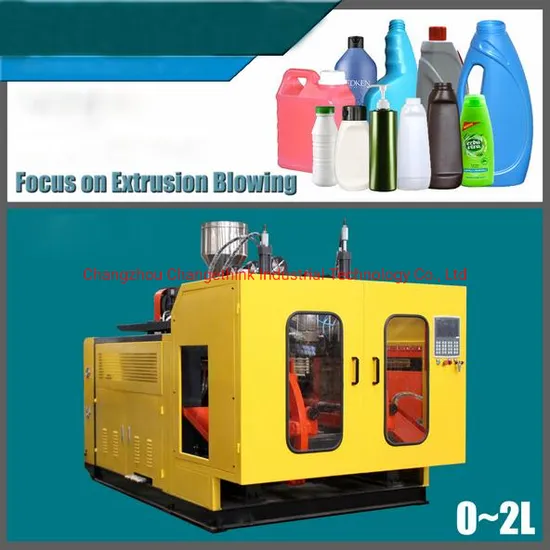

Lty55D-2 Extrusion Blowing Molding Machine for HDPE Bottle

| US$26,000.00 | 1 SET (MOQ) |

Basic Info.

Model NO.

LTY55D-2

Raw Material

HDPE

Making Method of Parison

Extrusion-Blow Molding

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008, QS, GMP

After-sales Service

Special After-Sales Service Man

Transport Package

Wrap Film Packing to Load Into Container

Specification

pp and pe bottle blowing

Trademark

LOYALTY

Origin

China

HS Code

8477301000

Production Capacity

10sets/Month

Product Description

CHANGZHOU LOYALTY INDUSTRY CO.,LIMITED is specialized in Extrusion Blow Molding field. We provide blow molding machines, hollow moulds, auxiliary machines, special processing devices and project service for your production plans.| 1 | LTY55D-2 is double station double head EBM machine specially for 0~1L products. |

| 2 | The output for 500ml round bottle is 600 BPH, the daily output is about 14400 bottles. |

| 3 | High efficiency extrusion system is generally suitable for LDPE, HDPE and PP. |

| 4 | Adopt nether bent arm clamping structure guided with linear rails for double direction. |

| 5 | With two pneumatic cylinder for head lifting in balance, clean & easy for maintenance. |

| 6 | Optimized hydraulic system & mechanical shuttle cylinder for platen moving stability. |

| 7 | Lubrication system, product clamping boards and scraps slide channels are included. |

