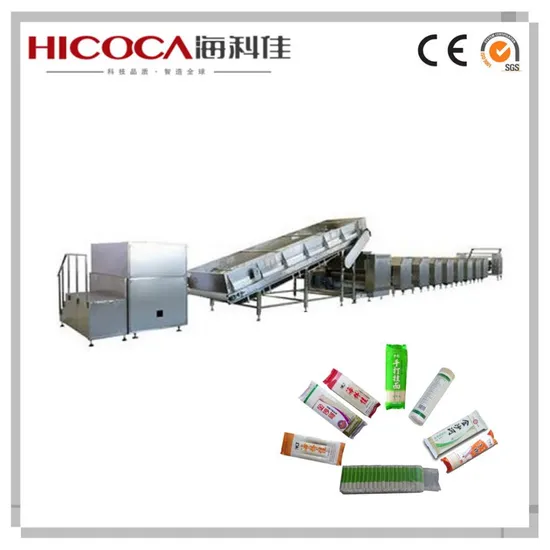

Fine Dried Noodles Production Line

| US$13,500.00-4,200,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HICOCA-GM

Processing Material

Wheat Flour

Application

Stick Noodle, Pasta, Spagetti

Customized

Customized

Certification

CE, ISO9001

Power Source

Electric

Automatic Grade

Automatic

Series

T Series - Pallet Wrapping Machine

Capacity

20-75 Ton/Day

Feature

Automatic Splicing System

Calendering Rollers

High Chrome Alloy Steel

Noodle Thickness

0.6mm-1.4mm

Noodle Width

0.8mm-3.0mm

Applicable Industry

Food Processing Machine

Machine Material

Food Grade Stainless Steel

Color

Sliver

Control System

PLC

Compressed Air

160-200 Kw

Product Shape

Square or Round

Energy Source

Electric

Packing Capacity

30-70bags/Min

Zero Adjustment

Automatically or Manually

Transport Package

Wooden Case

Specification

6700mm*3400mm*1650mm

Trademark

HICOCA

Origin

Qingdao, China

HS Code

8438100090

Production Capacity

10 Sets/Month

Product Description

Product DescriptionSTICK NOODLE MACHINE LINE

Advanced technology and process breakthrough

1 person one-hand assisted start-up, one-key setting of pressing ratio, Intelligent matching of noodle mixing and pressing, automatic collection and transmission of information and data, memory and storage of production mode, remote diagnosis and analysis of fault, intelligent maintenance and repair, etc.

Production Process:

Horizontal double-shaft dough mixing machine

1. The mixing paddle adopts a special angle design to push the flour to move in different directions forward and backward, which improves the uniformity of mixing.

2. The flour and water are mixed evenly, and the dough can contain more than 33.5% water, with toughness, stickiness, extensibility and plasticity.

3. Adopting special gear reducer transmission box, setting perfect lubrication and sealing device, which greatly improves the working condition of transmission device, reduces the noise level, improves transmission efficiency and prolongs service life.

4. Equipped with timing alarm device, stirring to the specified mixing time will automatically generate a signal, and equipped with emergency stop button, proximity switch and other safety devices.

Maturing conveyor

1. The concept of static fermentation of dough is introduced into mechanization, and the conveyor belt feeding realizes the first-in-first-out of materials.

2. It adopts fully sealed design to avoid moisture dissipation and achieve moisturizing and heat preservation.

3. Adopting spiral beating rod, the beating speed is synchronized with the conveyor belt speed, which ensures the even pressing.

Compound pressing

1. Feeding device adopts direct insert plate type or curved insert plate type.

2. Calendering rolls are made of high hardness and high chromium alloy steel, which has stronger corrosion resistance and ensures long service life. Safety device ensures safety in use, easy to clean, easy to observe and easy to maintain.

3. The pressure roller is driven by high-precision gears, and the material is mostly made of alloy steel, which has high strength and hardness and is durable.

