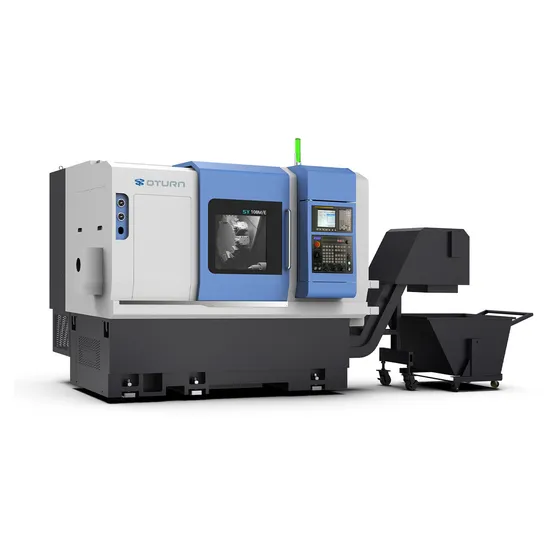

Oturncnc 3 Axis Slant CNC Turning Milling Center Turret Lathe for Precision Auto Parts

| US$28,500.00-182,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

ESY108M

Type

Turret Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Electric

Controlling Mode

CNC

Automatic Grade

Automatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, ISO 9001

Condition

New

Control System

Fanuc, Siemens, Mitsubishi

Spindle

A2-6,A2-8,A2-11

Chuck

6,8,10,12inch

Tool Turret

Vdi or Bmt

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

2400x2000x1900

Trademark

Oturn

Origin

China

HS Code

8458110090

Production Capacity

1000/Year

Product Description

Product Description

Experience unparalleled efficiency and precision with our state-of-the-art two-axis lathe. Designed to process both ends of the workpiece simultaneously in a single clamping, this machine streamlines manual operations, boosts output, and minimizes procedural steps. Featuring a secondary spindle for comprehensive turning and efficient workpiece transfer, cycle times are drastically reduced. The 30-degree inclined structure design ensures high precision, superb rigidity, and exceptional cutting stability. Crafted from one-piece high-strength HT300 cast iron and employing finite element analysis, the robust lathe bed delivers outstanding mechanical rigidity and stability for long-term accuracy. The machine's high-strength roller linear rail structure and screw pre-tension transmission system enhance rigidity performance. Its simple yet elegant appearance reflects modern design trends, ensuring both functionality and aesthetics.

Main Features of This Machine Tool:

1. Our advanced direct drive synchronous electric spindle device offers remarkable precision with a magnetic ring incremental encoder (sine and cosine) positioning accuracy of 20 arc seconds and C-axis indexing accuracy of 40 arc seconds. This design effectively eliminates spindle vibration, maintaining a nose deflection accuracy within 0.002MM, thus improving the surface finish of workpieces. The rear-mounted rotor simplifies installation and maintenance, while the spindle motor's integrated cooling system mitigates thermal displacement, ensuring a constant operating temperature. Undergoing rigorous dynamic balance testing, the spindle system ensures superior accuracy retention, rigidity, and efficiency, making it ideal for mass production of complex shapes requiring high smoothness, from finishing to rough machining and heavy cutting.

2. Featuring a high-rigidity integrated design, the servo power turret enhances rapid and precise tool changing performance. Coupled with high-speed power axis milling, it delivers excellent turning and milling combined processing capabilities. The tool holder benefits from a high-rigidity BMT installation interface, with the power transmission shaft driven by a servo spindle motor for optimal performance.

3. Equipped with roller linear guides and ball screws, our machine tool ensures peak accuracy and durability. The heat-treated and precision-ground ball screws maintain accuracy under all conditions. Each axis employs a direct transfer structure and double-anchor pre-relay method to minimize thermal displacement, significantly boosting processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails sustain accuracy even under impact, with smooth, low-noise displacement that extends service life.

4. Our machine features a comprehensive hydraulic and lubrication system, utilizing top-quality hydraulic pumps, valves, and components to minimize failure rates. These systems are designed for simplicity and reliability, ensuring seamless operation.

5. The inclusion of a Taiwan rotary chuck cylinder and an optional automatic chip removal device significantly reduces operator labor intensity, promoting safe and efficient production. Programmable functional components allow for customization to meet special user requirements, enhancing versatility and productivity.special fixture.

