>> New Sinotruk HOWO 6X4 6X6 Airport Water Tank Pump Fire Extinguisher Fire Fighting Truck Price Fire Truck

>> Stainless steel wire aluminum metal mesh Expanded Metal mesh

>> Outdoor Corten Steel Rusty Metal Distinctive Design Garden Decoration Light

>> Solid Wood Cafe Customized Sizes Square Hard Solid Wood Restaurant Furniture Sets

>> M-Type Horse Saddle Stainless Steel Saddle Pipe Clamps

>> New Crop Sunflower Seed Kernels Confectionary Healthy

>> Cheap Custom Multicolor Cute Memo Pads Simple Design Sticky Notes

>> Waterproof DC24V DMX RGB Pixel LED Panel Milky Aluminum Alloy Shell LED Panel Light

>> Sea Water Corrosion Resistant PTFE Sewing Thread for Ship Cover Ship Pad

>> Cayken Diamond Core Drill Machine Scy-3050

>> Middleford Acoustic Grand Piano with Piano Bench and Accessories

>> Factory Automatic Sticker Water Bottle U Tax Stamp Labeling Machine

>> High Configuration Lightweight Design Power Battery 60V80ah Electric Scooter Lithium Battery

>> Magnetic Therapy Posture Corrector Brace Supporter Shoulder Back Support Belt

>> Plastic Granule Mixing Machine for Spc Vinyl Flooring

>> Wholesale Bulk Custom Logo Breathable Sweat-Wicking Socks Compression for Men Women

>> 2015 New Roofing Material (Wooden Tile)

>> Hualong Stone Machinery Digital Template Scan Tool System Measuring Laser Templator for Kitchen Countertops Stairs

>> Quality Fireproof Aluminum Perforated Metal Ceiling for Library University Decoration

>> C2xy, Ca2xy Power Cables with XLPE Insulation and PVC Sheathiec 60 502-1 (Cu/XLPE/PVC, Al/XLPE/PVC, C2XY, CA2XY)

>> Taijia Concrete Rebar Steel Bar Scanner Detector concrete rebar locator detector rebar detector

>> Wholesale Cell/Mobile Phone Replacement LCD for Nokia Lumia 530

>> Double Safe Military Police Enforcement Outddor Duty Tactical Belt

>> Used Tower Crane7025-12e

>> Cheap Mineral Wool Decoration Ceiling Board

>> Fmc High Pressure Horizontal Multistage Booster Centrifugal Water Pump High Lift Head Multi Stage Dewatering Pump