Ophthalmic Solution Preparation Vessel Tank System

| US$12,000.00-15,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

PYG

Application Area

Chemical

Certification

CE, ISO

Condition

New

Heating Method

Electric Heating

Insulation Material

Mineral Wool

Mixing Drum Shape

Drum

Stirring Type

Cutsomised

Warranty

1 year

Working

High Speed Mixer

Tank Work Volume:L

50 200 1000 2000 5000

Motor Power for High Shear Emulsifying:K

1.1 1.5 4.0 5.5 15

Agitator Speed for High Shear Emulsifyin

0-1400 or 0-2900

Motor Power Propeller Type Agitator G:Kw

0.37 0.75 2.5 3.0 5.5

Agitator Speed for Propeller Type Agitat

0-150

Motor Power Anchor Type Agitator G:Kw

0.55 1.5 4.0 5.5 11

Agitator Speed for Anchor Type Agitator

0-45

Inside Shell Pressure MPa

-0.1/0.3 (Can Be Done as Client′s Urs)

Jacket Pressure MPa

0.3 (Can Be Done as Client′s Urs)

If Heating by Electrical Element in The

4 8 16 30 50

Jacket Heating Medium for Electrical Ele

Steam/Hot Water

Jacket Type

Single Full/Limpet Coil/Dimple Jacket /Inside Coil

Mixer Type

Homogenizer

Layout Type

Verticle

Operating Type

Cycle Operating

Transport Package

Wooden in Package

Specification

20L-10000L

Trademark

JOSTON

Origin

Wenzhou

HS Code

8479820090

Production Capacity

30 Sets/Month

Product Description

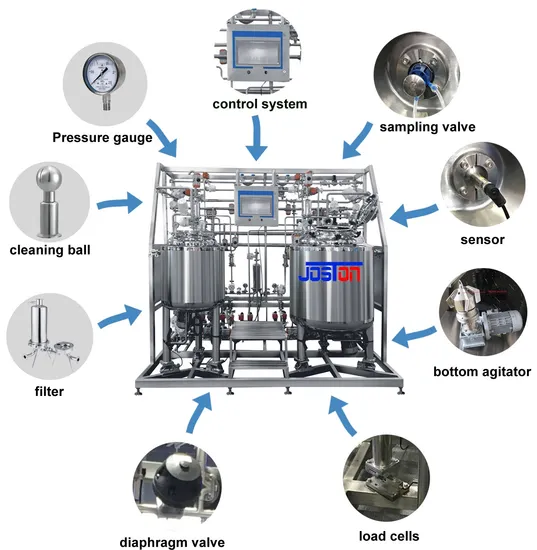

Detailed PhotosRemark:The drawing just for your reference. Product Description High Quality Stainless Steel SS304 Honey Milk Water Oil Chemical Liquid Blending Movable Steam Heating Mixing Tank is mainly used for the preparation ,emulsifying and homogenizer the suspension product ,oil phase and water phase material dissolv solution which is widely used in the sterile drugs,biological products,oral liquid ,eye drop ,syrup solution in pharmaceutical fields.

High Quality Stainless Steel SS304 Honey Milk Water Oil Chemical Liquid Blending Movable Steam Heating Mixing Tank mainly inclduing the following units:

1) manufacturing tank ( mixing tank ) : which can be single layer ,steam jacket or electrical heating jacket with insulation layer

2) bottom mounted magnetic agitator and top mounted high shear emulsifying agitator

3)control panel system : PLC/HMI control panel or common button control panel .

the advantage of PLC/HMI control system for solution preparation system:

1. Adopt aseptic design, no dead area, minimize residue.

2. PLC control of touch products, one key operation, direct and clear process flow chart, automatic liquid distribution and material transmission in the whole process; simple, convenient and user-friendly.

3. Equipped with automatic CIP online cleaning system and sip online sterilization system, the system can automatically online SIP and CIP, reducing production cost and old strength.

4. Automatic online abbreviation for filter integrity.

5. Automatic online real-time detection of weight and constant volume.

6. Automatic real-time abbreviation, recording and printing of all relevant data.

Product Parameters Technical description

| Components Item | Function and usage |

| CIP spray ball | Wash &clean tank inside surface and devices automatic ,which should connect to the CIP machine station |

| Vent filter | Filter air to prevent the bacteria into the tank ,also can release the tank inside pressure. |

| Temperature sensor (gauge)-optional | Indicate inside tank temperature and PID temperature control with the necessary valve and fittings |

| Pressure sensor (gauge) optional | Indicate the inside tank pressure |

| PH sensor optional | Indicate the product PH data |

| PO2 sensor optional | Indicate the product Oxygen content |

| Level sensor (gauge) optional | Indicate the inside tank product level height ,there are have different models :(static) pressure type ,ultrasonic type ,radar type ,glass tube type ,plate sight glass type . |

| Load cell optional | Indicate the product weight |

| VFD ( inverter ) optional | Control and adjust agitator speed |

| Safety valve optional | Release inside tank pressure to protect the tank safety |

