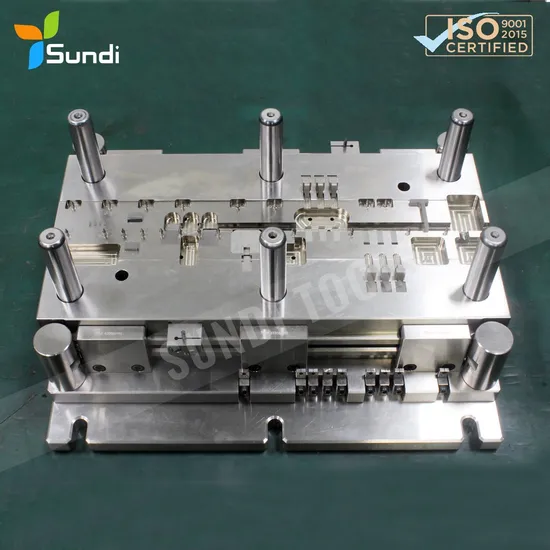

Sundi Precision Molding Tooling Manufacturer Metal Sheet High-Speed Progressive Die Tooling Stamping Mold

| US$300.00-2,000.00 | 2 Pieces (MOQ) |

Basic Info.

Model NO.

B080001-1

Material

Carbon Tool Steel

Processing Method

Punching and Shearing Mould

Technics

Forming Die

Process Combination

Progressive Die

Manufacturing Technology

Computer Technology

Driving Motor Type

Hybrid

Mold Cavity Technology

EDM Milling

Milling Speed

High Speed

Parts Detection Method

Measurement of Three Axis NC

After-sales Service

1year

Surface Finish

0.3-0.4 Micron

Tolerance

+/-0.002mm

Testing Equipment

CMM\Profile Projector\Tool Mic\Height Gaugeroscope

Machining Time Shift

Day & Night Two Shifts to Speed up The Production

Carbide Source

Everloy, Fujilloy, Ceratizit, Kenna

Transport Package

Cartons or Wooden

Trademark

SUNDI

Origin

Wuxi China

HS Code

8207300090

Production Capacity

50000/PCS Year

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 100.00cm

Package Gross Weight

20.000kg

Product Description

Product DescriptionBenefits of Using Sundi Metal Stamping Dies

| Metal stamping dies are specialized tools used in manufacturing to cut, shape, and form sheet metal into specific parts and components. These dies consist of a male and female part that work together to stamp out the desired shape from a metal sheet, providing high precision and efficiency in mass production. For more than 20 years, Sundi Tool has been at the forefront of manufacturing, designing and building top-of-the-line metal stamping dies. We share our industry experience as a professional tool and die maker specializing in progressive, composite, transfer and forming dies for a variety of customers. | |

| High Precision and Accuracy | Metal stamping dies offer high precision and accuracy, ensuring that the stamped parts meet the exact specifications and tolerances required for the application. |

| Cost-Effective Mass Production | Metal stamping dies enable cost-effective mass production of parts, reducing the per-unit cost and increasing efficiency in high-volume manufacturing. |

| Versatility in Applications | Metal stamping dies are versatile and can be used to produce a wide range of parts and components for various industries, from automotive to electronics and medical devices. |

| Durability and Strength | Metal stamping dies are designed to withstand the high pressures and forces involved in the stamping process, ensuring long-term durability and performance. |

Company Profile

Our Advantages

Certifications

Packaging & Shipping

FAQ

CAN YOU MAKE THE CUSTOMIZED PARTS?

Of course, we also take the design for clients and make the special parts and mold, satisfied with customers of high quality.

HOW ABOUT THE LEAD TIME?

The lead time is based on the quantity and complexity of the ordering tools. it's normal for 10-20 days, If urgent,

we'll arrange the production with top priority to reduce lead time.

DO YOU KEEP A STOCK OF YOUR PRODUCTS?

We will stock for the regular ordering parts, for the customized product we need to machine them according

to special requirements.

CAN YOUR ENGINEER JOIN OUR PROGRAM DESIGN

We're very pleased to be working with you, we can offer our idea and design.

IS THERE A PRICE LIST?

Feel free to contact our sales to get the last price list and offer.

>> Taijia concrete rebar detector rebar locator concrete scanner for sale pachometer rebar locator

>> Best Selling 32 Inch C/J/S Curved Gaming Monitor with Touch Screen for Casino Machine

>> Super Quick Charge Cable for iPhone 11

>> Wholesale Price Bicycle Parts of Bicycle 7 Speed Free Wheel with High Quality

>> Factory Price Food Processing Make Automatic Sausage Stuffing Machine / Sausage Production Line / Hydraulic Sausage Making Machine in USA Europe South Africa

>> Aluminium Alloy Wardrobe Accessories Heavy Duty Clothes Hanging Oval Closet Rod

>> Half Price Discount Jinko Ja Longi Used 250W 250watt 440W 450W 550W 100 200 250 300 400 450 500 Watts Solar Panels

>> Taijia portable concrete scanner rebar concrete steel locator rebar scanner and locator

>> Textile Machinery 8kw Ss Laser Cutting Steel Machine 1530 Fiber 4020 6000W Hot

>> Gmb2518 CNC Guide Rail Drilling and Tapping Gantry Machining Center

>> Reusable Water Bomb Balloons, Summer Toy Water Toy, Pool Beach Toys for Kids, Outdoor Activities Water Games Toys Self Sealing Water Toy Splash Ball 6 Pack

>> Portable Saw Mill Wood Door Cutting Machine CNC Band Saw Machine Wood Cutting Machine for Door Cutting

>> Needle Loom for Felt Carpet Making Non Woven Needle Punching Machinery

>> Gold concentrator rotary drum washer for natural gold recovery

>> Hualong Stone Machinery Hlsq-650 Tile Cutter Siemens Bridge Saw 5 Axis Stone CNC Bridge Granite Cutting Machine

>> High Quality Steady Kainiu Diesel Mini-Tiller

>> Vmc855 High Precision 8000-12000rpm Machinery Metal Cutting CNC Vertical Machining Centre

>> 4 Axis Slant Bed Twin Double Multi Spindle Lathe CNC-960t Fanuc CNC Turning Center with Twin Y Axis

>> Horizontal Tensile Test Bed, Chain, Sling, Wire Ropes Horizontal Tension Tester

>> Jc 7HP 170f Multifunctional Micro Tiller Rotary Tillerweeding Cultivator

>> YY home Aluminium Awning Window with impacted glass

>> Zerun Solid Wood Bookcase for Home Office Furniture

>> Auscp SL70 High-Speed Backgluing and Backlining Machine Perfect Binding Notebook Making Machine

>> up and Down Folding Window Lifting and Sliding Customized Milk Tea Coffee Shop Aluminum Alloy Easy to Pull up and Hover up and Flip Window

>> Deluxe Elastic Bandage with Self-Closure, 7.6cm*4.57m (HEB-002)

>> White More Than 5 Years 3D Print Wall Tiles Kitchen Tile

>> Small CNC Machine Double Sided Turret Turning Metal Inclined CNC Lathe Machine

>> Hot Selling Stainless Steel Pipe Industrial Tube Manufacturing Machine

>> Small Vertical Soft Plush Toy Stuffing Making Machine Teddy Bear Filling Machine

>> High Quality China Disc Plough Disk Plough for Tractor for Sale