12V 22W Qi Car Wireless Charging Module Printed Circuit Board Vehicle Specification Grade Outdoor Power Modification PCBA with CE FCC Certificate

Basic Info.

Model NO.

YCTBJ-001

Layers

Multilayer

Base Material

FR-4

Certification

ISO, CE, FCC

Customized

Customized

Condition

New

Transport Package

Bubble Anti-Static Bag

Specification

PCB: 14*55*4.7 mm, Coil + ferrite: 94*52*3.7 mm

Trademark

YCT

Origin

China

HS Code

8504500000

Production Capacity

100000piece/Year

Product Description

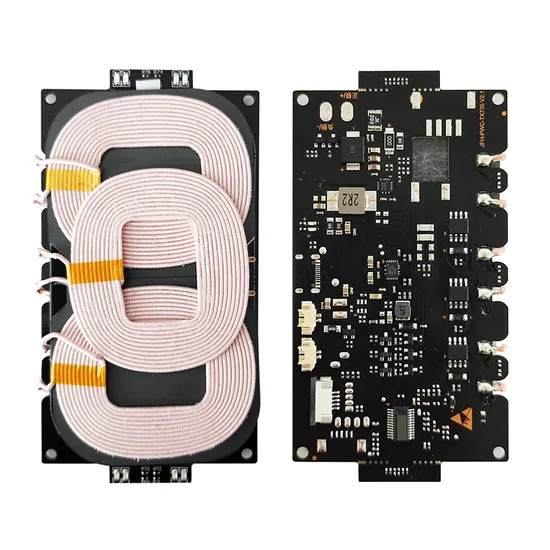

Product DescriptionProduct Model: JFH-PWC-TX735

Transmission distance: 0-8mm between objects, 0-10mm between spaces (not chargeable between metal materials)

Input voltage: welding line: 10-24V, it's ok to customize 10-32V voltage input (no need regulator, can connected to the car directly )

Output power: 22 W

Output currency: 1.7A

Charging power: (1) input 5V, output 5W: input 9V, output 15W; (2) input 12V/QC3.0: output 20W-5W auto identification

Coil size: 94*52*thickness 3.7mm

PCB size: 104*55*thickness 4.7mm

Charging standard: QI wireless charging standard

Certification: CE/KC/FCC/ROHS and other certificates

Custom Production Capacity

PCB custom capacity

| Item | Mass Production | Pilot Run Production |

| Capacity | Capacity | |

| Layer Counts | 1L-18L, HDI | 20-28 , HDI |

| Material | CEM1,CEM3,FR-4, High TG FR4 , Halogen-free FR4 , aluminium ,Ceramic(96% Alumina) | |

| PTFE(F4B,F4BK), Rogers(4003,4350,5880)Taconic(TLX-8,TLX-9), Arlon(35N,85N)etc. | ||

| Material Mixed Laminate | 4 layers -- 10 layers | 12 layers |

| FR4+Ro4350 , FR4+Aluminium , FR4+ Polyimide | ||

| Maximum Size | 610mm X 1200mm | 1200 - 2000MM |

| Board Outline Tolerance | ±0.15mm | ±0.10mm |

| Board Thickness | 0.125mm--6.00mm | 0.1mm--8.00mm |

| Thickness Tolerance ( t≥0.8mm) | ± 8% | ±5% |

| Thickness Tolerance( t<0.8mm) | ±10% | ±8% |

| Minimum Line / Space | 0.10mm | 0.075mm |

| Trace width Tolerance | 15%-20% | 10% |

| Minimum Drilling Hole (Mechanical) | 0.2mm | 0.15mm |

| Minimum laser hole | 0.1mm | 0.075mm |

| Hole Position/hole Tolerance | ±0.05mm PTH:±0.076MM NPTH:±0.05mm | |

| Mini hole ring (single | 0.075MM | 0.05MM |

| OutLayer Copper Thickness | 17um--175um | 175um--210um |

| InnerLayer Copper Thickness | 17um--175um | 175um--210um |

| Mini Solder Mask Bridge | 0.05mm | 0.025mm |

| Impedance Control Tolerance | ±10% | ±5% |

| Surface Finishing | HASL, Lead free HASL, Immersion gold, Immersion tin, Immersion Silver. | |

| Plated gold , OSP, Carbon ink, | ||

| Acceptable File Format | ALL Gerber Files,POWERPCB,PROTEL,PADS2000,CAD,AUTOCAD,ORCAD,P-CAD,CAM-350,CAM2000 etc. | |

