New Djw-901 Water Jet Loom Polyester Textile Weaving Machinery in Surat

| US$5,800.00-23,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

DJW-901 Water Jet Jacquard Loom

Computerized

Computerized

Precision

High Precision

Certification

CE, ISO9001: 2000, CQC

Warranty

1year

Customized

Customized

Condition

New

After-sales Service

Yes

Feeler

Photoelectric, Optical

Creel Stand

Floor Mounted, Horizontal Stand

Speed

600-1400rpm

Weft Density

5-60thread/M

Power

2.2-4.5kw

Beam Flange Diameter

800mm 1000mm

Transport Package

Waterproof, Plastic Protection Package

Specification

1700mm-3600mm

Trademark

DAPENG

Origin

China

HS Code

8446304000

Production Capacity

12000sets/Year

Packaging & Delivery

Package Size

310.00cm * 150.00cm * 125.00cm

Package Gross Weight

1500.000kg

Product Description

| Model NO. | DJW-901 Water Jet Jacquard Loom | Condition | New | |

| After-sales Service | Spare Parts Supply and Technical Support | Shedding Type | Plain, Cam, Dobby | |

| Reed Width | 1700mm-3600mm | Bearing | NACHI,NSK | |

| Weft Insertion Rate | 2280m/Min | Customized | Customized | |

| Trademark | DAPENG | Origin | China | |

| HS Code | 8446304000 | Production Capacity | 12000Sets/year |

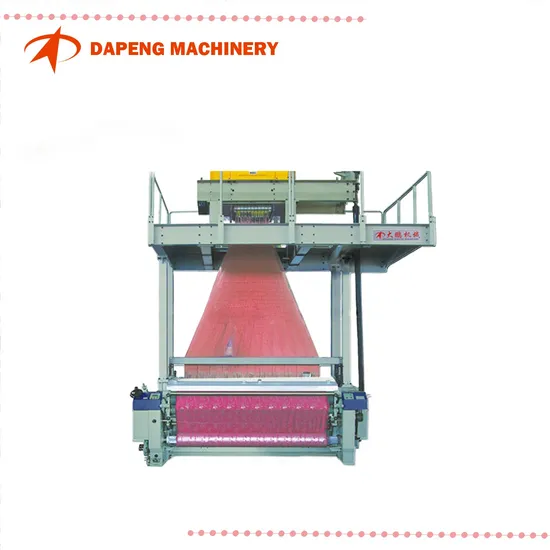

DJW-901 Water Jet Jacquard Loom

Feature

The electronic jacquard machine adopts computer information processing technology to transform the pattern information of jacquard fabrics into the control information of the jacquard machine, and the electromagnetic needle selection mechanism of the jacquard machine is controlled by the computer program. The control system is composed of special microcomputer controller and liquid crystal display, which can display product code, output, time and other parameters, easy to operate, and can ensure long-term reliable operation. Needle selection is both simple and reliable, changing the traditional way of needle lifting, so that the volume of the needle selector is greatly reduced, with a high degree of electronization, fewer mechanical moving parts, and selecting needles in the lowest position to ensure the accuracy of needle selection.

| Reed Space | 1700mm-3600mm | Customized | Customized |

| Weft Insertion Rate | 2280m/Min | Speed | 600rpm-1400rpm |

| The Number of Heald Frame | 2, 4, 6, 8 Pieces, Cam Shedding 10 Pieces Utmost | Weft Density | 5-60 Thread/M |

| Beating up Method | Four-Linkage Beating up Shaft | Power | 2.2kw-4.5kw |

| Feeler | Photoelectric, Optical | The Effective Width | 0-500mm(Standard) 0-700mm(Optional) |

| Creel Stand | Floor Mounted, Horizontal Stand. | Drive | Push Button Switches for Start, Stop |

| Suction | Mechanical, Electronic | Temple | Top Mounted |

| Let off | electronic let off | Weft selection | Two color, four color, six color and continuous expansion function |

| beating up | "U" shaped beating up shaft | take up | electronic take up |

| Yard end treatment | Discarded take-up 2pcs drum-type | Selvage | Planetary gear type Selvage device |

| lubrication | Main transmission part oil bath type, manual centralized oil supply | Weft cutting | Mechanical weft cutting device |

| Weaving range | spun:Ne100~Ne2.5 | automation | inverter to adjust speed. |

Water jet loom is an efficient weaving equipment, mainly evaluated in the textile industry, with a wide range of application fields and specific scope of application. The following are the application directions of water jet looms:

Textile industry: Produces various fabrics, such as cotton fabrics, silk fabrics, linen fabrics, etc. It is suitable for the production of key filament chemical fiber fabrics with smooth surface. It is favored for its fast weaving speed and high unit output.

Garment Industry: Used to make shirts, trousers, trousers and other clothing products.

Home industry: Used to make bedding, curtains and other household items.

Orientation

Qingdao Dapeng Machinery Co., Ltd. has advanced processing equipment and excellent technical personnel.

Responsibility

The company in line with the "meet the user low-cost weaving high quality fabrics needs" as the goal, adhering to the "continuous technological innovation, quality and steadily improve the service excellence" business philosophy, for the customer to create exquisite products, dedication and perfect service.

raw materials

The main subassembly and raw materials are all supplied by large companies. Key parts are research and developed by our own staff. Professional assembly line work and strict quality test system can ensure your high quality requirement.

Packing

Package Size

569.00c* 213.00cm * 218.00cm

Package Gross Weight

10000.000kg

Shipping

Delivery Port: Qingdao port

1.Premium Certified Supplier

Raw material quality control

Certificated supply of important components

2.Production management system

Processing workshop-Superfinishing the key parts.