4. The pressure roller adopts high chrome alloy cast roller, with high surface finish and high precision of face sheet thickness. The gap between each pair of pressure rollers is automatically adjusted by servo control.

5. Adopt recipe management, just input the noodle variety specification, then it can realize automatic adjustment.

Continuous calendering machine set

1. Automatic film splicing system: the first set in the industry, invented and patented by Haikejia. The pick-up belt machine can automatically lift and lower to make the dough sheet automatically enter the press roller.

2. The scraper is made of pure copper, and the scraper is controlled by cylinder pushing, when stopping, the scraper is in loose state, which is convenient for cleaning. When the machine is turned on, the program automatically controls the cylinder to press the scraper.

3. All the rollers are driven by independent motor with frequency conversion and double servo motor adjustment method: adjust the roller spacing to realize one-key control.

4. PLC programming automatically adjusts the face belt tension according to the proportional power-on eye detection, which ensures that the running speed of each roller is kept consistent.

5. Real-time detection of bearing temperature, automatic oil filling, eliminating bearing failure caused by lack of oil and reducing labor.

Automatic rod loading machine

Adopt independent rod feeding and storage system, high speed quantitative rod feeding will pick up the noodles into the upper shelf system, PLC control operation, random adjustment of noodle length and two sides neatness, automatic rod return, no need to manually collect the rod, reduce labor and improve work efficiency.

Product Parameters

| NAME | Item | NOTE |

| Alkali water tank | YSH100 | Volume:1000L Material:TANK BODY SUS304# Power:1.5KW,Pump:0.75KW |

| Water measuring & spraying device | YSJ10 | Volume: 110L Power: Pump 0.75Kw With liquid level display ,round type tank,stainless. |

| Double-shaft dough mixer | HMJ200 | Motor Power: 6.5/8 Kw Door opening by manual Volume: 150KgL/per time Material:Noodle contact part: stainless steel |

| Powder falling hopper | LF350 | Material:stainless steel Make according to the actual installation size |

| U type ripen machine | XHJ200 | Power: 4Kw Size: 1600mm×800mm×750mm Volume: 200KgL/per time Materials: contact part: stainless steel |

| Compound and continually rolling machine | MT7-50 | Motor power: 11 kw, Roller width:350mm,total 7 pairs, As the gradation, the roller pair is: First pair roller: Φ180x350mm Second pair roller: Φ180x350mm Third pair roller: Φ240x350mm Fourth pair roller: Φ180x350mm Fifth pair roller: Φ180x330mm Sixth pair roller: Φ162x330mm Seventh pair roller:Φ162x330mm Frequency control. |

| Rod feeding Machine | GT450 | Total Power: 1.5KW |

| Noodle cutter | ZJQ800 | Power: 1.1kw Noodle length can be adjusted, Frequency control. |

| Rod elevating device | SJ350 | Carbon steel. |

| Drying device | PHF30 | Power: main1.1 kw×2 ( Frequency control) industrial fan 0.75 kw×13, Moisture removal fan 0.6kw×6 Drying time:~4hrs. 5row , length 50m stainless steel rods,4000 pcs. |

| Rod unloading | XJ350 | Power 1.5kw ( Frequency control) carbon steel |

| Ration length cutting Machine | ZQM50A | Power: 0.8kw Noodles length 130mm-298mm, adjustable |

Certifications

Company Profile

Powerful team-----HICOCA has more than 460 employees, more than 90 people in R&D and more than 60 people in technical service.

Advanced Technology-----The manufacturing base is equipped with world advanced processing and manufacturing equipment such as German imported laser cutting processing center, vertical processing center, Frank CNC machine tools, OTC robot welding, etc. It has established a complete ISO9001 international quality system and GB/T2949-2013 intellectual property management system.We have more than 407 national patents, several PCT international patents and 17 software copyrights.

