Empty Composite LPG Gas Cylinder Making Machine Composite Cylinder Production Line

| US$3,500,000.00-5,000,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HLT

Function

Heat Pressure Vessel

Application

Gas

Material

Other

Pressure

10.0MPa≤p<100.0MPa

Storage Medium

Other

Pressure Level

Medium Pressure (1.6MPa≤p<10.0MPa)

Condition

New

Length of Spool

280mm

Single Tension Range

5n-100n

Tension Tolerance

Above 10n +/- 5%

Spool Inner Diameter

76mm

Single Tension Tolerance

up to 10n +/- 0.5n

Spool Weight

15kg

After-Sales Service Provided

Engineers

Core Components

PLC, Engine

Weight (Kg)

1000

Transport Package

Standard Package

Specification

Max. spool outer diameter: 260mm

Trademark

HLT

Origin

Jiangsu, China

Production Capacity

400sets/Year

Product Description

Empty Composite LPG Gas Cylinder Making Machine Composite Cylinder Production LineProduct Description

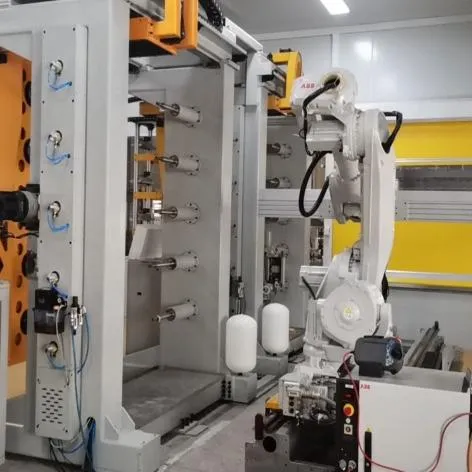

Detailed Photos Our standard offer includes: 1. Liner blow molding machine. 2. Liner loading stations: Automatic handling of the liners between the liner loading station, filament winding machine and the curing oven. 3. Filament winding machines with very fast winding times. 4. State of the art automatic cut & restart system for the fibers (patented). 5. Quick-clean resin bath with automatic resin mixing system. 6. Fiber creel with different types of tension control and fiber broken detection. 7. Efficient curing oven with air-exchange control. 8. Vessel testing equipment. 9. Surface treatment equipment and other auxiliary equipment. 10. Top level control system for supervision and quality control. All of these units are controlled and monitored by our top level control system, which allows control of the complete manufacturing process from each location. Each of these units can also operate as an independent station.In cooperation with our partners we can offer complete turnkey solutions for our end customers. This means that we can deliver blow molding machines, necessary testing equipment, stations for assembling, surface treatment equipment and other auxiliary equipment. Part of our supply is development of the cylinder, which consists of design of the liner and connections, the design of the composite and testing, and finally we can offer certification of the high pressure cylinders under required standards . We meet requirements for even higher automation of the manufacturing process, keeping human intervention at lowest possible level, while increasing throughput and lowering cost per cylinder. Complete project realization is managed and coordinated from one place, thus giving the customer more time to concentrate on his marketing and sales activities. Contact us to find out how we can realize your plans for sales of LPG, CNG, hydrogen and other high pressure cylinders. According to the production requirements of different composite gas cylinders, we developed an automatic flexible gas cylinder production line which realized automatic and intelligent manufacturing of LPG cylinders, brake cylinders, CNG cylinders, breathing cylinders, and vehicle-mounted hydrogen storage cylinders. Each production line has an annual production capacity of 300,000 composite pressure vessels, The production plant area of 2000 square meters, and power consumption of 500 kilowatts. It can complete the processes of inner tank forming, interface processing, composite material winding, resin preparation, curing and molding, etc. It can also carry out fully automatic production testing of gas cylinders, which truly realizes high-efficiency and high-quality mass production of composite gas cylinders. We have independently developed a full set of gas cylinder testing equipment such as cycle charge/discharge tester, negative pressure vacuum tester, drop tester, bursting tester, etc. according to the requirements of composite container testing. We realize gas cylinder pressure test, gas tightness test, bursting test, normal temperature pressure cycle test, accelerated stress fracture test, impact test, crack tolerance test, fire resistance test, valve seat strength test and other tests. Product Parameters Liner Shaping Function: As the plastic liner will deform after being taken out of the blow molding machine, it needs to be shaped to ensure the stability and consistency of the geometry of the liner. Boss/Neck Insert Function: insert the boss seat into the bottle of the liner, and at here the boss and seat is heated to weld the boss with the liner. Tightness and strength testing

Function: Tightness and strength testing of welded seat and liner Cylinder Hanger