| COMPONENTS | BRAND | ORIGIN |

| PLC | MITSUBISHI | JAPAN |

| TEMPERATURE CONTROL MODELS | HONGGE | TAIWAN |

| COLORFUL TOUCH SCREEN | WEINVIEW | TAIWAN |

| CONTRACTOR | SCHNEIDER | FRANCE/CHINA |

| AIR SWITCH | SCHNEIDER | FRANCE/CHINA |

| MID RELAY | OMRON | JAPAN |

| PROXIMITY SWITCH | RIKO | TAIWAN |

| INVERTER | DELTA | TAIWAN |

| OIL FILTER | DONGFANG | CHINA |

| OIL TUBE & JOINT | PACKER | U.S.A. |

| SEAL PARTS | DZ | TAIWAN |

| HYDRAULIC PUMP | HYTEK | TAIWAN |

| HYDRAULIC VALVE | HYTEK | TAIWAN |

| PNEUMATIC VALVE & CYLINDER | AIRTAC | TAIWAN |

| COMPRESSED AIR FILTER | AIRTAC | TAIWAN |

| LINEAR GUIDE RAILS | HIWIN | TAIWAN |

| HARD GEAR BOX | HAOKE | CHINA |

| HYDRAULIC PUMP MOTOR | SIEMENS BEIDE | CHINA |

| EXTRUSION MOTOR | SIEMENS BEIDE | CHINA |

| SPECIFICATIOIN | /PARAMETER | ||||

| Machine Model | Double Station Double Head | ||||

| Max Product Volume | 1000 ML | ||||

| Dry Cycle Time | 4.5 Second | ||||

| Pre-heating Time | 1.5~2.0 Hours | ||||

| Machine Weight | 4.5 Tons | ||||

| Machine Size | 3.2*2.1*2.3 m | ||||

| /EXTRUSION UNIT | |||||

| Screw Diameter | 55 mm | ||||

| Length/Diameter Ratio | 24:1 | ||||

| Heating Zone No. | 3 | ||||

| Heating Power | 11.6 KW | ||||

| Cooling Fan No. | 3 | ||||

| Fan Power | 0.15 KW*3 | ||||

| Extrusion Motor Power | 15 KW | ||||

| Plasticizing Capacity | 65 Kg | ||||

| /CLAMPING UNIT | |||||

| Clamping Force | 56 KN | ||||

| Platen Size | 290*360 mm | ||||

| Platen Moving Distance | 375 mm | ||||

| Platen Opening Stroke | 130-380 mm | ||||

| Max Mould Size | 310*360 mm | ||||

| Mould Thickness | 135-230 mm | ||||

| /HEAD UNIT | |||||

| Head Type | Continuous Extrusion Head | ||||

| Head No. | 1 | 2 | 3 | 4 | |

| Central Distance/mm | - | 130 | 90 | 75 | |

| Max Die Diameter/mm | 110 | 60 | 35 | 25 | |

| Heating Zone No. | 2 | 3 | 4 | 5 | |

| Heating Power/KW | 4.2 | 3.3 | 4.2 | 6 | |

| /ENERGY CONSUMPTION | |||||

| Extrusion Motor Power | 15 KW | ||||

| Oil Pump Motor Power | 5.5 KW | ||||

| Extrusion Heating Power | 11.6 KW | ||||

| Head Heating Power | 4.2 KW | ||||

| Cooling Fan Power | 0.45 KW | ||||

| Total Power | 36.68 KW | ||||

| Average Energy Consumption | 21.5 KW | ||||

| /REFERENCE | |||||

| Cold Water Needed | 0.3 Mpa | 3500 L/h | |||

| Compressed Air Needed | 0.6 Mpa | 0.6 M3/min | |||

| Installation Capacity | 100 Amp, 3*25 m+ 1*16 m | ||||

| Loading Reference | 20' GP*1 | ||||

>> No Flicker 8-12*2W Isolation Built-in Driver Indoor Lighting Power Input AC85-264V Output 24-42V600mA Constant Current LED Driver

>> NFRC double glazed aluminium awning window top fixed windows

>> Auto Cooling Parts Brand New Engine Coolant Thermostat for CLA Class W117 2822030075

>> Helium Leak Gas Detector Gas Analyzer Meter Helium Measurement Sensor Gas Safety Device

>> Customize Automatic Extrusion Blow Moulding Machine for Hand Sanitizer Bottles

>> Almond Oil Press Machine Olive Oil Press Small Cocoa Butter Hydraulic Oil Press Machine Peanut Oil Press

>> High Aluminum Bricks for Bottom of Mannheim Sop Furnace

>> High Performance Rubber Processing Machinery Lab Rubber Open Two Roll Mixing Mill

>> Customize Saw Chain High Quality EPA/Carb Certificated Fuel Hose for Garden Machinery

>> High Precision OEM Stainless Steel Filter Expanded Metal Mesh

>> High Precision Deep Drawing Die for Metal Forming Applications

>> Natural Juice Hot Washing Filling Capping Machines Water and Juice Production Line The Complete Line of Juice Production

>> Kitchenware Food Processor Meat Grinder Stand Mixer Chopper Blender Food Machine Mincer Bean Grinder Sausage Suffer Electric Meat Grinder

>> Taijia Wall Crack Width Measurement Microscope Instrument test digital crack width gauge

>> High Quality Kids Bike 12"14"16"18" Children Bicycles Factory Cheap Hot Sale Bike

>> Automatic Flip Cover Mechanical Cabin Bluetooth Headphones

>> Sale Mobile Mini stone rock jaw crusher machine on sale jaw crusher machine for the stone small diesel engine jaw crusher

>> Office Building Scale Model Maker (JW-41)

>> Commercial Portable Sawmill Mobile Band Saw Machines with Wheel

>> bbq expanded metal mesh aluminum expanded metal mesh panels

>> Dalian Iron Casting Grey Nodular Cast Iron

>> 400L Hot Products Kitchen Appliance Double Door Fridge Double Door Display Fridge

>> China Oto Pulley Type Wire Drawing Machine

>> 8L Class B Tabletop Steam Autoclave for Sterilization with LCD

>> White with Black Letters Welcome Wall Hanging Porch Sign

>> For paper wood chips plastic compost soil topsoil mobile trommel screen

>> Fashion Outdoor Backpack Black Casual Backpack Sport Hiking Backpack for Camping

>> ERW Steel Pipe and Tube Carbon Steel Straight Seam Welded Pipe and Tube High Frequency Pipe Making Machine Pipe Mill Machine Tube Mill

>> Drum Lubricant Bar for Ricoh MP C6000

>> Custom Sublimation Printed Logo Polyester Waterproof Fitted Stretch Spandex Table Cover Table Cloths Fitted Table Cover