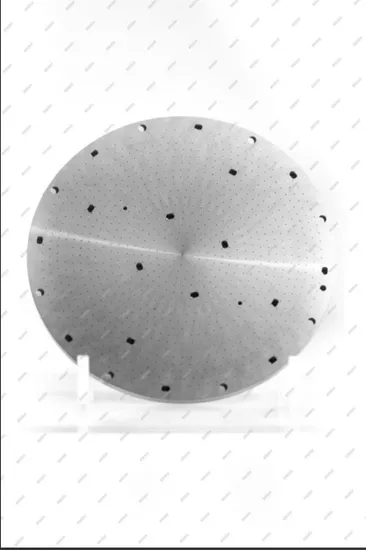

CVD Sic Shower Head Semiconductor Etching Equipment

| US$500.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

CVD SIC COATING

Substrate

Isostatic Graphite

Coating

β-Sic

Coating Thickness

100-150μm

Flexural Strength

≥50MPa

Material Consistency

Over 95%

Material Purity

99.9995%

Transport Package

Wooden Box

Specification

Customizable

Trademark

DZ

Origin

China

Production Capacity

80000PCS/Year

Product Description

Company ProfileHunan Dezhi New Material Co., Ltd. is a high-tech enterprise focusing on the research, development, production and sales of high-end materials such as carbon-based and ceramics. Dezhi is the first company to achieve mass production of Solid SiC etching components for semiconductors in China, and has high-end technology, equipment and a high-level R&D team. The company currently has about 300+ employees, of which R&D personnel account for 20%. Our R&D capabilities and product quality are unanimously recognized by the industry and main products include CVD@SiC coatings, Solid SiC, Sin@SiC-SiC, CVD@TaC coatings and other series of products, which are widely used in LED optoelectronics, integrated circuits, third-generation semiconductors and other fields.

Product Description

Dezhi advanced material products cover carbon-based, ceramic and other high-end materials, used in all aspects of semiconductor chip manufacturing, such as single crystal growth, epitaxy, etching, diffusion, CVD, PVD, etc.

Product performance:

| High Temperature Resistance | High Pressure Resistance | Wear Resistance | High Service Life | Corrosion Resistance | High Purity |

Materials and Characteristics

| •Substrate: Sintered SiC (thickness>0.5mm) | •Coating: β-SiC (thickness<300μm) |

Application Scenarios Wafer Fabrication

| • Epitaxial | • Diffusion |

Implementation Technology

| • Precision Machining (Graphite) | • Low Pressure Chemical Vapor Deposition |

Performance Requirements

| • High density | • Strong combination | • High purity |

| • High thermal conductivity | • Corrosion resistance | • Resistance to cracking |

Application Areas

| • LED Photoelectric | • Integrated circuits | • Third-generation semiconductors |

Product Parameters

Product Range | Materials and properties | Application Scenario | Implementation Technology | Performance requirements |

| CVD@SiC coating series | Substrate: Isostatic graphite (Thickness 1~20 mm) Coating: β-SiC (Thickness <100 μm) | Wafer manufacturing Epitaxial growth Diffusion | Precision machining (graphite) Low pressure chemical vapor deposition (LPCVD) | High density Strong bonding High purity High thermal conductivity Corrosion resistance Anti-cracking |

Our Advantages

Advantages of SiC Coated Graphite Wafer Carrier

1. Enhanced Durability: The SiC coating increases the wear resistance of the graphite material, reducing the risk of degradation over multiple uses.

2. High-Temperature Stability: The Wafer Carrier can tolerate the extreme temperatures common in epitaxial growth furnaces, maintaining its structural integrity without warping or cracking.

3. Improved Yield and Process Efficiency: By ensuring the wafers are handled securely and consistently, the SiC-coated graphite Wafer Carrier helps improve the overall yield and efficiency of the epitaxial growth process.

4. Customization Options: The carrier can be customized in terms of size and configuration to meet the specific needs of different epitaxial reactors, providing flexibility for a wide range of semiconductor applications.

Advantages of Hunan Dezhi New Materail

1. Fast delivery response: Sample delivery 7-15 days & bulk delivery 1 month

2. Flexible customization service: Dedicated production lines to match customer needs & Personalized service For product solution support

3. Professional technical support: Professional material testing and analysis center & Quickly cooperate with development and verification needs

4. Robust supply chain: Stable supply chain system, Many long-term cooperative suppliers with good reputation.

Certifications

FAQ Q. Are you a factory or a trading company?

A: we are the leading factory of SiC Material Components For Semiconductors in China.

Q. When can i get the price?

A: We usually quote within 24 hours after getting your detailed requirements,like size, quantity etc. .

If it is an urgent order, you can call us directly.

Q. What about the lead time for mass product?

A: The lead time is based on the details of the product, generally 20-30 working days.

Q.What is your terms of delivery?

A: We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way for you.

Besides that, we can also shipping by Air and Express.

>> Ja Monocrystalline Modules 540W 545W 550W Solar Panels with Good Price

>> 60L Door Pull out Outdoor 50L Pop-up Dustbin Trash Bin

>> Small Size 3015bt Table Top 3D Metal Stone Engraving Machine CNC Wood Router for Sale

>> 18V/20V Cordless Range Battery Powered Brushless Reciprocating Saw

>> GBLXM-1200 Multi Heads Polishing Machine for Granite

>> Beke 20mm Thickness Steel and 3 Meter Metal Sheet 4 Rollers Hydraulic Rolling Machine

>> High Efficiency Bamboo Charcoal Briquette Machine Price for Hot Selling

>> All-Terrain Movable Badminton Post with Enhanced Durability

>> Contex IQ Flex flatbed scanner

>> RAM Type Milling Machine Wn736c High Rigidity Mill Large Table Milling Machines

>> Hot Selling Rapid Action Survival Kit Utility Medic Tactical Pouch Medic Bag

>> Infinitely Variable Speed and Flexible Commutation Electric Tapping Machine

>> Portable Hand-held Light weight Falling Weight Deflectometer LWD

>> Wholesale Fashion Decoration Zigzag Lace Trimming Ric Rac Trim Lace

>> Armor 100%Cotton Summer Men Round Neck T-Shirts

>> Ring Chain Electric Hoist, Load 1 Ton, Lifting Double Speed

>> CNC Machining Processing Customized Sewing Machine Parts/Accessories

>> Good Quality Paulownia Board\Treated Pine Timber\Wood and Plastic Composite Outdoor Decking Floor

>> Disc Stack Centrifuge for Coconut Oil Processing

>> Tiffany Table Lamp European Retro Simple Bedroom Glass Table Lamp (WH-TTB-84)

>> Exterior Roof Decor PVC Soffit Vinyl Siding Cladding Wall PVC Profile

>> Kernel Oil Expeller, Soybean Oil Press with Press Filter

>> Jinan Factory Price Mold CNC Engraver Milling Machine 6060 Atc Metal Mould CNC Router

>> High Quality Custom Rounded Woven Badge Printing Woven Patch for Clothing/Caps

>> 02-08 87940-PROBO-M Manual Side mirror for left side Door mirror for PROBOX

>> Ajustable Pipettor Universal Racked 1000/1250UL PP Material Plastic Pipette Tips

>> 100mm Chip Free Resin Filled Diamond Grinding Cup Wheel for Stone

>> Amber Strobe Beacon LED Forklift Light

>> Large Capacity Automatic Four Nozzles High Accuracy Cotton Polyster Filling Machine

>> China Powder Coated Yellow Gas Cylinder Cage/Gas Bottle Cage