Factory Directly Sale Psd Series High Speed Plate Drilling Machine

Basic Info.

Model NO.

PSD cnc drilling machine

Structure

Bench Drilling Machine

Layout

Horizontal

Controlling Mode

CNC

Number of Shaft

1

Hole Diameter

50mm/63mm

Automatic Grade

Automatic

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Max Stack Thickness

200mm

Function

Drilling Machining

Machine Type

Drilling Equipment

Workpiece Size

2000*1600*200

Tapping Dia.

M30

Servo Motor Power

2*2kw

Spindle Motor Power

11/15/22/25

Maxium Stoke

400mm

Transport Package

Packages

Specification

4*2.7*2.5m

Trademark

RAINTECH

Origin

China

HS Code

8462490000

Production Capacity

100 Sets/Month

Packaging & Delivery

Package Size

50.00cm * 60.00cm * 70.00cm

Package Gross Weight

1000.000kg

Product Description

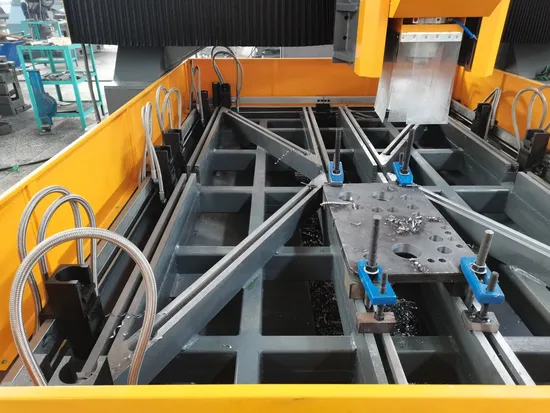

Factory Directly Sale PSD Series High Speed plate drilling machineProduct Description

Product Parameters

| Model | PSD2016 | PSD2020 | PSD3016 | PSD4030 | |

| Workpiece size | LengthxWidth(mm) | 2000*1600 | 2000*2000 | 3000*1600 | 4000*3000 |

| Max stack Thickness(mm) | 200 | ||||

| Sliding CNC power head | Spindle taper hole | BT50 | |||

| Drilling diameter (mm) | Ф50 (Optional Ф63) | ||||

| Tapping diameter (mm) | M30 | ||||

| Spindle speed (rpm) | 30-3000(frequency conversion stepless) | ||||

| Spindle motor power (KW) | 11/15/22/25 | ||||

| Torque (n<600r/min) | 190/240/360Nm | ||||

| Spindle surface to worktable distance (mm) | 230-630 | ||||

| Longitudinal movement of gantry(Xaxis) | Maximum stroke (mm) | PSD2016:2000 PSD2020:2000 PSD3016:3000 PSD4030:4000 | |||

| Servo motor power (KW) | 2*2 | ||||

| Maximum moving speed (m/min) | 10 | ||||

| Power head vertical movement (Zaxis) | Maximum moving speed(m/min) | 8 | |||

| Servo motor power (KW) | 2 | ||||

| Maximum stroke (mm) | 400 | ||||

Product Application

PSD Series machine is mainly used for drilling and milling of connection plates and anchor plates in steel structures, iron towers, bridges, machining and other industries. Drilling and milling of tube sheets, baffles and flanges in pan frying, petrochemical, pressure vessel and other industries; it can drill through holes, blind holes, stepped holes, hole end chamfering and light milling.

Feedback from our customers

certificate and patents

Company Profile

Shandong Raintech Sans Technology Co., Ltd. is a high-tech enterprise that integrates product development, designing, production, sales and service in metal roll forming and coils processing industry.

Our Products :including various kind of metal profile roll forming machines, such as solar strut panel roll forming machine, automobile bumper roll forming machine, green house structure roll forming machine, truck beam roll forming machine, highway crash barrier roll forming machine, etc. Tube mills and coils slitting line, cut to length line

Our History: Our factory established in 2008 by one of our company founder Mr. Xu, who was as leader of china roll forming technology research team in SINOMRCH more than 10 years. Since 2008, we started design , engineering and manufacturing of all kinds of roll forming lines, including many difficult lines at same level of world advance technology. At the same time, we also design and produce cut to length line, slitting line and tube mills on the high level quality in china.

Our Technical Strength : We have advance and earliest technology on metal forming and processing . Since 2008, have been succeed in many difficult lines which require high precision, high speed, and big strength used in railway, highway, metro system, electrode plate,solar structure , automobile etc. We have our special design on machine structure and rollers design, punching and cutting design to assure the speed , accuracy and life of machine. We are coincidental for bigger challenge in future on keep advanced in this field

Our Team :

We own an professional oversea marketing team leads by our CEO Ms. Rain

Main technical support team lead by Mr.Xu and after-sales service team with engineers.

