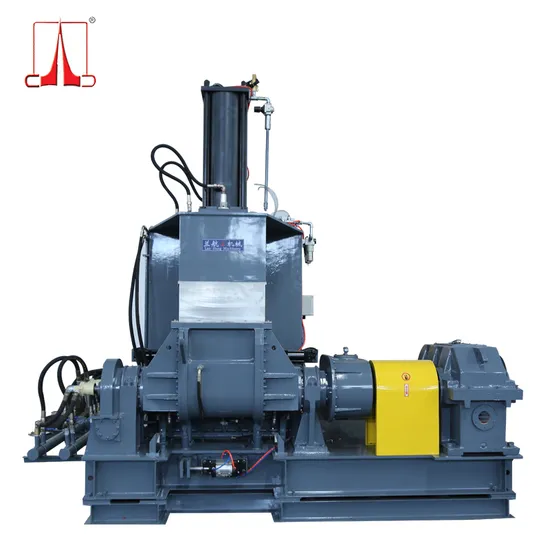

3L 5L Lab Rubber Dispersion Kneader Rubber Banbury Mixer

Basic Info.

Model NO.

X(S)N-3L 5L

Control Type

PLC

Automatic Grade

Semi-Automatic

Power Source

Electric

Type

Rubber Mixer

Working Volume

5L

Loading Type

Backing Charing

Motor Power

7.5kw

Color

Customized

Rotor Type

Tangential

Air Pressure

0.6-0.8MPa

Discharging Type

Tilting Discharging

Usage

Rubber Mixing

Key Word

Rubber Kneader

Weight

1200 Kgs

Discharing Type

Worm Gear Motor

Rotating Speed Ratio of Rotors

1:1:2

Rotating Speed of Drive Rotor

30r/Min

Material

SUS304

Invertou

ABB

Transport Package

PE Film Wraps

Specification

X(S)N-5L

Trademark

LANHANG

Origin

China Jiangsu

HS Code

84778000

Production Capacity

100sets/Year

Product Description

PRESSED KNEADER DISPERSION KNEADER Product Description Technical Parameters:| ITEM/MODEL | LX-1.5L | LX-3L | LX-10L | LX-35L | LX-55L | LX-75L | LX-100L | LX-160L | LX-190L | LX-270L | LX-410L |

| ROTOR TYPE | TANGENTIAL ROTORS | ||||||||||

| RAM DRIVER | HYDRAULIC or PNEUMATIC | ||||||||||

| Total Volume | 1.5L | 3L | 10L | 35L | 55L | 75L | 100L | 120L | 160L | 270L | 410L |

| FILL FACTOR | 75% | ||||||||||

| MainRotor Speed(r/min) | 6~6 8~80 10~100 | 6~6 8~80 10~100 | 4~40 5~50 6~60 | ||||||||

| Rotor speed ratio | 1:1.17 | ||||||||||

| Power(kw) | 22 37 55 | 37 55 75 | 75 | 110 | 132 | 160 | 220 | 400 | 500 | 1250 1500 | 1250*2 |

| Weight(T) | 2,3 | 3 | 6 | 9 | 12.5 | 16 | 22 | 28 | 36 | 45 | 60 |

| ITEM/MODEL | LH-1.5Y | LH-3Y | LH-10Y | LH-35Y | LH-55Y | LH-90Y | LH-135Y | LH-160Y | LH-190Y | LH-250Y | LH-320Y | LH-410Y |

| ROTOR TYPE | INTERMESHING ROTORS | |||||||||||

| RAM DRIVER | HYDRAULIC or PNEUMATIC | |||||||||||

| Total Volume | 1.5L | 3L | 10L | 35L | 55L | 75L | 100L | 120L | 160L | 270L | 410L | |

| FILL FACTOR | 65% | |||||||||||

| MainRotor Speed(r/min) | 6~60 8~80 10~100 | 6~60 8~80 10~100 | 4~40 5~50 6~60 | |||||||||

| Rotor speed ratio | 1:1 | |||||||||||

| Power(kw) | 37 55 75 | 55 75 90 | 110 | 160 | 250 | 280 350 450 | 500 630 750 | 630 750 800 | 750 1000 1250 | 1250 1500 | 1250 1500 1800 | 2500 |

| Weight(T) | 2.8 | 3.5 | 6.6 | 9.5 | 12.9 | 16.5 | 22.5 | 28.5 | 37 | 46 | 61 | 79 |

Introduction:

Dispersion Mixer has become the most commonly used type of mixer in the rubber and plastics industries. The tilt mixer with its uniquely designed rotors, rotor blades, mixing chamber and pressure lid allows for thorough material flow and controlled shear mixing within the mixing chamber. This intensive mixing achieves a uniform compound mixture with exceptional dispersion of materials.