| Quality Standards | IPC-A-600F and MIL-STD-105D CHINA GB<4588> | |

PCBA custom Capacity

| Stencil Size | 736x736mm |

| Minimum IC Pitch | 0.2mm |

| Maximum PCB size | 510X460mm |

| Minimum PCB thickness | 0.5mm |

| Minimum chip size: | 0201 (0.2x0.1)/0603 (0.6 x 0.3mm) |

| Maximum BGA size: | 74x74mm |

| BGA ball pitch: | 1.00mm (minimum), 3.00mm (maximum) |

| BGA ball diameter: | 0.40mm (minimum), 1.00mm (maximum) |

| QFP lead pitch: | 0.38mm (minimum), 2.54mm (maximum) |

| Machine Type | Panasonic CM 402 |

| Panasonic DT301 | |

| Panasonic CM 402 | patch speed:0.06sec/ chip (up to 60,000cph) |

| Patch precision:±0.03~±0.005mm | |

| PCB size:max:510X460mm,min:50X50mm | |

| element size: 0603mm-50X50mm | |

| Panasonic DT301 | patch speed:0.7sec/ chip |

| Patch precision:±0.03~±0.005mm | |

| PCB size:max:510X460mm,min:50X50mm | |

| element size: 1005mm-100X90mmX25mm high speed multifunctional mounter | |

| Volume: | One piece to low volume production quantities |

| Low cost first prototype Fab | |

| Fast deliveries | |

| Assembly type: | SMT assembly |

| DIP assembly | |

| Mixed(surface mount and through hole) technology | |

| Cable assembly | |

| Components type: | Passive components |

| As small as 0402 package | |

| As small as 0201 with design review | |

| Ball Grid Arrays(BGA): | |

| As small as .5mm pitch | |

| Component source | Shar,poshiba, ST, |

| Samsung, Infineon, Ti, | |

| ON,Microchip etc. | |

| Parts procurements: | provide one-stop services |

| Only Assembly service (you supply the parts) | |

| You supply some parts(expensive/important components), we do the rest | |

| Solder type: | Leaded |

| Lead-free/ROHS compliant | |

| Other capabilities: | Repair/rework services |

| Mechanical assembly | |

| Box build | |

| Mold and plastic injection. | |

| Testing Type | First prototype test before mass quantity production |

| AOI | |

| BGA X-ray | |

| PCB E-test | |

| Lead time | According Digikey components delivery time |

Packaging

Strong pac kaging, not easily to be damaged or deformed during the long-distance transportation.

Contact

Please click the following to send us message, thank you!

>> FIBC Bulk Bag PP Woven Big Bag Bulk Jumbo Bag Ton Bag

>> Super Large 1000HP Weichai Baudouin Diesel Marine Engine Assembly with Factory Price

>> Manual Lathe Precision Bench Lathe for Mechanical Metal Work and Turning

>> Laser Welding Machine Laser Welder 1000W for Metal Stainless Steel Aluminum

>> CF-1L Cheap High Production Rubber Dispersion Mixer Kneader for Manufacturing Plant

>> Double Wire Cord End Terminal

>> Foska Popular High Quality 12 Digit Solar Power Office Calculator

>> Big Sale! Single Head China Factory Embroidery Machine Price Made in China

>> Electric actuator accessories B+RS forward and reverse drive intelligent module

>> Youlong Simple Design 52.75pint/D 230V Portable Dehumidifier FOR Hotel auto drain water tank full stop compressor protection

>> Pre-Paid Multification Electrical Meter with IP45/60

>> 16oz, 20oz, 24oz One-Piece Straight Claw Hammer (WW-CH05)

>> Wholesale Custom 3D Silicone Logo Stickers Heat Transfer Printing Labels for T-Shirts

>> New Product High Power Lead Acid Motorcycle Mf Starting Battery 12V 4ah 5ah 7ah 9ah Ytx12 Start Motor AGM Battery

>> Negotiable Customized Riha Offer Plastic Injection Mold Rotary Clip Dampers

>> Disposable nonwoven surgical gowns CPE waterproof surgical clothes

>> High Quality Plastic Data Strip for Supermarket

>> Powerful Aluminium Alloy Electric Motorcycle Electrical Scooter Max Speed 80km/H Range 180km

>> Industry by Container China Textile Quality Assured Paper Cone Machine

>> 4000kg 3meters Grey Polyester Lifting Webbing Sling Eye to Eye Double Ply

>> New 2 Row Tractor Belt Mini Small Automatic Garlic Onion Carrot Sweet Potato Harvester

>> Factory Price 40W 2100nm Medical Urology Laser Surgical Ho YAG Holmium Laser Lithotripsy

>> Sunflower Oil Production Line Manufacturer

>> Automatic Precision Solid-Liquid Separation Disc Centrifuge

>> Professional ABS PC PP PA PE PVC Plastic Injection Mold Maker Mould OEM

>> Supply Flexible Copper Clad Laminate Fccl Application Polyimide Film

>> Single Open Width Circular Knitting Machine High Efficiency Knitting Machine

>> New Arrival 26cm Tri-Ply Stainless Steel Non-Stick Honey Comb Saute Pan Cookware

>> Good Service CNC/Mnc Machining Center Vertical CNC Gantry Milling Machine with CE

>> ASTM D1657 Density or Relative Density of Liquefied Petroleum Gas Tester