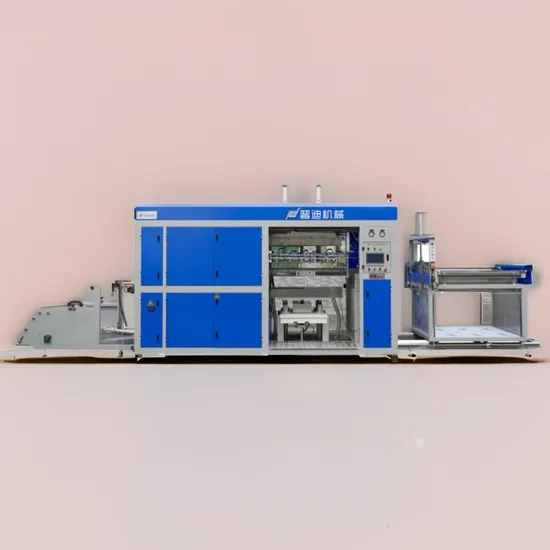

Factory Price Small Automatic Thick Vacuum Forming Machine Shell Drone Cover

| US$30,000.00-50,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

PDVF-XS710

Shaping Mode

Die Molding

Driven Type

Electric

Computerized

Computerized

After-sales Service

1 Year

Color

Blue

Customs Code

8477409000

Output

200PCS/Year

Transport Package

Simple Packaging or Wooden Crates

Specification

Forming area: 7700mm*1600mm

Trademark

PUDI

Origin

Dongguan

HS Code

8477409000

Production Capacity

200PCS/Year

Product Description

Product DescriptionParameters.

Parameters of PDVF-XS710 Vacuum Forming Machine (Single Electric Furnace)

| NO. | Name | Specification |

| 1 | Molding method | Vacuum forming |

| 2 | Molding size | Forming length:500mm-1220mm Forming width:450mm-710mm |

| 3 | Molding depth | ≤150mm |

| 4 | Material and thickness | PVC,PET,PS,PP etc. 0.15mm-2.0mm |

| 5 | Loading system | Motor automatic loading, can load 150KG a roll of material. |

| 6 | Heating systems | Heat furnace using energy-saving 600W heating bricks 60 pieces |

| 7 | temperature control systems | "AOYI" temperature control module, one-to-one control, fast heating and fast adjustment. |

| 8 | pulling systems | 3KW Delta servo motor pull tab |

| 9 | Molding Systems | The upper and lower molds adopt Taiwan "Delta" 4.5KW servo motor |

| 10 | cooling systems | 12 meiji automatic spray guns ;four powerful double-head fans |

| 11 | control system | MCGS 10-inch color touch screen ; PLC:Taiwan "Delta" |

| 12 | Pneumatic Components | Water-oil separator, solenoid valve: Japan "CKD" Two way solenoid valves: Italian ceme |

| 13 | electronic component | Contactor: Japan Fuji Relay: Japan Izumi |

| 14 | guideway | Light flat water transport guide, hard chrome plated surface, motorized width adjustment |

| 15 | vacuum system | a 160m³ vacuum pump of brand Busch; Vacuum storage tank 0.4m³ |

| 16 | chiller | One 3HP of Taiwan Tengfei |

| 17 | memory function | Capable of storing production data for 100 groups of products |

| 18 | Silicone oil spraying system | 2 additional spray guns front and rear for silicone lubrication |

| 19 | Rack Body | 100mm*100mm square tube ,Furnace Retrofit Doors |

| 20 | Size of the whole machine | Length:7700mm Width:1600mm Height:2500mm |

| 21 | power supply | Power: Maximum 50KW Normal production 25KW-35KW Voltage: 380V 50HZ |

| 22 | air supply | 10HP air compressor, air pressure 6-8bar (self-contained) |

Product Description

PD-XS710 Automatic Blister Moulding Machine

Use for below products:

Detailed drawing of the machine

About shipping to loading container

The overview of PD-XS710

A.PD-XS710 vacuum suction servo molding machine, using microcomputer and industrial control programmable PLC control, the whole system HMI (human-machine interface). Using Chinese and English interface (can be customized in other languages), the machine has including button operation and all process parameters set and modify, so that the equipment is easy to operate and maintain.

B. Usage: It is suitable for molding plastic sheets such as HIPS, PS, PP, PVC, APET, PETG, etc. Processing high transparent, high stretch, shallow stretch, round, square, irregular, up and down bi-directional stretching, flanging and other products. Produce all kinds of food packaging, medical packaging, toy packaging, industrial packaging and other packaging products.

C. Machine body: welded or spliced with steel structure profiles, the overall steel structure frame has enough strength and rigidity. All metal surfaces are treated with antirust treatment and bottom sprayed with antirust paint; common and standardized parts are used in the structure, which is convenient for maintenance and replacement of all parts in the later stage.

D. The whole machine is divided into manual/automatic mode, all setup operations are realized on the touch screen; when the operator places the material well, press the automatic startup equipment to complete the whole process of molding technology once, manual is mainly used for mold changing or sample starting control.

Features of PD-XS710

1.This machine is controlled by PLC, and all functions can be operated in touch screen.

2.Pulling piece adopts servo motor control, can adjust different speed or length, faster, accurate, stable, and at the same time with material exit function, to avoid material waste.

