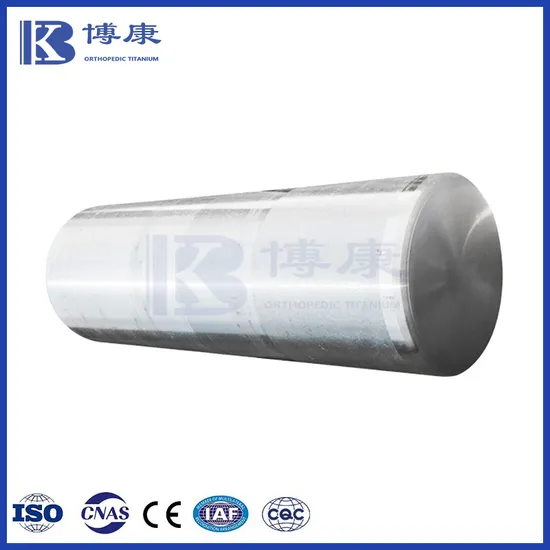

Medical Aerospace Industrial Grade 5 Ti-6al-4V Titanium Alloy Ingot

| US$11.00-21.00 | 1,000 kg (MOQ) |

Basic Info.

Model NO.

BKTI

Technique

Var Melting+Machining

Grade

Gr1,Gr2,Gr3,Gr4,Gr5,Gr9,Gr23

Shape

Round

Material

Ta6V Titanium Alloy

Color

Silver

Surface Treatment

Machining

Standard

ASTM, ISO, AMS, JIS, DIN

Melting Times

Triple

Diameter (mm)

380, 480, 580, 620, 720

Weight(T)

1t, 1.5t, 2.5t, 5t

Mnq

1t

Sample

Available

ODM & OEM

Acceptable

Transport Package

Wood Case

Trademark

Bokang

Origin

Changzhou, China

HS Code

8108901090

Production Capacity

200tons/Year

Product Description

Product Description Titanium Ingot (Ti Ingot) Description:Our titanium ingots are made from high-purity sponge titanium and premium intermediate alloys. After precise mixing and pressing, they are welded using advanced vacuum electron beam welding to prevent the introduction of impurities. The ingots then undergo three rounds of VAR (Vacuum Arc Remelting) to increase purity and reduce impurity elements, resulting in uniformly composed titanium ingots. Common specifications include 380, 480, 580, and 620. Titanium Ingot offers a robust and reliable solution for various industrial applications.

Titanium Ingot (Ti Ingot) Specifications

| Product Name | Titanium Ingots |

| Material Grade | Gr1,Gr2,Gr2H,Gr3,Gr4,Gr5,Gr7, Gr9,Gr11,Gr12,Gr16,Gr23,Gr29, Ti-6Al-2Sn-4Zr-2Mo, Ti-5Al-5V-5Mo-3Cr,etc |

| Diameter (mm) | Φ380, 480, 580, 620, 720 |

| Weight(T) | 1T,1.5T,2.5T, 2.5T, 5T |

| Standard | ASTM B977;ASTM F67;ASTM F136; ISO5832-2;ISO5832-3;AMS4928;AMS4965;AMS4967;ASTM B348; ASTM B863 |

| Melting times | Triple |

Impurities Content:

| Grade | Element Impurities, not more than(%) | ||||

| Fe | C | N | H | O | |

| Gr1,Gr2,Gr3,Gr4 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 |

| Ti-6Al-4V Eli | 0.25 | 0.08 | 0.03 | 0.012 | 0.13 |

Titanium Ingot Production Process:

Sponge Titanium→Compacting Electrodes→Electrode Welding→Triple VAR Melting→Packaging→Delivery

Applications of Titanium Ingot

Titanium ingots are the raw material for forgings, rings, tubes, and profiles.

1. Medical: Titanium Ingot is also used in a wide range of medical applications. Due to its biocompatibility and corrosion resistance, Titanium Ingot is often used in the manufacture of medical devices such as scalpels, operating tables, and artificial joints. It is also used in areas such as dentistry and orthopedics.

2. Aerospace: Titanium Ingot has a wide range of applications in the aerospace sector. It is used to manufacture aircraft components such as fuselages, wings, and engine parts. Due to its lightweight and high-strength properties, Titanium Ingot helps to reduce the weight of aircraft, improve fuel efficiency, and ensure flight safety.

3. Automotive manufacturing: Titanium Ingot is also widely used in automotive manufacturing. It is used to manufacture automotive components such as engine parts, exhaust systems, suspension systems, etc. These components need to withstand high temperatures and corrosion. These parts need to withstand high temperatures and corrosion, and Titanium Ingot's resistance to corrosion and high temperatures makes it an ideal material choice.

