Easy to Operate LPG Cylinder System for Enhanced Production Efficiency

| US$50,000.00-200,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

LISHENZW-001A

Function

Storage Pressure Vessel, Separation Pressure Vessel, Heat Pressure Vessel, Reaction Pressure Vessel

Application

Liquefied Gas

Material

Stainless Steel

Pressure

1.6MPa≤p<10.0MPa

Storage Medium

Moncombustible/Nontoxic

Pressure Level

Medium Pressure (1.6MPa≤p<10.0MPa)

Condition

New

Volume (M³)

Customized

Key Selling Points

Easy to Operate

Design Pressure(MPa)

Customized

Core Components

PLC, Engine, Bearing, Gearbox

Place of Origin

Tai′an, Shandong

Max Working Pressure(MPa)

Customized

Design Standard

Customized

Product Name

LPG Production Line

Outer Material

Steel

Dimension(L*W*H)

Customized

Inner Material

Steel

Transport Package

Plastic Net

Specification

Customizable

Trademark

TAIAN TITAN

Origin

Tai′an, Shandong

Production Capacity

30 Sets/Month

Product Description

Product Description

High-Efficiency Production: This world-class gas cylinder production line is innovatively designed to deliver unparalleled high-output production. Capable of producing an impressive [X] gas cylinders per hour, it dramatically elevates production efficiency, adeptly catering to the large-scale production requirements of gas cylinder manufacturers.Advanced Technology: This production line is a marvel of modern engineering, equipped with cutting-edge manufacturing technology. It guarantees high-quality cylinder creation using advanced welding techniques like automatic argon arc welding, ensuring maximum airtightness and robust strength of gas cylinders, thereby minimizing the risk of gas leaks. Precision Manufacturing: Utilizing high-precision machinery and state-of-the-art automated control systems, this line achieves exceptional dimensional accuracy of ±[X]mm in the gas cylinders produced. This precision ensures product standardization and interchangeability, facilitating efficient inventory management and superior after-sales service.

1. Sheet Metal Processing: The production journey begins with the selection of premium steel sheet metal. It is meticulously cut to the required dimensions using a high-precision laser cutting machine and skillfully rolled and molded into the cylinder body through a series of sophisticated forming equipment.

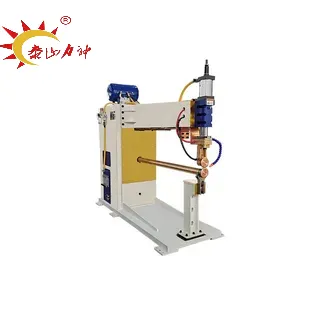

2. Welding Process: Following the formation of the cylinder body, the longitudinal and circumferential welds are expertly executed by automatic welding equipment. This welding process adheres strictly to international standards, with the weld quality rigorously inspected using advanced non-destructive testing methods like ultrasonic and X-ray testing, ensuring the utmost safety and reliability of the gas cylinders.

3. Surface Treatment: Every gas cylinder undergoes a comprehensive surface treatment regimen, encompassing sandblasting, thorough rust removal, primer coating, and finishing with a top-quality paint job. This treatment process not only enhances the aesthetic appeal of the gas cylinders but also significantly boosts their resistance to corrosion, thereby extending the product's service life.

Product Parameters

| Material | Stainless Steel ; Gavalized Steel | Compressed Air Pressure | 0.45MPa |

| Production Line | Non Pressure Water Tank &Pressure Water Tank | Transmission Type | Flexible |

| Certification | CE | Rhythm | Flow Production Line |

| Transport Package | Container | Rated Voltage | 380VAC 50Hz |

Detailed Photos

Company Profile

Certifications

FAQ

>> RF 4.3-10 conectores de rosca en microdin para 1 / 2 cable superflexible 7 / 8 Din 7 / 16

>> China Victor Blow Job 10 Ml Plastic Bottles Making Machine

>> Large Telescopic Range High-Pressure Equipment Single-Arm Low-Temperature LNG Marine Loading Arm with Swivel Joint

>> Factory Electric Insulator Injection Machine Rubber Injection Molding Machine Atuomative Supplies Machine

>> Alsafe 150bar Aluminum CO2 Cylinder for Beverage Service

>> Pet Plastic Bottle Press Machine Plastic Machine Aluminum Can Baler Machine

>> Polyamide Bar Extrusion Mold for PA66 Plastic According to Customers′ Requirements Extrusion Tool

>> muffin hot dog machine

>> The Intelligent NMP Distillation System Can Optimize The Process Automatically

>> Manufacturers Direct Sale Baling Machine Accessories Lever

>> AC DC Power Cord/Charging Cord Injection Molding Machine

>> Fiber Optic Distribution Box 24 Cores FTTH Optical Fiber Terminal Box for Splitter 1: 16/2: 8 Wall Mounting Fiber Box 24 Ports Outlet Fibers

>> High Spead Fully Automatic KN95 Face Mask Machine

>> Hot sale Aluminium Alloy glass bifold door puertas de cristal para exterior waterproof Design folding door for restaurant

>> Factory Direct Sales Cheap Price Stainless Steel/ Carbon/ Brass/Copper Customized Nuts

>> Efficient 12V 10A Smart AGM Battery Charger for Quick Charging

>> Yada 185mm Natural Biodegradable Bulk Birch Wooden Spoon/Fork/Knife Disposable Wooden Cutlery kit

>> Automatic Used Tire Recycling Machine/Used Rubber Recycling Machine

>> Popular 4.4 Inch Electronic Kids LCD Writing Board Drawing Tablet

>> High Production Capacity Plastic Film Granulator PC Plastic Granules Machine Recycling Plastic Granulating Machine Line

>> Weida 12V5ah Motorcycle Dry Charged Battery

>> Wholesale Promotional Gifts Custom Printing Laser Logo House Shape Die-Casting Blank Sublimation Zinc Alloy Rotatable Wood Metal Beer Bottle Opener Keychain

>> Russian Spanish English German 4G Kids GPS Smart Watch Video Call GPS Sos Games Kids Smartwatch Camera for Boys and Girls

>> Gedeli Modern Insulated Front Entrance Doors Design Swing Aluminum Casement Door with Glass

>> UKCA integrated air conditioning in the box

>> Ubox0024 - New Model Metal Furniture Smart Parcel Delivery Express Locker with Electronic Software System

>> Charming Perfume Body Lotion & Body Mist Gift Set Fragrance Mist & Body Cream Perfect Birthday Gift Set for Luxury Body Care Christmas Body Lotion Mist Set

>> Atess All in One Energy Storage System Inverter 30kw 50kw 100kw 150kw Hybrid Inverter HPS 100 150 Solar Power Inverter for Solar Panel System

>> Yellow Signal Lane Signals Forido Wooden Box Package Warning Red Light

>> Electrical Operation Room Bed Surgical Table Electric Operating Table for Hospital Use