3.Mold table lifting is driven by servo motor, can be independently divided into rising and falling, to meet the different heights of products, to the fastest speed production.

4.The electric furnace adopts voltage temperature control, which makes the temperature more moderate and easy to control, and the power consumption is low.

5.Built-in water transportation cooling system with chiller cabinet cooling molding, at the same time with heat insulation board, beam water transportation, more quickly.

6.Equipped with product counting function

7.Production efficiency is about 20s cycle.

8.PLC program has set up 100 groups of memory system, the user can download the parameters of production in the memory file, to be repeated when the production is taken out to use, convenient, time-saving.

9.Product cooling is air-cooled and spray cooling, which can be chosen at will.

10.mold change time is very short, 5-10 minutes.

OUR EXPERTISE ,YOUR ADVANTANGE

1.Professional Technical Team :20 years of R&D and production experience,with rich experience in vacuum moulding technology

2.Non-standard customised service : Provide one-stop service to provide customers with excellent complete vacuum forming solutions .

3.Quality assurance and reliability : All mechanical parts are produced independently by CNC machining centre

4.Worry free after-sales service : Integration of installation ,commissioning and training services

Pudi service standard

Pre-sales service

1. According to the customer's products to provide customers with a reasonable program, plastic absorbing machine and peripheral equipment investment ratio.

2. Provide the amount of water, electricity and gas needed for the production workshop.

3. Provide reasonable workshop planning program.

4.Provide the mold manufacturers and material manufacturers for plastic injection molding.

The sale of services

1. In order to improve the subsequent production efficiency of the customer, the customer's existing molds or re-development of the mold planning proposals.

2. After the completion of the production of equipment, responsible for the installation, commissioning, training. And assist the operator to produce the ideal products.

3. Provide good production suggestions to customers who have just entered the plastic absorbing industry, and reduce customers' production costs.

After-sales service

1. One year warranty for the whole equipment, and the parts can be exchanged for new ones within one year (except for man-made damages and wearing parts).

2. Lifetime maintenance of the equipment, after the warranty period only charge the cost of materials, such as the need for door-to-door service only charge a reasonable travel expenses.

3. For all the customers who have purchased Pudi's equipment, we will make after-sale visits from time to time.

We can customise any model, if you are interested in our machines, please feel free to contact me!

>> Nordic Designer Decoration Glass Shade Marble Base Under Table Lights Reading Lamp

>> Food Kraft V Sharp Bottom Shopping Carry Paper Bag Making Machine

>> Cotton Candy Floss Machine for Sale Commercial / Flower Cotton Candy Maker

>> Eaton Solenoid Valve DG4V-3-8C-VM-U-H7-61 KBDG5V-8-33C330N-M2-PE7-H1-10 KBFDG5V-5-2C95N-X-M1-PE7-H1-10 DG4V-5-2N-M-U-C6-20

>> Nat Routing Port Router for Industrial Use

>> High Speed Furniture Edge Banding Machine for PVC

>> Auto Resistor Iridium Platinum Bujias Spark plugs 2756 BKR6E-11 For Chevrolet Aveo

>> Motorcycle Engine Parts Motorcycle Cylinder (piston, piston rings) for Pulsar 200ns

>> Stainless Steel Full Bore/Flow Control/Non-Retention Factory Supply Flange Gate Valve for Water/Air/Oil/Gas/Liquid

>> Travel New Baby Electric Fan DC USB Powered 3 Wind Speeds Adjust Handy Pocket Fan Portable Mini Hand Held Rechargeable Fan

>> 4m - 24m Aluminum Alloy Mast Lifting Aerial Work Platform Home Lifter Single Person Lifting Platform

>> Factory Supplies Disposable Baby Diapers, Super Soft and Suitable for Babies Skin

>> Deodorant Stick Deodorant Containers

>> Stylish Mechanical Shell Stitch Sewing Machine with Automatic Oil Supply

>> Truck Parts Car Parts Auto Accessory Drive Shaft Center Support Bearing

>> CE EPA High Performance Household Hydraulic Small Mini Crawler Digger

>> Factory Price 304 201 Mirror No. 8 No. 4 Stainless Steel Sheet Plate with Good Quality

>> 22003 Sweetheart Necklitne Lace Wedding Dress with Long Train A-Line Tulle Skirt Foreign Trade Simple Bridal Wedding Gown Dress with Factory Wholesale

>> High Quality Textile High Temperature Dyeing Machine

>> Used Second Hand Cat320d Excavator

>> Bamboo wood salad mixing bowl serving wooden salad bowl set

>> Burnt Ostrich Feather Plume Dyed Green from China

>> Commercial Use Popcorn Machine/Popcorn maker/Popcorn making machine

>> 500lph Water Filter System RO Reverse Osmosis Water Treatment Machine System Drinking Water Purifier Water Treatment Equipment Plant

>> Indoor Playground Equipment Amusement Park Kids Play Area Indoor Customized by Cheer Amusement

>> China High Quality Stone Crushing Equipment Impact Crusher Machine for Concrete Granite Crushing

>> Hot Sale 100-800kw Pig/Cow/Chicken Farm Biogas Generator

>> Construction Elevator 2t/2t Double Cages Building Hoist

>> U2 Universal Tool Grinder with Roller Sharp Carbide-Tipped Cut-off Turning Tool Blade

>> OEM/ODM R410 T1 T3 Air Conditioner Inverter 24000 Btu