4. Chemical industry: In the chemical industry, Titanium Ingot is widely used in the manufacture of equipment such as chemical reactors, heat exchangers, and pipes. Due to its corrosion resistance and high-temperature tolerance, Titanium Ingot can withstand the corrosion of various chemicals and high-temperature environments to ensure the long-term stable operation of chemical equipment.

Chemical Composition Chemical Composition

ASTM B977 Chemical Requirements:

| Grade | UNS NO. | C max | O range or max | N max | H max | Fe range or max | Al | V | Pd | Ru | Ni | Mo | Cr | Co | Zr | Nb | Sn | Si | Other Elements,max,each | Other Elements,max,total |

| 1 | R50250 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 2 | R50400 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 3 | R50550 | 0.08 | 0.35 | 0.05 | 0.003 | 0.30 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 4 | R50700 | 0.08 | 0.40 | 0.05 | 0.003 | 0.50 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 5 | R50400 | 0.08 | 0.20 | 0.05 | 0.003 | 0.40 | 5.5-6.75 | 3.5-4.5 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 6 | R54520 | 0.08 | 0.20 | 0.03 | 0.003 | 0.50 | 4.0-6.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 2.0-3.0 | ... | 0.1 | 0.4 |

| 7 | R52400 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.12-0.25 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 9 | R56320 | 0.08 | 0.15 | 0.03 | 0.003 | 0.25 | 2.5-3.5 | 2.0-3.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 11 | R52250 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | 0.12-0.25 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 12 | R53400 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | ... | ... | 0.6-0.9 | 0.2-0.4 | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 13 | R53413 | 0.08 | 0.10 | 0.03 | 0.003 | 0.20 | ... | ... | ... | 0.04-0.06 | 0.4-0.6 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 14 | R53414 | 0.08 | 0.15 | 0.03 | 0.003 | 0.30 | ... | ... | ... | 0.04-0.06 | 0.4-0.6 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 15 | R53415 | 0.08 | 0.25 | 0.05 | 0.003 | 0.30 | ... | ... | ... | 0.04-0.06 | 0.4-0.6 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 16 | R52402 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 17 | R52252 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 18 | R56322 | 0.08 | 0.15 | 0.03 | 0.003 | 0.25 | 2.5-3.5 | 2.0-3.0 | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 19 | R58640 | 0.08 | 0.12 | 0.03 | 0.003 | 0.30 | 3.0-4.0 | 7.5-8.5 | ... | ... | ... | 3.5-4.5 | 5.5-6.5 | ... | 3.5-4.5 | ... | ... | ... | 0.15 | 0.4 |

| 20 | R58645 | 0.08 | 0.12 | 0.03 | 0.003 | 0.30 | 3.0-4.0 | 7.5-8.5 | 0.04-0.08 | ... | ... | 3.5-4.5 | 5.5-6.5 | ... | 3.5-4.5 | ... | ... | ... | 0.15 | 0.4 |

| 21 | R58210 | 0.08 | 0.17 | 0.03 | 0.003 | 0.40 | 2.5-3.5 | ... | ... | ... | ... | 14.0-16.0 | ... | ... | ... | 2.2-3.2 | ... | 0.15-0.25 | 0.1 | 0.4 |

| 23 | R56407 | 0.08 | 0.13 | 0.03 | 0.003 | 0.25 | 5.5-6.5 | 3.5-4.5 | 0.1 | 0.4 | ||||||||||

| 24 | R56405 | 0.08 | 0.20 | 0.03 | 0.003 | 0.40 | 5.5-6.75 | 3.5-4.5 | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 25 | R56403 | 0.08 | 0.20 | 0.03 | 0.003 | 0.40 | 5.5-6.75 | 3.5-4.5 | 0.04-0.08 | ... | 0.3-0.8 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 26 | R56404 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 27 | R52254 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 28 | R56323 | 0.08 | 0.15 | 0.03 | 0.003 | 0.25 | 2.5-3.5 | 2.0-3.0 | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 29 | R56404 | 0.08 | 0.13 | 0.03 | 0.003 | 0.25 | 5.5-6.5 | 3.5-4.5 | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 30 | R53530 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | 0.20-0.80 | ... | ... | ... | ... | 0.1 | 0.4 |

| 31 | R53532 | 0.08 | 0.35 | 0.05 | 0.003 | 0.30 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | 0.20-0.80 | ... | ... | ... | ... | 0.1 | 0.4 |

