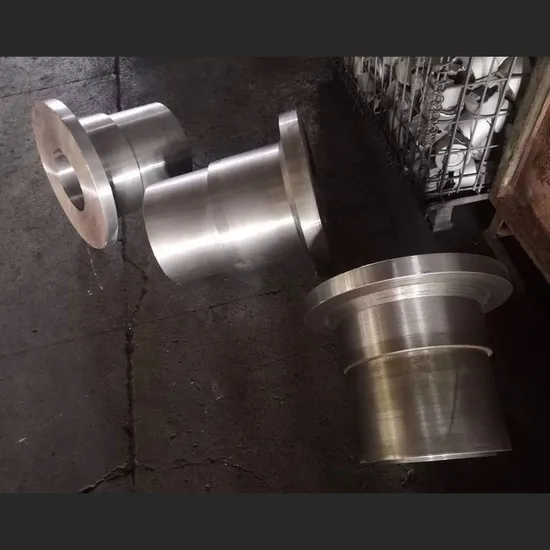

Customized Steel/Aluminum/Brass/Iron Hot Cold Drop Die Forging CNC Machining

| US$1.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

hs-1174

Forging Forming Method

Mold Forging

Power Source

Hydraulic Pressure

Feature

High Efficiency

Certification

CCC, ISO9001, CE

Warranty

12 Months

Customized

Customized

Advantage

Use Widely

Condition

New

Quality Guarantee

1 Year

Heat Treatment

as Your Request

Hardness

as Your Request, Hb, HRC...

Size

Customized

Finishing

Anodized, Chrome Plating, Sandblast

Standards

DIN, ASTM, GB, JIS, ANSI, BS

Drawing

CAD/Dxf/STP/Rough Drawings

Quality Control

100% Inspection

Package

Exporting Standard Packaging

Service

Expert of OEM ODM

Application

Oil and Gas Industry

Transport Package

Wood Cage or as Your as Your Request Investment C

Specification

According to the drawing

Trademark

No OR OEM

Origin

Ningbo, China (Mainland)

HS Code

7318290000

Production Capacity

5000 Piece/Pieces Per Month

Packaging & Delivery

Package Size

450.00cm * 450.00cm * 500.00cm

Package Gross Weight

1000.000kg

Product Description

CNC Machining Grinding Stainless Steel Pin Shaft Axle Used for Small HomeProduct Description

We provide highest standard manufacturing services for CNC machining/ forging / casting / stamping /metal fabrication...

Forgings including: mold forging , free forging, smith forging,open die forging, hot forging, cold forging.

| Model NO. | 565689 | | Processing Object | Metal |

| Molding Style | Forging | Molding Technics | Pressure Casting | |

| Application | Aerospace Part, Marine Parts, Mining Parts | Material | alloy steel, stainless steel, 4140, 4340,1045,1020,SS410,316,304 | |

| Heat Treatment | Tempering, normalizing, tempering, quenching, surface hardening, solid solution | Surface Treatment | Powder Coating | |

| Forging Tolerance | +/-0.1mm | Standard | AISI, ASME, DIN | |

| Certification | CE, RoHS, ISO 9001:2008 | Tolerance | 2.0mm -0.01mm | |

| Usage | Railway Parts, Oilfield Equipments, Auto Parts | Inspection | Material, Ut, Hardness, Tensile, Yield | |

| Surface Roughness | Ra6.4-Ra0.8 | Weight | 1kg to 10000kg | |

| Size | 10mm to 10000mm | Trademark | OEM | |

| MOQ | 1PCS | Origin | China | |

| Specification | 10mm - 10000mm | | |

Production Parameter

• Material: Alloy steel,Carbon steel,Carburizing steel,Quenched and tempered steel

• Heat treatment: Normalizing,Annealing,Quenching&Tempering,Surface Quenching, Induction hardening

• Machining: CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling

• Gear Machining: Gear Hobbing,Gear Milling,CNC Gear Milling,Gear Cutting,Spiral gear cutting,

• Gear Cutting

• Inspection: Chemical Composition Test,Ultrasonic Test,Penetration Test,Radiographic Test,

Magnetic Test,Tensile Strength Test,Impact Test,Hardness Test,Dimension Test.