Various products-----The company's products involve: food packaging production line, hang noodle host baking room production line, fried/non-fried instant noodle production line, udon noodle production line, steamed bun bun intelligent production line, rice flour intelligent production line, fresh wet noodle/semi-dry noodle intelligent production line, extruded noodle production line, hand row noodle production line, intelligent dumpling production line

Global reputation-----Business footprint throughout the country's major provinces and autonomous regions, exported to 38 countries and regions abroad.

Packaging & Shipping

Our Customers

FAQ

1. Q: Can your products be customized?

A: Yes. We are a manufacturer of food making and packing machines with 20 years experience, and more than 80 engineers who can design machines according to your special request.

2. Q: What to do if there is a problem with the machine?

A: All machines will be tested before delivery, if there is a problem, we have after-sales specialists can provide home repair.

3. Q: How many countries have you exported to?

A: we have exported to more than 20 countries, such as : Canada, Turkey, Malaysia, Holland, India, etc.

4. Q: What is your delivery time?

A: 30-50days. For special request, we can deliver the machine within 20 days.

5. Q: What about aftersales service?

A: we have 30 aftersales service staff, who have experiene to provide service overseas to assemble the machines and train the customers' workers when machines arrive.

>> Outdoor Sport Game Inflatable Palm Slide for Children

>> Customization New Trendy Good Quality 30s 140GSM Rayon Printed Floral

>> Em slimming sculpt machine electromagnetic field muscle stimulation

>> CNC Gantry Milling Double Column Machining Center XH3022 XH4022 XH5022

>> 200W LED COB PAR Can Stage Light 4X50W Warm Cool White LED COB Blinder Stage Light LED Wash

>> Hsy128 Mattress Production Line Industrial Automatic Fabric Sewing Textile Shuttle Multi Needle Single Quilting Machine

>> Agrieso 3000K 9W 220V Waterproof Flicker Free Dimmable Poultry Layer Lighting Bulb

>> Customized O Shaped Plastic Parts PTFE Bushing Ring Gasket Virgin PTFE Rings

>> High Efficiency Food Composting Machine Turn Food Into Compost Agricultural Machinery

>> high frequency welder 15khz 2600W good price ultrasonic welding machine equipment for plastic pvc welding

>> Custom Design Available High Stability Two-Platen Injection Molding Machine

>> Classic EV1 1K Keychain for VIP Membership

>> DDR5 RAM Fingerprint Unlock Rotation 14.1-Inch Yoga 4K UHD Intel N95 Laptop

>> Module spare parts CB6687-2L

>> Sand Cone Test, Rubber Balloon Test and Nuclear Density Test

>> Soft Face Cleaning Makeup Brush Skin Washing Cleaner Pore Massager Facial Nose Body Care Blackhead Remover Beauty Tools New

>> carbon peel nd yag laser tattoo removal machines

>> Wood Look Santa Claus Fugurine with Tree and Baby Angel

>> china manufacturer product Bath sponge Shower loofah bath mat bulk loofah sponge

>> flashes ipl laser hair removal machine 2021

>> Zxx-E0725 Glass Processing Center CNC Cutout Machine for Minimalist Door Glass

>> EVA Sole Lady Sandal Colorfull Shoes

>> Modified Proctor Moulds and Rammers For Soil

>> Brazilian Human Hair Weaves Peruvian Virgin Hair Weft 100% Natural Human Hair

>> Bench Grinder with Dust Removal Device M3320

>> Taijia High Precision Ultrasonic Thickness Gauge measuring instrument Thickness Meter

>> Rectangular Ultra Slim Matte Black Metal Frame Edge Lit Illumiated Bathroom Mirror

>> High Precision CNC Centerless Grinding Machine Cylindrical Grinder for Long Bars, Bearings

>> Automatic Fabric Slitter Cutter Non Woven Fabric Strip Die Slitting Cutting Machine

>> Stainless Steel A2/A4 Hex Machine Screws Inox AISI 304/316 Hexagon Head Bolts