| 32 | R55111 | 0.08 | 0.11 | 0.03 | 0.003 | 0.25 | 4.5-5.5 | 0.6-1.4 | ... | ... | ... | 0.6-1.2 | ... | 0.6-1.4 | ... | ... | 0.6-1.4 | 0.06-0.14 | 0.1 | 0.4 |

| 33 | R53442 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.01-0.02 | 0.02-0.04 | 0.35-0.55 | ... | 0.1-0.2 | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 34 | R53445 | 0.08 | 0.35 | 0.05 | 0.003 | 0.30 | ... | ... | 0.01-0.02 | 0.02-0.04 | 0.35-0.55 | ... | 0.1-0.2 | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 35 | R56340 | 0.08 | 0.25 | 0.05 | 0.003 | 0.20-0.80 | 4.0-5.0 | 1.1-2.1 | ... | ... | ... | 1.5-2.5 | ... | ... | ... | ... | ... | 0.20-0.40 | 0.1 | 0.4 |

| 36 | R58450 | 0.08 | 0.16 | 0.03 | 0.001 | 0.03 | ... | ... | ... | ... | ... | ... | ... | ... | 42.0-47.0 | ... | ... | ... | 0.1 | 0.4 |

| 37 | R52815 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | 1.0-2.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 38 | R54250 | 0.08 | 0.20-0.30 | 0.03 | 0.003 | 1.2-1.8 | 3.5-4.5 | 2.0-3.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 39 | R53390 | 0.08 | 0.15 | 0.03 | 0.015 | 0.15-0.40 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.30-0.50 | 0.1 | 0.4 |

| 42 | R53475 | 0.08 | 0.25 | 0.05 | 0.003 | 0.30 | ... | ... | ... | ... | 0.1-1.0 | 3.0-4.5 | ... | 0.1-1.5 | ... | ... | ... | 0-0.50 | 0.1 | 0.4 |

Analysis Tolerances

ASTM B977 Analysis Tolerances:

| Element | Product Analysis Limits, max or Range, % | Permissible Variation in Product Analysis |

| Aluminum | 0.5 to 2.5 | ±0.20 |

| Aluminum | 2.5 to 6.75 | ±0.40 |

| Carbon | 0.1 | ±0.02 |

| Chromium | 0.1 to 0.2 | ±0.02 |

| Chromium | 5.5 to 6.5 | ±0.30 |

| Cobalt | 0.2 to 0.8 | ±0.05 |

| Hydrogen | 0.02 | ±0.002 |

| Iron | 0.80 | ±0.15 |

| Iron | 1.20 to 1.8 | ±0.20 |

| Molybdenum | 0.20 to 0.4 | ±0.03 |

| Molybdenum | 0.60 to 1.2 | ±0.15 |

| Molybdenum | 1.50 to 4.5 | ±0.20 |

| Molybdenum | 14.0 to 16.0 | ±0.50 |

| Nickel | 0.3 to 0.9 | ±0.05 |

| Niobium | 2.2 to 3.2 | ±0.15 |

| Niobium | >30 | ±0.50 |

| Nitrogen | 0.05 | ±0.02 |

| Oxygen | 0.30 | ±0.03 |

| Oxygen | 0.31 to 0.40 | ±0.04 |

| Palladium | 0.01 to 0.02 | ±0.002 |

| Palladium | 0.04 to 0.08 | ±0.005 |

| Palladium | 0.12 to 0.25 | ±0.02 |

| Ruthenium | 0.02 to 0.04 | ±0.005 |

| Ruthenium | 0.04 to 0.06 | ±0.005 |

| Ruthenium | 0.08 to 0.14 | ±0.01 |

| Silicon | 0.06 to 0.40 | ±0.02 |

| Tin | 0.62 to 3.0 | ±0.15 |

| Vanadium | 0.6 to 4.5 | ±0.15 |

| Vanadium | 7.5 to 8.5 | ±0.40 |

| Zirconium | 0.6 to 1.4 | ±0.15 |

| Zirconium | 3.5 to 4.5 | ±0.20 |

| Residuals (each) | 0.15 | 0.02 |

Titanium Ingots Tolerances:

| Diameter (mm) | ≤350 | >350~550 | >550~720 | >720~820 | >820~1040 | >1040 |

| Tolerance | +5 -30 | +5 -40 | +5 -60 | +5 -70 | +5 -80 | +5 -100 |

| Titanium Bar/Rod | Titanium Wire | Titanium Disc |

| Titanium Ingot | Nitinol/Nickel Titanium | Artificial Joint Castings |

About Bokang

Our Advantages

FAQ Q: Are you a direct manufacturer or trading company?

