Fluidized Bed Airstream Micronizing Machine

| US$6,000.00-8,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LQF

Power Source

Electric

Raw Materials

Stainless Steel, Mild Steel;

Surface Treatment

Paint for Ms; Polish/Sandblasting for Ss

Power Supply

for Different Power Supply Application

Ex-Proof

Available

Customized Features

e.g. Light Glass, Special Dimension etc.

Special Treatment

Wear Resistant and Anti-Corrosion Available

Object

Plastic

Drive

Electric

Crushing Degree

Ultra-Fine Mill

Crushing Style

Impact

Principle

Fixed Culling

Cutter Material

Hard Alloy

Finished Surface

Outer Surface Process

Compressive Strength (for Crushing)

100-250MPa

Transport Package

Wooden Case

Specification

LQF-100

Trademark

SENFAN

Origin

China

HS Code

8474209000

Production Capacity

500/Year

Product Description

Fluidized bed airstream micronizing machineWorking Princible After the material enters the crushing chamber, it becomes fluidized under the action of the centripetal countercurrent jet field formed by the high-speed compressed jet. The accelerated material converges at the intersection point of multiple nozzles, generating severe impact, collision, and friction, resulting in crushing. The crushed fine powder moves upward with the airflow into the upper grading chamber. Due to the high-speed rotation of the grading wheel, under the action of centrifugal force, the coarse powder returns to the crushing chamber for further crushing. The fine powder that meets the fineness requirements is discharged from the exhaust port and enters the cyclone separator and dust collector for collection. The dusty gas undergoes gas-solid separation in the dust collector, and the gas is exhausted by the induced draft fan.

Performance & Characteristics Low energy consumption, compared with traditional fluidized bed jet crushers, it can save 30% of energy. Since the material in the crushing chamber mainly collides with each other, and rarely collides with the inner cavity of the crushing main engine, there is little pollution to the material, which can produce high-purity materials. Built-in self-diverging micro-powder grader, with a concentrated particle size distribution and no oversized particles in the finished product. Low-temperature medium-free crushing, especially suitable for the crushing of low melting point, thermosensitive, sugar-containing, and volatile materials. For flammable and explosive materials, inert gas can be used as a medium to achieve fully enclosed crushing. The inert gas is recycled with low loss. Automatic control capability, convenient operation. Scope of Application Widely used in industries such as chemical, mining, abrasives, refractory materials, battery materials, metallurgy, building materials, pharmaceuticals, ceramics, food, pesticides, feed, new materials, environmental protection, and various dry powder materials for ultra-fine crushing, dispersing, and particle shaping.

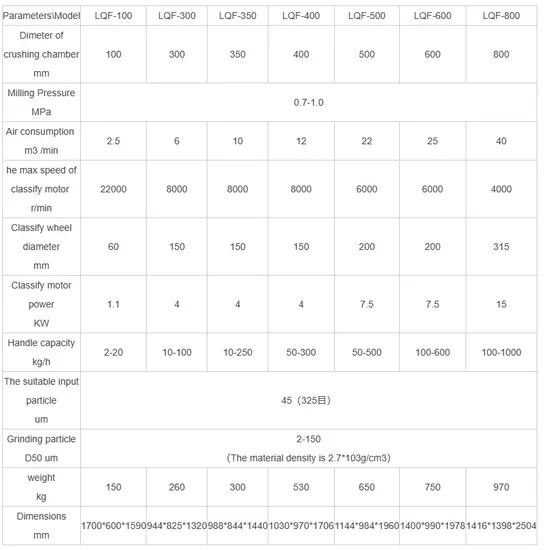

Product Parameters

Detailed Photos

Our Factory Production Line

>> Swimwear Sportswear Short Stretch Beach Shorts

>> SHENGKE Elegant Fashion Gifts For Women Stainless Steel Mesh Band Quartz Movement Ladies Watches K0029L Reloj Para Mujer

>> knives for Sewing Machinery -03

>> 175mm Full Tooth Diamond Wheel with Customization Assistance in Us$

>> Automatic donut machine donught making machine commerical mini donut fryer machine

>> Advanced 244 Cylinder Type Automatic Oil Supply Sewing Machine

>> 40ton Crane Water Weight Bags Load Testing

>> blank high quality hoodies wholesale custom logo hoodie manufacturers fleece fabric oversized men hoodie

>> Precision CNC Milling Machine V11, Customizable, Fanuc Technology

>> 9179 cheap fancy watch Skmei latest watches design for ladies minimalism high quality leather hour time couple watches

>> Guangzhou Diseng Computerized Cap Flat 6 Head 9/12/15 Needles Embroidery Monogramming Industrial Embroidery Sewing Machine Price

>> JIMBO China Professional Manufacture Hidden Electronic Finger Print jewelry gun safe

>> Solid wood main entrance door design oil painted, waterproof & mositure proof

>> Automatic H Type Poultry Cage Layer Chicken Battery Cages

>> Japan Yamarine 40HP Outboard Motor & Engine Replace YAMAHA E40X, E40g, E40j

>> For BMW 5 Series G30 change to FD style Carbon Fiber Rear Carbon Lip bumper body kit other parts

>> China Manufacture Biomass Softwood Sawdust Pellet Mill Line Price Coarse Fibre Pelletizing Use Pellet Mill

>> Escalator Rubber Roller Wheel in China

>> Rubber Kneader Machine Automatic Chemical Dosing Machine/Rubber Kneader Mixer Machine Automatic Weighing Machine

>> Sublimated Vest Customized 100% polyester Made.

>> Symbolic Marble Virgin Mary Statue Religious Sculpture for Faithful Reflection

>> Double Wheel Russia Wb6418s Wheelbarrow for Construction and Garden

>> Multi Crops Paddy Wheat Grain Low Fuel Consumption Machine Small Combine Rice Harvester with Straw Bale

>> lovely Flower Jewelry Box Velvet wedding Ring box Necklace Display Gift box Container Case for Jewelry Packaging

>> Xinya 250W 300W CE Approved 220V Clean Water Russia Electric Vibration Pump Submersible Pump (VMP60-1)

>> W8X24 Agricultural/Farm Wheel for Middle East and All Over The World

>> Custom Sports Wear Quick Dry Moisture Sports Men Fitness Gym T-Shirts

>> Tbhd1250 Drilling and Milling Machine for Beam and Channels

>> Beautiful Lantern Decoration for Festival and Activity Handmade Silk Lantern

>> 6*1 /3.5*25mm C1022 Bugle Head Black/Grey Phosphated/Zinc Plated/Fine/Coarse Thread Gypsum Screw/Drywall Screw