Prefab Steel Structure Poultry House (BYPH-220610001)

| US$25.00-100.00 | 1 Square Meter (MOQ) |

Basic Info.

Model NO.

BYPH-220610001

Usage

Reproduction Apparatus, Layer/Broiler Feeding Equipment and House

Application

Chicken

Power Source

Electric

Heating and Ventilation Equipment Type

Air Duct

Epidemic Prevention Equipment

Mobile Vaccination Car

Blade Type

Non

Computerized

Computerized

Certification

ISO9001:2008, CE

Condition

New

Warranty

1 Year

Chicken

Layer Hen or Broiler

Feeding Equipment

Flat or Cage

Surface Treatment

Paint or Galvanized

Insulation

Glass Wool or Foam Foil Insulation

Transport Package

Ship

Specification

sqm

Trademark

XGZ

Origin

China

HS Code

8436290000

Production Capacity

30 Set/Month

Packaging & Delivery

Package Size

1200.00cm * 230.00cm * 260.00cm

Package Gross Weight

22000.000kg

Product Description

Prefab Steel Structure Poultry House(BYPH-220610001)Production Description

| a. Layer Egg Chicken Cage--HLD-4192 | |||||

| Farming Qty(birds) | Qty/Unit (birds) | Layout Plan | House Dimension(m) | ||

| line | Unit/Line | Total Unit | |||

| 10,000 | 192 | 2 | 27 | 54 | 59*8*4 |

| 20,000 | 192 | 3 | 35 | 105 | 74*12*4 |

| 30,000 | 192 | 3 | 53 | 159 | 107*12*4 |

| 40,000 | 192 | 4 | 53 | 212 | 107*14*4 |

| 50,000 | 192 | 5 | 53 | 265 | 107*17*4 |

| b. Pullet Chick Cage-- HLY-4160 | |||||

| Farming Qty(birds) | Qty/Unit (birds) | Layout Plan | House Dimension(m) | ||

| line | Unit/Line | Total Unit | |||

| 10,000 | 160 | 2 | 32 | 64 | 46*8*3.8 |

| 20,000 | 160 | 2 | 63 | 126 | 83*8*3.8 |

| 30,000 | 160 | 3 | 63 | 189 | 83*12*3.8 |

| 40,000 | 160 | 3 | 84 | 252 | 108*12*3.8 |

| 50,000 | 160 | 4 | 79 | 316 | 102*14*3.8 |

| c. Broiler Chicken Cage--HLR-3084 | |||||

| Farming Qty(birds) | Qty/Unit (birds) | Layout Plan | House Dimension(m) | ||

| line | Unit/Line | Total Unit | |||

| 10,000 | 84 | 4 | 30 | 120 | 50*10*3 |

| 20,000 | 84 | 5 | 48 | 240 | 75*12*3 |

| 30,000 | 84 | 6 | 60 | 360 | 92*14.5*3 |

| 40,000 | 84 | 7 | 69 | 483 | 105*16*3 |

| 50,000 | 84 | 8 | 75 | 600 | 113*18.5*3 |

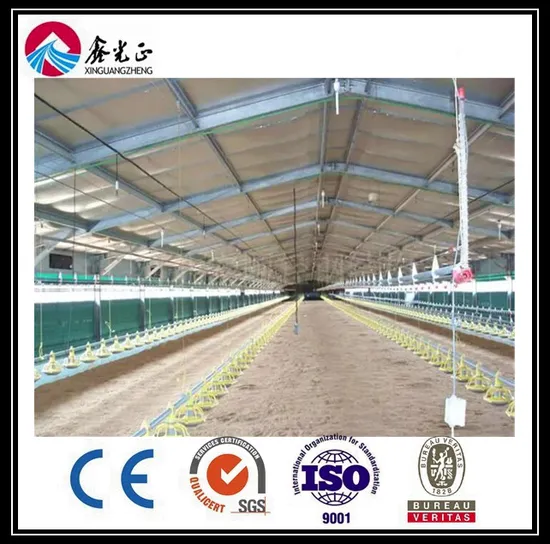

Introduction of Product:

1.The full set of equipment using hot-dip galvanized material, corrosion-resistant, which ensures the service life of 15-20 years.