We can provide forging from 1kg to 5Ton. And make precison machining. Also have welding and assembly capabilities.

Company Profile

For more products,please click here

Our Advantages

1.Good Quality with strict inspection process. control the tolerance up to +,-0.002MM.

2.Competitive Price and prompt delivery time.

3. International Quality Certified

4.Skilled workers

5.Warranty After-sales-service

FAQ

Q1: How can I get quote ?

A1: pls send us PDF,JPG,or other 2D files and 3D drawings. if you don;t have drawings. pls send me samples.

Q2: How you guarantee the quality?

A2: Our production will be strictly comply with the drawing requirements.we offer details photos and inspected reports to let you confirm before shipment.we will take the responsibilty for any quality issue.

Q3: What is payment term?

A3: 30% depoist in advance and the balance to be paid against the copy of BL.or LC at sight.

Q4: How about the shipment and package?

A4: If you have nominated forwarding company, we can contact him, if you don't have .my company will organise the best-service forwarding company with the lowest shipping cost.

Q5: How to pack the cargos?

A5: If you have special packing request, pls send us design, my company will make the package exactly according to your designs.

or my company use our own good and standard package (carton or wooden box, or pallet or others according to different products )

>> Light Weight Round Square Holes Perforated PP and PE Plastic Sheet

>> 6 Ovens Use Oil Heating Changer for Textile Finishing Process Fabric Setting Coating Machine

>> Hot Rolled Wnm400 Wearing Steel Plate Wnm450 Wear Plate Wnm500 Wear Resistant Steel Plate Nm400 Nm450 Nm500 Steel Plate for Sale

>> Q235 Galvanized Steel Coil with Small Spangles

>> Bulk order good price exterior aluminum bi folding door patio aluminum folding glass door

>> Hot 3-layer metal shelf space saving bathroom storage rack on washing machine washing machine rack

>> Auto body parts PP plastic car rear bumper for Chevrolet Epica

>> Synchronous CNC Sheet Bending Press Brake

>> YOYIK supplies Color camera WV-CP504D

>> Factory Manufacturer Decorative Ring Mesh Interior&Exterior Wire Mesh for Decorative Curtain & lamps

>> Hardware Electric Galvanized Hot DIP Galvanized 6*31 Ws FC Cable Steel Wire Rope

>> Double Tempered Low Profile Aluminum Alloy Double Glass Slide Window

>> Poultry Farm Equipment Automatic Battery Cages Laying Hens Egg Layer Chicken Cages

>> Hotel Dining Room Table Chair Set Booth From Guangdong Leather Wooden Furniture

>> Used Concrete Floor Grinding Machine

>> Best Price Mean Well Driver Waterproof Outdoor LED Flood Light

>> High Accuracy Machine Satellite Land Leveler Leveling Machine Agricultural Equipment GPS Grader

>> powder coated expanded metal mesh for car grille and car accessories

>> Estop China Manufacturer Fixed Gantry Precision Surface Grinding Machine

>> Side-Shift Hydraulic Arm with Hammer Blade Verge Flail Mower

>> 1stshine Ceiling Fan Factory OEM D. I. Y ABS Blades Energy Saving Smart Remote Ceiling Fan

>> Food Mixer Stainless Steel Vacuum Roll Kneading Machine Meat Vacuum Tumbler Machine

>> High Quality Three -Row Multiple Drilling Machine

>> Ranbem 110V 220V Quite Low Noise Commercial Smoothie Ice Maker Blender and Mixer with Sound Enclosure

>> Best FM Radiopedo Meter with Dual Head Display for Outdoor Sports Pedometer

>> Hand-Held Micro-Cultivator Is Used to Weed and Loosen Soil on Mountain Farms

>> Durable Waterproof Travel Laptop Backpack with USB Charging Port

>> CE Approved 2pole 4pole 11kw 15kw Y2 Series Electrical Motor

>> American Exterior aluminum thermal break casement door french glass door

>> Chinese Excavators 6ton, 8ton, 13ton Digger Earth Moving Machinery Hydraulic Wheel Excavator