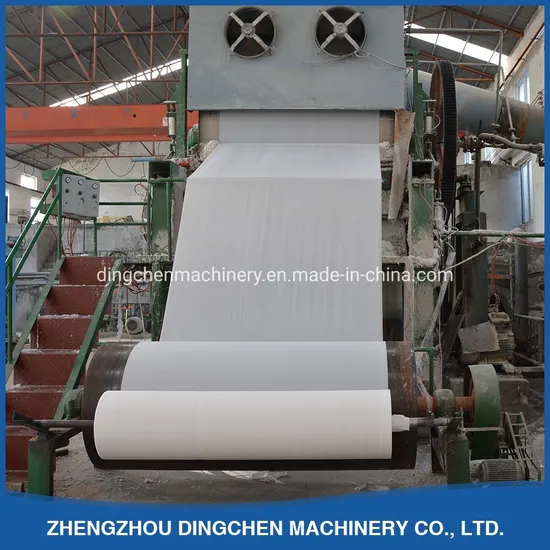

1092mm Toilet Tissue Paper Making Machinery

| US$90,000.00-150,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

1092mm

Certification

ISO

Condition

New

Control

Automatic

Embossing Type

Full-Embossing

Embossing Roller

Wool Roller

Tissue Packaging

Bag

Function

Cutting

Tissue Type

Mini

Voltage

380V

After-Sales Service Provided

Engineers Available to Service

Capacity

1.5-2t/D

Colour

Optional

Product Type

Toilet Tissue

Rail Guage

1800mm

Raw Material

Wood Pulp, Recycling Paper

Grammage

18-40G/M2

Processing Type

Toilet Paper Making Machine

Model Number

1092mm

Type

Lavatory Paper

Sheet Former Type

Cylinder Mould

Paper Thickness

Thin Paper

Automation

Automatic

Customized

Customized

Transport Package

Standard Package

Specification

be specified

Trademark

Dingchen

Origin

Qinyang

HS Code

84392000

Production Capacity

5 Sets Per Month

Product Description

1092mm Toilet Tissue Paper Making MachineryTechnical parameter

1.Raw material: recycled paper

2. Output paper: toilet paper

3. Output paper weight: 15-25g/m2

4.Capacity: 2 tons per day

5.Paper width: 1200mm

6.Wire width: 1450mm

7.Working speed: 100-150m/min

8.Designing speed: 180m/min

9. Rail gauge: 1800mm

10. Drive way: Alternating current conversion speed, sectional drive.

Features:

1. customer-oriented design principle

2. high rate of output with high quality

3. mature skills and technology support

4. considerate pre-sales and after-sales service

5. appropriate discount can be negotiated

Main Equipment Parts:

1. cylinder part: φ 1000mm×1450mm stainless steel cylinder mould 1set, φ 300mm×1100mm couch roll 1set,coated by rubber, rubber shore hardness 38ºC±2.

2. Dryer part: φ 1500mm×1450mm alloy dryer can 1 set, 1group scraper knife. φ 350mm×1100mm touch roll 1set, coated by rubber, rubber shore hardness 90ºC±2.Mechanical loading device.

3.Winding part: φ 900mm×1450mm sweat cylinder (1pc), φ 280mm×2250mm fly rubber roll( 1pc ).rubber HSD75°±2. winding on the sweat cylinder.Equipped with the 250 speed reducer(1 set)

III. Main equipment list for paper production line

| No. | Item |

| 1 | Stainless steel cylinder mold |

| 2 | Alloy dyer cylinder |

| 3 | Exhaust hood of dryer cylinder |

| 4 | Φ600 Axial-flow ventilator |

| 5 | Winding machine |

| 6 | 13 type roots vacuum pump |

| 7 | Air compressor |

| 8 | Frequency conversion controlling cabinet |

| 9 | 1092mm automatic rewinding machine |

| 10 | Tissue paper cutting machine |

| 11 | Cylinder type wheat straw cutter |

| 12 | Ф3000*3000mm Cooking pool (underground 2000mm,overground 1000mm) |

| 13 | Vertical mixer with BLD cycloid reducer |

| 14 | 220kg Holland pulp beating machine |

| 15 | 1.8m2 High frequency vibrating screen |

| 16 | 35m3 bleacher |

| 17 | Ф380mm double disc pulp refiner |

| 18 | Low concentration sand remover |

| 19 | 0.6m2 Pressure screen for cylinder mold |

| 20 | Ф500mm Impeller |

| 21 | Electrical operation cabinet |

| 22 | 1T Boiler (burning natural gas) |

Company Information

Zhengzhou Dingchen Machinery Co., Ltd., located in Central China, is a professional machinery manufacturer focusing on the R&D and production of paper making machines.Our products include paper making machines,pulp making machine,parts and paper converting machines such as kraft paper machines,corrugated paper machines,tissue/toilet paper machines,office paper machines, newspaper machines and so on. Our factory gathers and trains many essential technicians and management system to ensure all products meet the quality of ISO and update constantly!