A: We're a manufacturer with more than 18 years of professional production experience.

Q: Do you offer free samples?

A: Usually, our sample is free but we need our customer to pay the freight.

Q: What is the minimum quantity per order?

A: 1 kg. For regular standard medical and aerospace materials, based on our production capacity of 20 tons per month for titanium wire and rods. the stock inventory could meet all your requirements.

Q: What products can you offer?

A: We specialize in the production of pure titanium, titanium alloy, titanium rods, wires, discs, nitinol alloy, etc.,

Q: What's the payment term?

A: When we quote for you, we will confirm with you the way of transaction, FOB, CIF, CNF, etc.

For mass-production goods, you need to pay 30% deposit before producing and 70% balance against a copy of documents. The common way is by T/T. L/C is also acceptable.

Q: What applications do your products relate to?

A: Our titanium alloys and nitinol alloys are widely used in medical, aerospace, and other Industries.

Q: How can we get your price?

A: We need the below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

Q: Can you do customized products?

A: Yes, we support customized products according to the customers' drawings or samples.

Q: How do you guarantee the quality of your goods?

A: We ensure quality by inspecting every process and using advanced testing equipment to conduct comprehensive checks, ensuring finished products meet customer and international standards.

Q: How do you deliver the goods to us?

A: We will usually ship the goods by sea and air according to your requirements.

>> Ak36 Servo Nc Lathe Turret

>> Jiangsu Wewoo Big Gantry Machining Center Gmc2016 Heavy Gantry Milling Machine

>> Custom Made Modern Laboratory Nonwoven Disposable Shoe Cover

>> EL200 High Precision Fanuc System CNC Lathe Goodway CNC Lathe Machine

>> 10L Dual Jacketed Glass Reactor Glass Reactor Stirrer Glass Reactor for Lab

>> High-Precision Double Spindle CNC Lathe with Integrated Box Structure Ety200msy

>> Modern Office Furniture Wooden Filing Cabinets with Glass Door (CAS-FA33)

>> Manufacture Decorative Aluminum Facade Mesh Expanded Metal Mesh in China

>> Metal Iron Sheet Lock Former Machine/Pittsburgh Locker for Plate Linkage

>> Titanium Carbide Cermet Rod for Stone Machines Crusher Replacement Casting Foundry

>> Plastic Wall Panels Decorative Interior high Strength Decorative PVC Wall Panel

>> Wholesale Pigeon Food Machine Ring Die Pellet Mill

>> 30W 50W 100W 3D 2.5D Portable Mini CNC Metal Plastic Fiber UV CO2 Mopa Fiber Laser Marking Printing Deep Jewelry Engraving Machine

>> China Best 1K/2K Solid Colors/Pearl/Metalic Car Paint

>> Mini Car Cleaning Tools Dustpan Brush

>> Faux Synthetic PU Artificial Sofa Leather Similiar to Genuine Leather for Upholstery Furniture Boxing Fitness

>> 2025 Aqua Water Beach Sea Side Sports Barefoot Shoes for Boys Girls

>> China New Best Selling High Speed Paper Cups Molding Machine

>> 1L 2L 3L Plastic Bottle Making Machine 4L 5L Extrusion Blow Molding Machine

>> API DN150 ANSI 150 RF Body and Flanges in ASTM A216 Wcb Swing Check Valve for Medium Petroleum

>> Vh-300 Mixer Equipment Industrial V Shape Blender Flour Mixing Machine Vertical Dry Powder Mixing High-Speed Mixer

>> Custom Lipstick Lip Gloss Lip Gloss Lip Gloss Mailer Shipping Boxes for Lip Gloss

>> Hansshow Auto electric tailgate strut lift aftermarket power liftgate for honda odyssey 2013 2014 2015 2016 2017-2020 2021

>> wholesale gym workout custom logo printed ladies crop top pullover cotton ladies plain hooded sweatshirts hoodies for women

>> 2000W Handheld Laser Welder for Metal Iro Stainless Steel Aluminum Brass

>> SIJIN supply SGP JIS B2311 Elbow

>> Metal Wire Cup High Speed Ocean Boat Fishing Temptation Troll 20 DAIWA FUEGO SV CS Fishing Reel

>> Adjustable Vertical Lifting Column System Electric Lifting Column for Cobot Palletizer

>> No. 1fully Computerized Socks Knitting Machine

>> Warehouse Free Standing Modular Prefab Mezzanine Floor Structures Manufacturer