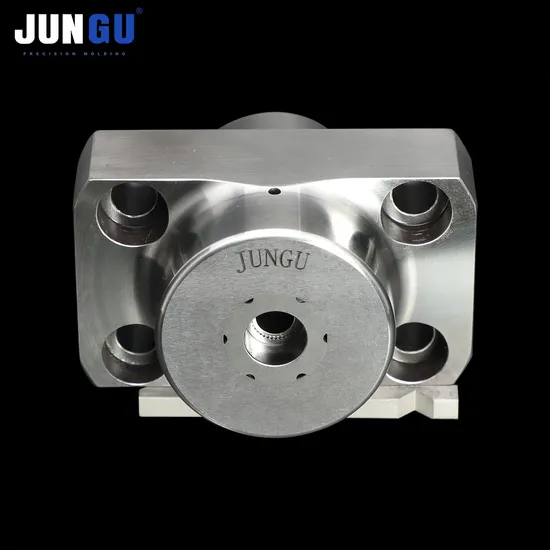

M22 1.5 Die Colding Heading Nut Die Customization Color Mould

Basic Info.

Model NO.

JG-ND-381-1

Craftwork

Polishing

Forging Work Steps

Preliminary Working>Press Fit>Finish Machining

One-time Molding

Not One-time Molding

Certification

ISO

Warranty

Product Life Based on Production Environment Habit

Metal Color

Nature Metal

Customized

Customized

Condition

New

After-sales Service

Yes

Weight

Based on Customed

Precision

High Precision

Transportation

by Air/Sea/Railway

Delivery

According to The Order Quantity

Sample Support

Yes

Main Products

Fastener Die;Nut Die;Bolt Die;Screw Die;Pin Punch;

Transport Package

Carton

Specification

Custom box gauge

Trademark

JUNGU

Origin

Jiangsu, China

HS Code

8207300090

Production Capacity

100, 000PCS

Packaging & Delivery

Package Size

20.00cm * 25.00cm * 30.00cm

Package Gross Weight

10.000kg

Product Description

Product DescriptionPrime Carbide Die Nut Mold Manufacturer Tungsten carbide nut die is mainly composed of tungsten carbide insert and high speed steel die case. Tungsten carbide has the characteristics of high strength, high abrasion resistance, high hardness, high temperature resistance, etc., which can effectively improve the service life of the mould and at the same time, it can also meet the production of different materials of nuts. Our nut dies are of good quality, high precision and quick delivery. We are looking forward to cooperating with you!

| Product Name | Die nut/die nuts/nut die |

| Material | Tungsten carbide and High-speed steel |

| Accuracy | High-precision(0.005) |

| Color | Metal nature |

| Roughness | RA0.1 |

| Advantage | High hardness,high wear resistance,high heat-resistance |

| Lead time | Shortly lead time(around 15 days,10 days are available for a small number of urgent order) |

| Service | Customization,Design and optimization capability for improvement of mould life |

| Application | High strength automotive fasteners, auto parts, engineering forging parts, rail transit rivets, aerospace rivets, tensile mold products, and all kinds of standard cold heading molds. |

| Certification | ISO9001:2015 |

| Processing methods | Cold heading, warm heading, hot forging, cold extrusion, stretching. |

| Equipment | CNC Lathes, CNC inner hole grinding machines,CNC cylindrical grinding machines, CNC Wire cutting,etc. |

Company Profile

Founded in 2014, JUNGU is a professional precision fastener mold manufacturing enterprise integrating design,production, sales and service.

Our factory covers an area of 10,000 square meters and have 120 employees,6 technicians,12 engineerers,5 people after sale sevice team and 178 equipments. The company mainly produces cold heading molds, including multi-station boltand nut molds, cold extrusion molds, and vertical forging molds.

Suzhou Jungu precision mould Co.,Ltd is a professional fastener mold manufacturer with 10 years of experience in molding industry.We have advanced production lines and a team of experienced stuff. We provide a full range of solutions for all kinds of cold heading mould, including multi-station bolt and nut mould, cold extrusion mould, vertical forging mould.

Throughout the entire production process,we take strict quality control measures including raw materials inspection,production process monitoring and final product testing.We have built cooperation with many brands around the would.Such as EJOT,NEDSCHROEF,UNISTEEL,NM GROUP and etc.For many years, it has been in a leading position in the industry and was the first to pass the IS09001 quality management system certification. Backed by strong technical strength and talent advantages, Jungu strives to provide customers with cost-effective products and services.How to Satisfy Customers is our eternal pursuit.