Function: The equipment can be rotated to realize continuous operation. Shaft Assembly Function: 1. The connecting rod is automatically connected, 2. At the same time, the flame/plasma surface treatment of the liner is realized at this station, thereby improving the bonding performance of the plastic liner and the resin. Cylinder Hanger Function:LPG cylinder liner buffer and transfer Liner Pretreatment Function: The blow molding machine blows the liner, and the robot takes the liner out of the blow molding machine, puts it on the cooling machine to cool the liner to maintain the shape of the liner , and then the robot takes out the liner and measure the weighs of the liner, and then the metal boss is welded on to the liner, Then the surface treatment of the liner is carried out, and the robot takes out the liner and places it on the turntable. Winding Process Function: The multi-station winding machine realizes the simultaneous winding of 5 gas cylinders. The robot automatically takes the liner and automatically puts it on the winding machine. the fiber yarn is lead to the line and being lapped and cut down automatically. After the winding of fiber is completed, the robot puts the composites cylinders on the automatic conveyor,which is connected to the curing oven. Cylinder Curing Function: The circulating curing furnace completes the heating and curing of the cylinders, and the cylinders enters and exits the curing furnace through an automatic conveyor chain. The curing furnace can accommodate 500 cylinders simultaneously. Water Pressure Test Function: The LPG cylinder is first tested for water pressure. The water pressure detection equipment first injects water into the LPG cylinder and Pressurize the water inside the cylinder,Record the measurement results, then the LPG cylinder is turned 180 degree to releases the pressure,and discharge the water. After that the valve is installed, and the lpg cylinder is sinked into the water to check if the cylinder is leaking, and then the air is blown to the cylinder to make it dry. Company

FAQ

How to ensure your cylinders' quality?

A: Our LPG cylinder factory possesses ISO9001 certificate, and we have been in this field more than 50 years.

Our products have been sold almost all over the world, especially with the mature market.

About the brand name of the products?

A: In general, We use our own brand, if you have requested, OEM is also available.

About the sample?

In our acceptable range, we can offer a sample by charging freight. We will return the fee after you make an order.

About payment term and delivery time?

A: payment term: 30% for TT, 70% TT before delivery

we can delivery 1*40HQ containers and below within 10 days after deposit payment.

>> Athletic Fitness Jogging Shorts Wholesale Polyester Mens Activewear Quick Dry Workout Gym Sports Running Shorts

>> Durable PVC Boards for Pig Equipment and Livestock Housing

>> Gas Water Pipeline 12mm White PTFE Teflon Tape Pipe Plumbing Seal Tape for Shower Head Leaks

>> Fire Alarm Security Ta-Fiv Siren System

>> Espresso Stainless Steel Coffee Tamper with Three Angled Slopes

>> Large Tonnes Car Parking Platform Lift Car Parking Lift Price High Quality Basement Scissor Car Parking Lift Double-Deck Scissor Car Parking Lift

>> Nylon vacuum packaging bag meat vegetables vacuum bags Heat seal Composite vacuum bag

>> 1ml Luer Lock Oil Glass Syringe with Plunger Rod

>> Concrete Rebar Locator Scanner Locate steel bar tube in reinforced concrete

>> Good Quality Servo Power 90mm Big Screw Barrel Special Bottled Drinking Water Pet Preform Jar Tube Injection Molding Machine

>> LCP20h-H Hose Type Concrete Pump for Spraying Concrete

>> N730 24FT /7.4m Fully Welded Enclosed Cabin Aluminum Alloy Commercial Fishing Boat

>> New Design 1500W Laser Cutting Machine for Steel Metal for Promotion

>> High Quality Factory Stock Electric Adjustable Automatic Emergency Evacuation Stair Chair with Rechargeable Battery

>> Beisijie Height Adjustable Stable Support Custom Gaming Table

>> C43AMG 4matic C300 C350E W205 Aluminium Radiator Water Cooler 0995002203

>> Taiwan Rice Roll/ Bread/ Cake /Biscuits Horizontal Pillow Packaging Machine For Bakeshop

>> Air Shipping Sea Shipping Container Shipping Logistics Shipping FCL/LCL Agent From China to Africa Europe Door to Door Shipping

>> Multiple Colour Unisex Open Face Motorbike Helmet DOT Certified Racing Helmets

>> Forming Fabric Triple Layer, 2.5 Layer Single Layer for Special Paper and Graphical Paper

>> Precision Double Spindle CNC Lathe Machine Ety208msy with Servo Drive System

>> TV Antenna Power Supply Adapter 12V 100mA, for Poland Market

>> Double Side Hanging LCD Wall Elevator Display Digital Signage

>> Polished Aluminium Water Tank/Air Tank

>> Mechanical Concrete Test Hammer Silver Rebound Hammer price

>> Agricultural Factory OEM/ODM Blade Disc Power Harrow Rakes Shift Gear Cultivator Rotary Tiller Gearbox

>> Android Wearable Smart Watch (SW-4G Positioning Health Monitoring Geofence Alarm)

>> single-row potato harvester machine for sale potato digger

>> Modern front mahogany solid wood door exterior door for villa

>> Electric Barbecue Grill and Tandoor