| Flow meter optional | Indicate the solution inlet and outlet volume |

| Sight light | Indicate inside tank bright for watching easily |

| Manhole (handhole ) | Charge solid product into tank ,also can be used for maintenance inside tank components. |

| Sampling valve optional | Take inside tank products sample for offline checking |

| Model Item | PYG-50 | PYG-200 | PYG-1000 | PYG-2000 | PYG-5000 |

| Tank work volume:L | 50 | 200 | 1000 | 2000 | 5000 |

| Motor power for high shear emulsifying:Kw | 1.1 | 1.5 | 4.0 | 5.5 | 15 |

| Agitator speed for high shear emulsifying :RPM | 0-1440 or 0-2900 | ||||

| Motor power propeller type agitator g:Kw | 0.37 | 0.75 | 2.5 | 3.0 | 5.5 |

| Agitator speed for propeller type agitator :RPM | 0-150 | ||||

| Motor power anchor type agitator g:Kw | 0.55 | 1.5 | 4.0 | 5.5 | 11 |

| Agitator speed for anchor type agitator :RPM | 0-45 | ||||

| Bottom magnetic type agitator :KW | 0.18 | 1.5 | 2.2 | 3.0 | 5.5 |

| Bottom magnetic type agitator Speed RPM | 0-350 ( for the gear motor connection type ),0-600 (for direct motor connection type ) | ||||

| Inside shell pressure MPa | -0.1/0.3 (can be done as client's URS) | ||||

| Jacket pressure MPa | 0.3 (can be done as client's URS) | ||||

| Jacket heating medium | Steam/hot water | ||||

| Jacket type | Single full/limpet coil/dimple jacket /inside coil tube | ||||

Remark : we can choose the tank fittings according to the production process as the client's requirement . Company Profile

FAQ

1.What about your factory?

Our factory is located in Wenzhou city ,Zhejiang Province and have more than 15 years experience on machinery making.

2.How will your company control the equipment quality ?

We have a qualified expert team ,we will inspect every production proceed .also Machines will be tested in our plant before shipment .

3.How long the warranty will be?

We provide 1 years warranty for the machine running ,but we will afford whole -life service for the machine .

4.Which kind payment do your company do now ?

We accept Western Union, T/T ,D/P,D/C and irrevocable L/C payable etc.

5.Can we become your distributor in our country?

Yes, we very welcome you! More details will be discussed if you are interested in being our agent.

6.Why we choose "JOSTON "?

1. We enhance the reliability of product's quality and working life .

2. We decrease the consumption cost of the product in the ruuning.

3. We improve research personnel's ability to deliver a creative design;

4. We use leading technologies in our product development and innovation, and thereby increase the competitive advantage of products.

7.Do you supply installation equipment in oversea?

Yes, if need, we can send our engineer to your plant to help you do installation and commission.

8.How can we know the order production status ?

We will arrange the person to take photo or video during manufacturing in every week to make you to know the production status.When goods are finished,we will take detailed photos or video for your checking ,after approve ,then we will arrange shipment .also you can arrange FAT in our plant when the goods is ready here

9.what is kind service do you offer before making order ?

1.according to your company URS ,we will make the design drawing accoridingly.

2.after your company approved drawing ,we will make quotation.

3. final we make agreement on payment terms ,delivery time ,package ,shipment etc.

10.how about your company after-sale serivce ?

1. We provide long-term after-sale service.

2. we can do installation and commission for the equipment in your plant if necessary .

3. Meanwhile, you can call or e-mail us to consult on any relevant question since we have a special line for after-sale service. Alternatively, you can communicate on-line with us to solve any problem.

SERVICE

We have established some overseas agent office to make the after-sales serivce already ,so it can will be service client in fast response .also in our headquarter service team ,there is a expert team which can support client in 7*24 hours .

1. Customer inquiry and consultation (URS documents)

2. Confirmation of treatment plan (DQ documents &PID Drawing)

3.Quotation offer with the technolgy document (Quotation PI )

4.Engineering and Manufacturing (Prodcution &Quality inspection )

5. Product inspection (FAT documents)

6. Delivery arrangement and loading work (full set Shipment documents)

7. After-sales service (OQ,PQ ,SAT documents)

>> Plywood Hot Press/Laminating Hot Press Machine/Hydraulic Melamine Press Machine

>> Steel Wire Bobbin Winding Machine

>> Carbon peel skin whitening face laser portable q switched nd yag tattoo removal laser device

>> Quality 52cc Powerful Petrol Wood Cutting Tool Gasoline Chainsaw (HS-5200Y)

>> API 5dp Nc38 EU 3 1/2 Drill Pipe for Oilfield

>> High Quality Lab Acm Grinder with Ce&Atex Certification

>> Die-Cast Mixers Drywall Mud Mixer. Size 8-1/2" X 4-1/2", Length 30", Material Stainless. 212 * 600 * 8.8mm, Q235 Carbon Structural Steel

>> Non Woven Disposable Light Weight CPE Shoe Cover

>> Precision Metal Lathe

>> China factory supply eps foam recycling machine