Customers

We have built cooperation with many overseas clients in the word.

Certifications

Packaging & Shipping

FAQ

1. Q: Are you a manufacturer or a trade company?

A: We are a professional manufacturer of fastener mould with 10 years of experience in this industry.

2.Q: What is a cold forging die, and how does it function in the manufacturing process?

A:A cold forging die is a specialized tool used to shape metal at room temperature through high-pressure deformation. It functions by applying force to a metal blank, causing it to flow into the desired shape without heating the metal.

3.Q: What materials are typically used to manufacture cold forging dies, and why?

A:Cold forging dies are typically made from high-grade tool steels like H13 or SKD61, or carbide. These materials are chosen for their exceptional hardness, wear resistance, and toughness, which allow them to withstand the intense pressures involved in cold forging.

4.Q:What are the main advantages of using cold forging dies in production?

A:The main advantages include high-strength components, cost-effective mass production, superior surface finish, and reduced energy consumption compared to hot forging, making it environmentally friendly.

5.Q: What advantage do you have?

A:We mainly have three capabilities: Professional mould simulation development and design capability. High-precision and high stability mould manufacturing capability. Optimization capability for continuous improvement of mould life. 6.Q:Is it acceptable to visit your factory?

A:Welcome to our factory for a visit. Our factory is located in Taicang,shouzhou city,jiangsu province,China.The traffic is very convenient.

Thank you very much!

>> Taijia TEM-91 digital rebound hammer sclerometer digital schmidt concrete test hammer schmidt concrete test hammer

>> Cook, machine, household

>> 7.5 Tons Original Used Kobelco Sk75 Crawler Excavator Cheap Kobelco Sk55 Sk135

>> natural gas breakfast rice cereal puffing machine

>> LG Sigma Stainless Steel Ladder Step LG Ladder Flat Tooth 1200 Type 30 Degrees Sigma Elevator Accessories Escalator Parts

>> Verified Suppliers Support OEM Customization 8GB/16GB RAM 512GB 1tb SSD New Notebook Gaming Computer Laptops (15.6 inch-Intel Core I7-6567U/6650U)

>> Taijia British Pendulum Skid Tester / Pendulum Slip Tester for road pavement testing

>> Saudi Arabiahandle Paper Cup Making Machine Automatic Paper Hotel Cup Lids Making Machine

>> SRS-5600s Cartridge Seal Replace John Crane Type 5610 Pump Shaft Seal Parts

>> 15KW 25KW PVC Fabric Tents High Frequency Welding Machines For Tarpaulin

>> Scoop-Neck Long-Sleeves Appliques Ball Gown Cathedral Train Wedding Dress (Dream-100014)

>> Fire Fighting Hose Pipe Price/Fire Hose Price for Fire Hydrant Used

>> Manufacture Top Quality Dental Impression Material High Performance Yellow Mixing Tip

>> Desktop Computer I3 DDR3 4h Gen CPU HD SATA Industrial Fanless PC 1VGA 4USB3.0 RJ45 LAN Thin Client Computer

>> High Efficiency Large Potato Harvester with High-Performance Alloy Steel

>> Aluminum Extrusion/Industrial Aluminium Profiles Building Material

>> 2000 2500 bph bottled water production line mineral water filling bottling plant

>> Stylish Orange Two-Person Sofa for Cozy Home Living

>> Blank DIY Portable Painting Canvas

>> Kraussmaffei Kmd70 Twin Conical Screw Barrel for PVC Pipe

>> High Finish Precision Stability CNC Metal Lathe Esy106m

>> Best Dermal Collagen Cheek Jaw Cosmetic Hip DIP Sodium Hyaluronate Natural Jawline Under Eye Breast Face Nose Skin Booster Filler Hyaluronic Acid Lip Injections

>> 12W UV Disinfection Lamp/UV Filter for Water Purifier

>> Universal Vertical Metal Borehole Drilling Z3032X7p Radial Drilling Machine Tools Price

>> High Pressure Compact New Model Water Heater Flat Plate Collector Solar Water Heater for Commercial Hot Heater System Price

>> Outdoor Wall Street Lamp Waterproof Floodlight Garden Gymnasium Projection LED Light

>> Pet Grooming Table for Competition Foldable Aluminum Table with Non Slip Surface

>> Agricultural Machine Walking Tractor Power Tiller 8-18HP Rotavator

>> Hardware Accessories Zinc Alloy Plastic 9.3G Connector Fasteners Suction Bracket

>> Ultrasonic Welding Machine Generator System Digital Automatic Tracking 20kHz 2000W Customized Horn