We also have local service team in some countries all over the world

Our Service : We provide complete process on quality control, machine trial , TUV, SGS BV inspection before dispatch. And provide free installation and training at customer site. And moreover, we have our own professional local service team in some countries such as India, Egypt , Italy etc.

Our Goal : we have been devoted to the more advance technology in metal roll forming and processing field , trying our best to be the first level of roll forming technology in the world famous manufacture list

package payment and shipping

FAQ

1. What's your advantage ?

A: We assure each machine dispatched from our factory a long-life usage with easy operation and humane design.We consider help our customer to hence the production efficiency and save your human power as our aim.

2. How l believe you?

A: Welcome to visit us to check our plant and ability, the payment method can be chosen and the third party inspection through ****** is available.

3. What about the warranty of your products?

A: We provide 12 months warranty since the machine arrived at customer site , free charge of spare parts and oline maintenance service.

4. Where are you? Can l visit you?

A: our factory located in Shandong province, china, welcome to visit us at any time.

5. How about the delivery time?

A: For standard model, the delivery usually 25 days since the advance payment receipt. For the customized products, the delivery time will follow our agreement with customer.We never receive any complain from our customers for the delivery time.

6. What kind of payment does your company support?

A: TT,100% LIC at sight,Cash, Western Union are accepted. If you have other payment terms, welcome discuss with us.

>> Professional High Precision CNC Lathe with Inclined Bed

>> Seamless Clip Hair Extension 100% Brazilian Virgin Remy Human Hair

>> Plastic Door and Window Horizontal Four-Corner Welding Machine Innovative UPVC Profile Welding Machine

>> Men′s Autumn and Winter Trendy Casual Comfortable Cotton Athletic Pants

>> Baby Kids′ Scooters Scooter for Kids Kick 3 Wheel Germany Kid Children 2022 with Seat

>> Red Chili Pepper Powder, Paprika Powder From China

>> Big double suction pump impeller

>> 2022 new design Wholesale Commercial Gym Fitness or Home Use Arm Wrestling Machine

>> 500W LED Hybird/LED 3in1 Moving Head LED Light

>> Automation Full-Electrical System CNC Mini Press Brake for Sale

>> Customized Interlocking Carpet Tiles Protector Entrance Door Puzzle Mat Floor Mat for Home and Office Floor Decoration

>> 5pcs Bamboo kitchen tools/ Wholesale Bamboo cooking utensil set from China

>> Rusty Outdoor Corten Steel Rectangular Metal Decoration Garden Light Cover

>> General Mobile Adjustable Stainless Steel Mobile Hydraulic C Arm Surgical Operating Table for Ot Room

>> Non-Surgical rf fat dissolving machine Id RF Monopolar Fat Reduction Body Contouring Sculpting Machine

>> Clw Brand 70m3 LPG Storage Tank ASME GB150 Good Price 20mt LPG Tank 50m3 LPG Bullet Storage Tank

>> Waist Wringgling Plate Fitness Twist Disk Large Twister Device Foot Massager

>> 100L 200L 500L 1000L Stainless Steel Jacketed Electric Heated Mixing Tank

>> Onpow USB Connector/USB 3.0/ Panel Mount 22mm/Metal Plug/Chargers/Type C

>> Park Garden Natural Stone Hand Carved Large Marble Flowerpot

>> Hot Sale Good Quality Essential Bags Contents First Aid Kit

>> 2024 New Custom Animals Sensory Touch Non-Slip Design Textured Sensory Mat Mini Mats for Kids

>> Famou Poultry Equipment Durable Design Semi-Automatic Feed Distribution System

>> Electronic Pulse Infrared Heating Vibrating Foot Leg Massager

>> Popular Design Sanitaryware Cupc Undercounter Sink Bathroom Oval Shape Undercounter Ceramic Basin Wash Basin Wall Hung Basin Undermount Sink

>> Cookie Mixing Machine Dough Mixer Vertical Dough Mixing High Speed Dough Mixer

>> Professional Wood Drilling Machine Set with Varying Bits

>> 4m3 Mobile Concrete Mixer Truck for Sale

>> hay chaff straw grass cutting machine/ corn stick cutter /chaff cutter

>> 5m3 16bar Mini Cryogenic Liquid Nitrogen Storage Tank Microbulk Cylinder for Gas Industry