Features:

1.Blade of rotors are well designed for better dispersion&faster cycle time.

2.Effective cooling system to control overheating.

3.Easy Cleaning for color change.

4.Hydraulic tilting system for trouble free working.

5.Simple operation through quality designed electric panels&safety.

Advantages of our mixer:

Mixing rotors adopts Ni-Cr-Mo alloy, the wearing parts welded German imported wearing resistant high speed steel, and chrome plated.

Mixing chamber body adopts wear resistant alloy integral casted, tangential area welded German imported wearing resistant high speed steel, and chrome plated.

Side wall anti-leakage device adopts high advantage material: high pressure casted epoxy glass cloth with the characteristics of wearing resistant, easy for maintenance, not easy to cause chemical reaction.

Pressuring cover adopts "M" structure, which ensures material mixed more evenly and thoroughly.

Main motor electrical current meter in the control panel; During production, once when the mixer chamber pressure is too high, and current exceeds the set value, the terminal contactor with solenoid valve will control the pressuring cover's raising to reduce down the pressure.

>> 2018 New Skmei Watch men Fashion digital multifunctional Wristwatch With compass and calories display

>> Good Heat Resistance Aliphatic Urethane Acrylate UV Resin Application for 3D Printing

>> Bamboo Bread Slicer for Homemade Bread Loaf Wooden Bread Cutting Board with Crumble Holder Foldable and Adjustable

>> U KISS Automotive Parts Front Car Grille For Benz W 205 C CLASS change to C 63 Amg GTR Style Black Silver Car Grille

>> 3 Phase Decanter Centrifuge for Oil From Shenzhou China

>> Automatic Rotary Plastic Slippers Making Machine

>> 6400500103 Timing Gear for Mercedes-Benz Vito Engine OM668 OM 668 TG1083

>> Elegant Makeup Bags White Black Leather Storage Organizer Cosmetic Bag for Travel

>> Smart Tag UHF RFID YUKAI 860~960mhz Anti Metal Surface RFID PCB UHF Tag For Tools Management

>> Module spare parts SCXI-1001

>> Factory China Mini Digger Micro Digger 1 Ton Mini Excavator 1.8 Ton 3.5 Ton Mini Excavator 5 Ton Small Excavator Prices

>> Competitive Price M6-M30 Touch Screen Control Servo Electric Tapping Machine

>> New arrived Mini floating fish feed fish meal pellet making machine fish food pellet machine

>> Amazing Gymform Dual Shaper (GDS 0309)

>> Auto Parts Front Bumper Car Front Bumper For Prius 2012 - 2015

>> Swiss Type Horizontal CNC Lathe Prcessing Center CNC Machine with High Precision

>> 350L Manufacture Gasoline Concrete Mixer Machine with 2 Wheel

>> Non Woven Fabric 100% Polypropylene Melt-Blown Nonwowen Fabric Medical Respirator 25GSM Fabric Production Line

>> Factory Custom Mold Wholesale Shockproof Silicone TPU Case for iPhone 15 Promax Plus Ultra Mobile Phone Case iPhone 11 12 13 14 PRO Max Back Cover

>> High Performance Gold Mining Machine Small 10t/HWet Ore Grinding Ball Mill

>> Industrial Grade Engineering TPU Printable Dual Color 3D Printers Print Size 400*400*400mm

>> Garment Bags for Travel Garment Bags Custom Logo Hanging Suit Bag for Traveling Monogrammed Closet Clothes Storage

>> MAICTOP car accessories car front grid front grille for landcruiser 2012-2015 fj200 grj200 uzj200 lc200 new design

>> Remote Control Car Parts Auto Electric Tailgate Liftgate for BMW X1 E84 M Sport Power Trunk

>> High quality factory price auto parts grille for CHEVROLET AVEO 2009-2013 OEM 96694759/95365210

>> Dart Board Set Axe Cut Wood Target Dart Sport Toy

>> Advanced Metal Recycling Equipment for Custom Motorcycle Components

>> Hot Selling High Quality Brake Vacuum Pump for Freelander 2 Range Rover & Jaguar & Ford

>> ferro scanner reinforcement cover measuring device steel bar locator

>> Spc Rigid Core Unilin Click Lock Multi-Layer Stone Plastic Laminate PVC Floor