Our products have been exported to many countries and regions, such as America, Egypt, India, Fiji, Iran, Ghana ,Paraguay, Russia, Syria,Pakistan, Tanzania, and Uzbekistan. Our products and services have won customers' consistent affirmations.have won customers' consistent affirmations.We have a large scale of products regarding paper machinery, including:A.Pulping equipment (D-type hydrapulper, cleaner, DD refiner, pressurescreen, screen basket, pulp pump etc.)B.Paper machinery (Tissue/Toilet paper machine, Multi-fourdrinier papermachine, head box, cylinder mould, dryer cylinder, roller etc.)C.Paper making finished devices (Paper calender, pope reel,size press,paper rewinder etc.)Meet customers' requirements and exceed customers' expects.We wish to found long-termcooperation with your companyTechnical Advantage1.Experienced producing team2.Advanced technological strengthProduct Advantage1.Through the international authentication2.The same material the most preferential price3.A lot of varieties for the customer to chooseService Advantage1.Technical consultation2.Project evaluation3.Detailed design of factory4.Installing and testing the whole production line5.Training engineers and workers6.Supplying spare parts for long timeThe business process1.send your requirements:raw material,capacity,paper grammage2.we make the solution to you3.come visit and negotiate4.sign contract5.first payment6.production7.pay spare money8.delivery9.installation ,training,test run10.production consultlation

Packaging & Shipping

Our Services

FAQ

Var20220726

>> UV Protection Fishing Net (FN04-FN36)

>> China Top Toilet Block Making Machinery

>> Bar Hydraulic Flip Plow Is Farm Tillage Garden Plow with Reasonable Structure, Strong Rigidity, High-Quality Materials and Beautiful Appearance.

>> 100% Natural Bamboo Cheese Board Set 4 Hidden Drawers Food Serving Charcuterie Board Bamboo Cheese Board With Knife Set

>> PDD405 ABB module supply

>> Air Transportation of Atomizer to Myanmar, Sensitive Goods, Cosmetics, Mobile Power Banks

>> Single-Screw Ribbon Feed Mixer Machine Slhy Series Animal Fodder Blending Machine

>> Professional Customizationprecast Concrete Slab Automatic Cutting Machine

>> 2022 New Arrival 2000 battery LED Smart display USB Portable eyelash extension mini lash Camera hanging neck Fan

>> IBC Tank 1000L/ Plastic IBC Tote Tank Food Grade

>> High Performance Carbide Insert for CNC Metal Cutting Tools

>> Hot Sell Factory Price Orthopedic Implants Pfna Nail, Long Proximal Femoral Nails

>> 18V 20V Cordless Brushless Battery Lithium Accumulator Hand Impact Screwdriver Li-ion Power Drill

>> Black/Grey/Yellow/Beige/Rusty Hand Carved Custom Shaped Granite Stone Vessel Bathroom Sink with Polished/Chiseled/Split Exterior

>> Large Area Thermal Evaporation Coating System for Glass Panel Coatings

>> Custom Gym Clothing Two Piece Sportwear Set Shorts Yoga Wear Three Color Leopard Print Yoga for Women

>> Metal Carbon Steel Cutting Fiber Laser Cutting Machine 1390 1325

>> 1-100UF Mfd 450V Air Conditioning Water Pump Washer Washing Machine Cbb60 AC Motor Start Run Film Capacitor

>> Quadruplex Service Drop ACSR Neutral Conductor Chola

>> 6 Axis CNC Hydraulic Press Brake with Ad66t Controller

>> Full Automatic High Production Single Side Down and Fiber Filling Machine with Eight Scales and Big Grams (RM2-8D)

>> Food grade Stpp sodium tripolyphosphate for clams

>> We67K Series Electro-Hydraulic CNC Press Brake Machine for Bending Metal Sheet

>> Steel Plate Bending Machine CNC Press Brake with CT600 System

>> Waste Plastic 500-2000 Kg/Hour Pet Bottle Crusher Shredder Recycling Machine Line

>> Zenitel P-66-VMP/10 Hand mic. with PTT, 10m cable, no plug 2330040022

>> Support Pattern Tracking 12 Needles 2 Head High Speed Hat T-Shirt Computerized Automatic Embroidery Machine

>> 18V/20V Lithium Battery Range SDS Plus Brushless Motor Cordless Rotary Hammer

>> cheap exterior steel door designs industrial front flush door

>> factory price 35kHZ 900W portable gun type ultrasonic spot welder handheld plastic induction welding machine