Product Parameters

| Item | Unit | SY108M/E |

| Max. swing diameter over bed | mm | Φ600 |

| Max. processing diameter | mm | Φ300 |

| Max. processing diameter over tool holder | mm | Φ200 |

| Max. processing length | mm | 300 |

| Distance between centers | mm | 450 |

| Spindle type | type | A2-6 |

| Max. spindle speed | rpm | 4300 |

| Hydraulic Cylinder/ Chuck | lnch | 8″ |

| Spindle bore diameter | mm | Φ65 |

| Max. bar diameter | mm | Φ52 |

| Direct drive spindle motor power | kw | 18/22 |

| X axis travel | mm | 170 |

| Z axis travel | mm | 320 |

| X/Z axis rail specifications | spes | Roller35 |

| X/Z axis motor power | kw | 2.4 |

| X/Z axis rapid speed | m/min | 30 |

| X/Z axis positioning accuracy | mm | ±0.005 |

| X/Z axis repeatability | mm | ±0.003 |

| Power turret type | pcs | BMT45-12T |

| Power turret motor | KW | 4 |

| Max. power tool holder speed | rpm | 5000 |

| External diameter tool holder specification | mm | 25X25 |

| Internal diameter tool holder specification | mm | Φ40 |

| Adjacent tool change time | sec | 0.15 |

| Positioning accuracy | / | ±2" |

| Repeatability | / | ±1" |

| Hydraulic tailstock | / | Programmable |

| Max. Tailstock travel | mm | 360 |

| Tailstock sleeve tapered hole | type | Mohs4# |

| Sleeve diameter | mm | 80 |

| Sleeve travel | mm | 100 |

| Machine size | mm | 2400x2000x1900 |

| Machine weight | kg | 3800 |

| Cutting fluid tank volume | L | 150 |

| Hydraulic unit box volume | L | 40 |

| Hydraulic pump motor power | kw | 1.5 |

| Lubricat tank volume | L | 2 |

| Automatic lubrication pump motor power | W | 50 |

| Coolant water pump power | W | 750 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1: How can I choose the most suitable machines?

Please provide your specifications, and we will recommend the best model for you. Alternatively, you can select the exact model, or send us your product drawings, and we will ensure you get the most suitable machine.

Q2: What are the main products of your company?

We specialize in a diverse range of machinery, including CNC Lathe Machines, CNC Milling Machines, CNC Turning Machines, Vertical Machining Centers, Horizontal Machining Centers, Lathe Machines, and composite processing machines for turning and milling.

Q3: Where is your factory located, and how can I visit?

We have five factories situated in Guangzhou, Quzhou, Ningbo, and Guangdong. You are warmly welcome to visit us.

Q4: How do you transport the machines?

We offer comprehensive transportation solutions including DDP, CIF, FOB, and FCA.

Q5: What are the Payment Terms?

We accept T/T payments with a 30% initial deposit upon order and the remaining 70% before shipment.

Q6: What's the Minimum Order Quantity (MoQ)?

A: The MoQ is 1 set. Only certain low-cost machines require more than 1 set.

We need to know:

1. We strongly suggest you provide the size and material of your workpiece for our evaluation. If possible, send us the workpiece drawing so that we can recommend the most suitable model!

2. If you need a CIF Price, please kindly inform us of the port of destination.

>> Wired Magnetic Door Sensor / Contact Magnetic Door Alarm Switch

>> Wholesale Low MOQ Trolley Bags Travel Spinner Luggage Set for Business Trip

>> K2 Three Ways Line Array Professional Audio Speaker with Loudspeaker

>> Promotion Gift Custom Carnival Full Color Stamped Metal Souvenirs/Emblem/Police/Lapel Pin/Military Badge

>> Daying Xindai 35° Inclined Bed Knife Setting Machine Ck6125

>> New Arrival Office Gaming Lightweight Wireless Bluetooth Mouse Agent

>> High Speed Preform Pet Bottle Making Water Beverage Container Molding Injection Machine

>> Offroad Sports Roll Bar Rack Bed Bar for F-ord Ranger 2015+ Truck Roll Bar Pickup

>> Hot Sell Educational Kid Children Toy Juguete Family Table Toy Wooden Number Toy Baby Toy Funny Interactive Game Toy Drinking Novelty Toy

>> aluminium sliding window price balcony residential double glazed aluminum slide windows resistant

>> Round Counter Top Ceramic Basin with Chaozhou Bathroom Sink Modern Sanitary Ware

>> CNC Turning Center Machine Dual-Spindle Automation

>> Gift Watches 2 in 1 Wireless Smartwatch Heart Rate Monitor Music Headphones Fashion Bluetooth Smart Watch

>> Customized Carbon Steel Hard Chrome Plated ISO F7/G6 Quenching and Tempering Chrome Shaft for Hydraulic Cylinder Piston Rod

>> Servo Motor PLC Controller Toroidal Transformer Core Coil Winding Machine with Touch Screen for Electronic Components Autotransformer

>> Excellent goods flax seed cold oil press machine/sunflower seeds oil extract machine/soybean oil making machine

>> Pch1221 / Krc1221 Coarse Coal Crusher with Ring Hammer Discharge Size 30mm

>> 2.5HP Agricultural Power Tiller Gasoline Garden Tiller Mini Tiller (TM-WG520D)

>> Straight Women′s Headband Wig Malaysian Human Hair Wig Straight Non Lace Scarf Wigs Glueless Natural Hair Wig for Female

>> Plastic foam crushing hot melting block making machine Waste Foam thermal melting tuo Machine

>> Mining Applications Durable PF Series Hard Rock Impact Crusher

>> Chery Jetour Shanhai T2 New Energy Vehicles China Distributors Rhd European Version Electric Car EV Vehicle 5-Door 5-Seater SUV Hybrid SUV Vehicles Hot Selling

>> Zy-T3 Zoyer Straight Knife Auto-Sharpening Cutting Machine

>> Auto Linear Tool Change Woodworking Nesting CNC Router High Speed Carving 1325 Atc Wood Engraving Machine

>> Custom Camping Net Hammock Outdoor Traveling Anti-Mosquito Hiking Hammock Camp Tent Hammomck Nylon Portable Multicolor Hammock Durable Hammock

>> Professional Abrasive Sand Impact Crusher

>> 250ml Factory Price Tube Parallel Synthesis Reactor

>> Main Power 2*4.4kw CNC Hydraulic System Synchronous Press Brake

>> high Quality Fabric sale heavy weight jiu jitsu gi suits with rash guard kimono for judo uniform

>> Manufacturer carton cardboard box packaging custom design corrugated Kraft Paper Box