Electrophoretic coating workshop-Anti-corrosion treatment of the machine

Assembly workshop - Shuttle-less loom pulsating production line

3.Package system

Dapeng assembled the shedding and body before delivery, and then the loom can be adjusted and used directly after arriving at the customer site.

Separate Package. The shedding is separated from the body before shipment, and assembled after arriving at the customer's site.

4.After-sales service system

Dapeng has a perfect after-sales service system. We has established a professional technical service team to provide comprehensive after-sales service and technical solutions for customers. Dapeng will make a return visit to every customer to guide customers how to use and maintain the machine. For customers who have problems during use, we will conduct one-on-one phone calls or video guidance at first.

5.Quality control management system

Dapeng implements strict traceable quality control over the entire production process from raw material selection, parts processing, spraying process to final assembly. Conduct pre-job operation training and post-job operation control for workshop workers to ensure that the operation conforms to the production process. In addition, Dapeng adopts advanced calibration and testing equipment to ensure that the pass rate of each process is above 98%. Dapeng provides customers with a one-year warranty. If there is any quality problem with the loom during the warranty period, Dapeng will replace the parts for free.

6. Storage management system

Automatic stereoscopic warehouse-Warehousing of materials. Finished Products Warehouse-Loom storage.

Dapeng has a perfect after-sales service system. We has established a professional technical service team to provide comprehensive after-sales service and technical solutions for customers. Dapeng will make a return visit to every customer to guide customers how to use and maintain the machine. For customers who have problems during use, we will conduct.

Q: How's the after-sale service?

A: We offer engineers available to service overseas under merchandiser's supervision and translation.

Q: Are you available for on-the-spot invitation?

A: We do welcome our new and old friends come here to have a visitation. Besides, we would send you our exposition and relative information to promote a face-to-face meeting if you'd like to.

Q: Is the price offered changeable?

A: We offer reasonable price for every client, and the price is changeable according to purchasing amount.

Q: How about the quality?

A: The main subassembly and raw materials are all supplied by large companies. Key parts are research and developed by our own staff. Professional assembly line work and strict quality test system can ensure your high quality requirement.

Q: Are you a manufacturer or Trade Company?

A: We are a professional manufacturer holding our own International Trade Department, for that we can better understand customer's needs and offer a reasonable price.

Q: Product /Quality Guarantee and After Sale Service?

A: 1 year warranty for the International standard. We are work online 24 hours. If you have any questions about our machine you can contact us.

Q: One-stop Service:

A: We have R&D department including more than 20 engineers which are improving and enlarging our supply range.

>> Showstopper Clear Crystal Spotlight Trophy Award

>> Automatic drinking pure water/milk/juice pouch sachet filling packing machine price

>> Heavy Construction Machinery Hydraulic Crawler Excavator Ze245 for Sale

>> Desktop Sff 7.5L Computer Case, Tfx Power Supply Supported, PC Case

>> 100% Original Model 2 3 4 Buttons Remote Replacement Car Key Blank Car Key Shell for Toyota Corolla Camry Matrix Yaris RAV4 Key Toy43

>> Hot Press Turbo Segment Diamond Cutting Saw Blade for Tile Ceramic Concrete

>> Insulated Fire Rated Aluminum Material Clip-in Ceiling Acoustic Sound-Absorption Ceiling

>> CNC Inclined Bed Lathe Machine Bck520 High Quality CNC Lathe Machine

>> Cosmetic Soft Tube Heading Machine Soft Tube Injection Heading Machine Plastic Soft Tube Heading Injection Moulding Machine

>> High Quality 2ton 3 Ton 4tons Customized Railway Crawler Digger Bagger Excavator

>> Hot sale bamboo chips weaving machine bamboo mat knitting machine

>> stainless steel double edge adjustable aluminum shavings razor

>> Custom PU Diary Book A4 Leather Monthly Planner 2024 Daily Agenda Notebook

>> Ple Cement Mixing Drum, Concrete Mixing Drum, Concrete Mixing Drum Accessories

>> Scanning Metal Locator/Concrete Scanner

>> 4 5 6mm Clear,Tinted Frameless Round Rectangle Oval Shape Clear Tinted Edge Beveled Round Edge Aluminum Mirror Silver Mirror for Bathroom,Living Room Decorative

>> ISO Ce SGS Approved 3-5t/H Poultry Animal Feed Making Machine

>> Factory Supply AC Plug Vertical Injection Molding Machine Manufacturer

>> OEM cast iron eco-friendly enamel pot colorful cooking ware

>> High Speed T-Shirt Embroidery Machine 8 Heads

>> Ym Aw70 Rubber Track 500*Aw90*51 for Harvester Machines Parts

>> DS200TBQDG1AFF

>> Candid High Quality Barbed Wire Making Machine with Good Price

>> Hydraulic Drive High Cost-Effective Aluminum Gravity Casting Machine Foundry Aluminum Equipment

>> Inflatable Human Soccer Billiards Balls Table

>> CP6266L Torno Paralelo Universal Heavy Duty Metal Turning Lathe Milling Machine

>> 0-1vrms to 0-5V Signal Transmitter with 3kv Isolation

>> Cheese Ball Expanded Corn Snacks Food Machine

>> Pig Farm Equipment 201# Stainless Steel Water Drinking Nipple

>> Steel Cable Conveyor Belt Repair Rubber Cover Strip with Fabric Layer