2.Intensive management and automated control. Achieve automatic feeding,drinking,manure cleaning,egg collecting and environment control,can help to improve working efficiency and save labor cost.

3.High-density raising,saves land and investment.

4.Suitable for closed chicken house. Automatic control of ventilation and temperature can meet the requirement of the birds.

In addition to the chicken cages above, we also have these husbandry equipment:

We have profestional engineer team for steel structure chicken farming house

Why Choose Xinguangzheng? 1.Credit Guarantee Professional Poultry Equipment Manufacturer with over 20-year History Products has been Exported to over 80 Countries in the World 2.Quality Guarantee Full Set Automatic Equipment with High Flatness & Elegant Appearance 275g/m2 Galvanized Material with High Anti-Corrosion Effect Advanced Cage System, 20-year service life Feed Thickness Uniformity Egg Pocket with Good Elasticity, Low Rate of Broken Eggs Spare Parts Storage Service Environment Friendly 3. Cost Efficient High Quality Materials with Reasonable Price Automatic Equipment, Low Labor Cost Easily Transportation 4. Steel Structure Poultry House Combined Availablility Steel Structure Poultry House Used 275g/m2 Galvanized Material Including: 1.Foundation: Anchor Bolts, Steel Frame + Steel Sheet, Canopy 2.Beam: H-Section steel 3.Column: H/C-Section Steel 4.Roof & Wall Purlin: C-Section Steel 5.Roof & Wall Cladding: EPS Sandwich Panel or Corrugated Steel Sheet 6.Roof Bracing & Column Bracing: Round Bar 7.Tie Rod: Circular Steel Tube 8.Knee Brace: Angle Steel 9.Roof Gutter: Color Sheet Sheet 10.Rainspout: PVC Pipe 11.Door: Sliding Sandwich Panel Door or Metal Door 12.Windows: PVC/Plastic Steel/Aluminum Alloy Window 13.Connecting: High Strength Bolts 14. Package and Transportation: Loaded by 20FT GP, 40FT GP, 40FT HQ. All equipments can be customized as your demand, make the whole house more efficient. 5. Service Guarantee Professional Technician & Engineer Service Team, Various Designs Available Customized Design Acceptable One-Stop Service FAQ

Q1: What are your main products?

A: Our main products are divided into 2 parts, Steel Structure Building and Poultry Equipment.

Steel Structure Building: Workshop, Warehouse, Factory, Exhibition Hall, Profabricated Poultry House, Steel Structure Frame and Container House, etc.

Poultry Equipment for Chicken(Layer, Broiler, Breeder, Pullet), Duck, Pig, Goat, Rabbit, Quail, Pigeon, Cattle, etc.

All products can be customized as your demand.

Q2: What information should I provide before quotation?

A:

1 Location (Where the poultry house will be built?) _____country, area

Or Local Climate: Extreme Temperature _____Lowest_____Highest

2 House Size(for equipment arrangement): Length*Width*Height _____mm*_____mm*_____mm

Or Breeding Quantity: _____Chicken & Breeding density _____unit/m2

3 Voltage_____V, Power: single-phase or three-phase, _____Herz

4 Cage Type: A-Type(<30,000 recommended) or H-Type(>30,000 recommended)

5 Tier Request: _____(4-5 Tiers recommended)

Q3: What kind drawing of house will you provide?

A: Plan Drawing, Elevation Drawing, Sectional Drawing, Foundation Drawing and Installation Drawing.

If you are interested in us, please kindly find the dimensions needed for poultry equipment(Q2) for your reference. Our team will provide the best layout as your demand.

