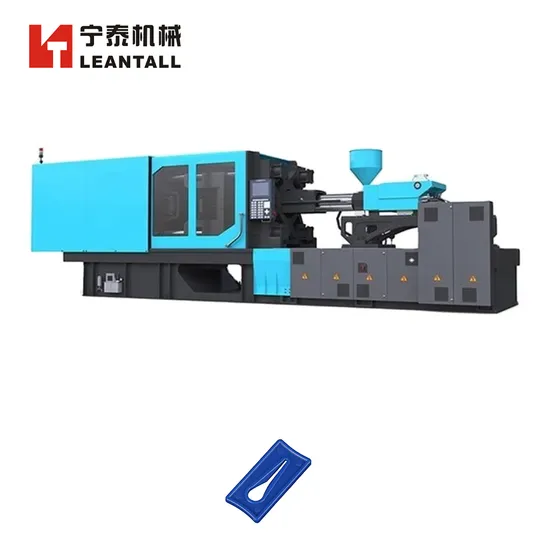

330t Leantall Cup Making Injection Molding Machine Shot Volume (theoretical) 1350 Robot

Basic Info.

Model NO.

NT330

Type

Preform Injection

Structure

Horizontal

Plastic Type

Thermoplastic

Plasticizing Way

Plunger Type

Clamping Way

Hydraulic

Automation

Automatic

Computerized

Computerized

Certification

ISO9001:2008

Marketing Type

Hot Product

Core Component

Motor, PLC

Material

Stainless Steel

Applicable Industrial

Manufacturing Plant

Voltage

380V/50Hz 3p+N+E(Alterable)

Function

Plastic Parts Production

Mold

Can Be Customizable

Clamp Force

3300kN

Space Between Tie Bars

730*670

Transport Package

at Seller′s Option

Specification

7.2m*1.85m*2.35m

Trademark

Leantall

Origin

China

Production Capacity

20sets/Month

Packaging & Delivery

Package Size

720.00cm * 185.00cm * 235.00cm

Package Gross Weight

12000.000kg

Product Description

Product Parameters

| Part | Name | Unit | NT330 | ||

| Injection Unit | SCREW DIAMETER | mm | 65 | 70 | 75 |

| SCREW L/D RATIO | L/D | 22 | 20 | 19 | |

| INJECTION STROKE | mm | 350 | 350 | 350 | |

| NJECTION SPEED | Mm/sec | 97 | 97 | 97 | |

| SHOT VOLUME(THEORETICAL) | CM3 | 1161 | 1347 | 1546 | |

| INJECTION WEIGHT(PS) | g | 1056 | 1225 | 1406 | |

| INJECTION PRESSURE | Mpa | 202 | 174 | 152 | |

| INJECTION RATE | cm³/sec | 321 | 373 | 428 | |

| SCREW SPEED | rpm | 189 | |||

| Clamping Unit | CLAMP FORCE | Kn | 3300 | ||

| OPEN STROKE | mm | 669 | |||

| SPACE BETWEEN TIE BARS | mm×mm | 730X670 | |||

| MAX.MOULD HEIGHT | mm | 680 | |||

| MIN.MOULD HEIGHT | mm | 250 | |||

| EJECTOR STROKE | mm | 160 | |||

| EJECTOR FORCE | Kn | 70 | |||

| EJECTOR NUMBER | N | 9 | |||

| Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

| SEVRO DRIVE POWER | Kw | 55 | |||

| HEATING POWER | Kw | 22.5 | |||

| MACHINE DIMENSION(L*W*H) | m×m×m | 7.2*1.85*2.35 | |||

| MACHINE WEIGHT(ESTIMATE) | T | 12 | |||

Product Description

Packaging & Shipping

Company Profile

Our Advantages

Q: Are you manufacturer or trading company? A: We are manufacturer with decades experiences,located in Zhejiang province. Q: What is the product range? A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc. Q: Where is your main selling market? A: We have business domestic,USA,Russia,Indonesia,Egypt,Turkey ,Uzbekistan, Pakistan,etc. Q: Will you offer field installation and operator training at the buyer's factory? A: Yes,we will arrange our skilled engineers for filed installation and training. Q: What is the delivery time(equipment production time)? A: It will be ready around 50 days after getting mutual confirmation about the order details and prepayment. Q: Do you also have source for molds and spare parts? A: Yes,we can offer with the competitive quality and reasonable price. Customized as required. Q: What is the standard of package? A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

>> Wooden Pallet Making Machine Corner Cutter Machine

>> Tape High Quality Measuring Tape with Auto Lock

>> Hanmix PCR Passenger Car Tyres 4X4 at/Mt/UHP/LTR Gcc Saso Factory Wholesale (205/60r15 205/65r15 215/55r17) Hot Sale Light Heavy Truck TBR Tires for Good Price

>> aluminum hurricane proof frosted glass modern new black sectional panel remote control automatic lift garage door

>> car spare parts front wheel hub bearing assembly for ford 1370437

>> Half Face Safety Mask Anti-Dust Personal Respiratory Protection Industrial Gas Mask

>> Vacuum Auto-Load Raw Material Vacuum Auto Loader 300g Auto Hopper Loader

>> Gym Training Fitness Mitt Padding Weight Lifting Sports Yoga Gloves

>> Used Speed 56m High Truck Mounted Mobile Concrete Trailer Pump

>> 500ml 1L 5L 7L Small Scale Semi Automatic Water Oil Wine Juice Plastic Pet Bottle Jar Can Blowing Moulding Machine Factory Price

>> Vmc-850 CNC Vertical Machining Center Metal Lathe CNC Milling Machine

>> Customized CNC Polyamide Sheet Wear resistant Corrosion Resistant Heat Resistant PA6 GF15 for Electrical Connector

>> 12V for Audi A8 2.5 2.8 3.0 Sves082417 0124515058 0986044310 2542233A 038903018f 059903015fx 06c903018X AC Car Alternator

>> SS304 SS316L Stainless Steel Liquid Soap Making Machine in South Africa

>> 2.4 Inch Display Screen Anti-Peeping E-book Calculator, Support Sound Recording / Radio / Music & Video Playingno Reviews Yet

>> A360 ADC12 Die Casting Aluminum Die Casting Auto Spare Parts

>> Customer Customization Tire Vulcanizing Equipment for Car Repair Car Tire Repair Vulcanizer

>> Gmt Fiber Glass Pallet for Concrete Brick Block Making Machine Made in China

>> Best Selling Single Cylinder Rotary Cooler

>> Heavy-Duty Bridge Saw Block Cutting Machine for Precision Hardware

>> KITA brass marine propeller for boat outboard

>> Gipper Bar Gt-1304 for Offset Printing Machine Spare Parts

>> Computer Logo Hat Custom 3D Malti 1 Haid Embroidery Thread Multi Colour Embroidery Machine Computerized

>> Hot Sale 4-Leaf Clover Stone Lavander Turquoise Sodalite for Van Cleef Necklace

>> PVC White Basin with Mirror Bathroom Sanitary Cabinet

>> IP67 Waterproof Impact Resistant Hard Plastic Protect Case for Gopro Camera

>> Gdgm-3015nc Is a Fixed Beam and Fixed Column Gantry Machining Center Machine Tool Aerospace, Shipbuilding, Power Generation

>> Continuously Working, Stable Performance, Longer Lifetime Wood Sawdust Hammer Machine

>> Surface Grinding Machine Mk1224 Automatic CNC Tool Grinding Machine

>> Automatic Financial Book Paper Binding Machine