Product Description

Poultry House from Qingdao Xinguangzheng Steel Structure Co., Ltd, is easy to manage and the market is on your doorstep. A well managed chicken house is very profitable.

Primary Framing Elements-columns, beams and all primary members are made by Galvanized H section steels- hot rolled section steel/ welded section steel, which will be bolted together at site. A factory galvanization surface treatment is applied to get better anti-rusting and anticorrosion effect of primary framing elements.

Secondary Framing- Galvanized Purlin, Tie Bar, Roof and Wall Support are formed as secondary framing

Bracing

Round steel is supplied with knee bracing and other supporting parts that need portal framing, which will improve the stability and durability of the whole structural building.

Cladding

Roof and Wall are covering of steel sandwich panel, hot dipped with zinc and aluminum compound, that is fixed to the outside of structural building to protect it against bad weather or to have a good quality of insulation...

Oversea projects we undertook in the last few years:

Industrial Warehouse (13000 M2 )- Argentina

Warehouse (14000M2)---- Republic of Uzbekistan

Workshop (12000M2)----Canada

Warehouse(3600M2)---Romonia

Vegetable Market(2500M2)---- Mauritius

Pig shed(3500M2)---USA

Chicken shed(2800M2)- Austrilia

Aircraft Hangar(1300M2)------Austrilia

Warehouse(900M2)---- Mongolia

Prefabricated house(70M2)----800 sets---Angola

Container house(20')-----60 sets- South Africa

We can provide the quotation, if you confirm the information as bellow:

1. Data for design

*Wind speed(KM/H)

*Snow load (KG/M2)

*Rain load (KG/M2)

*Earthquake load if have

*Demands for doors and windows

*Crane (if have), Crane span, crane lift height, max lift capacity, max wheel pressure and min wheel pressure!

2. Material quality

*Windows and doors quantity, size and location

*Roof and wall material, sandwich panel or corrugated steel sheet (steel sheet can not heat insulation)

3. Type

*size--width, length, eave height and roof slope

*single slope or double slope

* single floor, double floor or multi floor

Steel structure poultry house

| Item | Materials | Remark |

| Steel Frame | 1 H section column and beam | Q345 steel two coats of mid-grey paint(or customized color) |

| 2 wind resistant column | Q345 steel two coats of mid-grey paint(or customized color) | |

| 3 roof horizontal bracing | φ20,Q235B steel bar, two coats of mid-grey paint(or customized color) | |

| 4 column vertical bracing | φ20,Q235B steel bar, two coats of mid-grey paint(or customized color) | |

| 5 Roof purline | Q235B C/Z section galvanized steel | |

| 6 Wall purline | Q235B C/Z section galvanized steel | |

| 7 Anchor bolts | M24 Q235B | |

| Fastener System | 1 hight strength bolts | M20*75 10.9s |

| 2 ordinary bolts | M12*55 4.8s | |

| 3 Self tapping screw | M6.3*100 | |

| 4 nuts | M20/M24 | |

| Wall and roof Protecting System | 1 Roof and wall panel | Corrugated color steel sheet |

| 2 Heat preservation materials | Fiberglass/XPE | |

| 3 Corner trim | Color steel sheet |

Feeding Equipments For layer

| Item | Remark |

| Cage frame | Material of cage and frame is hot dip galvanized steel. Zinc thickness: 260g/m2. |

| Automatic Feeding system | 1 Feeding trolley,and head and end frame |

| 2 Feed conveying and dispensing device | |

| 3 Silo Material is Hot-dip galvanized steel | |

| 4 Auger type feed uploading device for silo | |

| Automatic manure cleaning system | 1 Belt type manure cleaning machine |

| 2 Bracket for manure cleaning belt | |

| 3 Transverse manure conveying machine | |

| Egg collecting system | 1 Egg colleting machine |

| 2 Egg conveying belt | |

| Ventilation and temperature control system | 1 50'' ventilation fan |

| 2 Cooling pad | |

| 3 insulation door | |

| 4 Air inlet window | |

| Electric control system | 1 Feeding control system |

| 2 Manure cleaning control system | |

| 3 Egg collection control system | |

| 4 Temperature control system |

Feeding Equipments For Broiler

| Item | Remark |

| 1.Main Feed Line System | 1 silo |

| 2 hopper base part | |

| 3 drive system | |

| 2.Feed Pan system | 1 hopper |

| 2 drive system | |

| 3 delivery system | |

| 3.Nipple Drinking System | 1 pressure regulator |

| 2 main water inlet system | |

| 3 nipple drinking system | |

| 4.Ventilation | 1 50''cone |

| 2 36''cone | |

| 3 ventlight |

Warmly welcome your inquiry!

>> Washing Factory OEM Scent Sheet Softener Laundry Detergent Liquid

>> 480W Beam Spot Wash Cmy CTO Mega Pointe Moving Head Light

>> Black Copier Printer Laser Tn119 Konica Minolta Toner (bizhub 164/184)

>> Modern Office Furniture Cheap Cupboard Wood Filing Cabinet

>> China Factory Supply River Stone Cone Crusher for Sale Cone Crusher Quartz Grit Cone Shaped Rotary Crusher

>> Mini Bench Drilling and Milling Machine Zay7020 Zay7032 Zay7040 Zay7045

>> High Quality 730mm*730mm 730mm*1000mm PP PVC Cross-Flow Cooling Tower Filler Material

>> Eco-Friendly Acrylic Emulsion for Spray Bonded Cotton Products

>> Tractor 3-Point Light Duty 18" Disc Harrow for Hot Sale

>> Wholesale Lace Nylon Fabric Hollow Lace Wedding Dress Lace Fabric

>> MID Driver Ebike Electric Bike Hot Sale Wholesale Custom 27.5inch 48V 500W Lithium Battery OEM Aluminum Alloy 11 Speed 20 Ah

>> High-Performance Nij Iiia Aramid 9mm Resist Ballistic Visor Face Bulletproof Mask

>> Small Recycling Shredder Plastic Machine for Hard Disk Shredder/Crusher Machine

>> Yonthin Tajima 9/12/15 Colors 6 Head Embroidery Making Machine Computerized Brother Price for Sale

>> Tactical Military Style Desert Men′ S Military Style Ankle Shoes

>> China Dsw Manual Pull Stations Manufacturer

>> Diamond hole flattened sheet with frame expanded metal mesh for ceiling mesh

>> Handheld Fiber Laser Welding Machine 1000W 4000W Stainless Steel

>> Body building wear deep cut sleeve less Tank top for men cotton spandex jersey custom gym stringer vest

>> Digital TWS Hearing Aids With Blue-tooth Invisible Hearing Aid Cable Manufacturer Hearing Aid Blue-tooth Rechargeable

>> Fixtec Agricultural 12L Battery Powered Pump Backpack Chemical Fertilizer Portable Electric Backpack Sprayer

>> 2021 Industrial Food Steam Jacket Kettle (CE certificate)

>> Syntec System Automatic CNC Lathe Slm266-1 Swiss Type CNC Lathe Machine

>> Disposable Non Woven Strip Cap with Single /Double Elastic Bouffant Cap 10GSM

>> Bestchickencage Ventilation Control System China Reverse Osmosis System Manufacturing ODM Custom Air Circulation Ventilation System for Poultry Houses

>> Drill Press Vise (#21183) , Germany Type

>> Tesab1012 Impact Crusher Wear Parts Blow Bar 2-423-3

>> 380g Cotton Sports Running Boys Shorts Wholesale Custom Toddler Children Baby for Kids Casual Woven Solid Trousers

>> China Factory CE Approved 500kg Mini Electric Chain Hoist with New Design

>> Mz73212c Railing Type Drilling Machine with Large Drilling Range