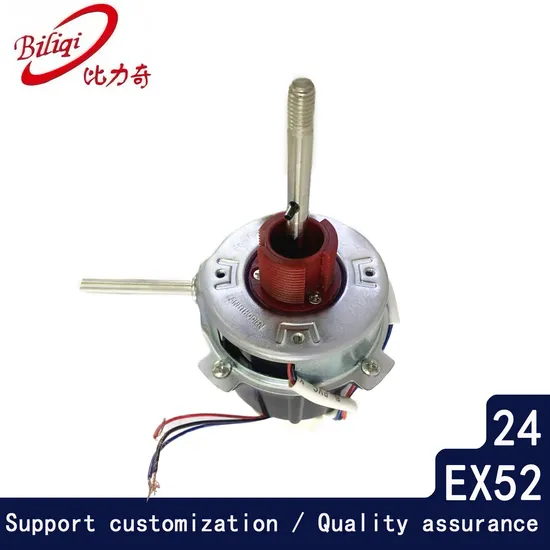

Vietnamese Brushless Motor Electrical Exhaust BLDC DC High Voltage Outdoor Standing Fan

| US$5.20-5.50 | 100 Pieces (MOQ) |

Basic Info.

Model NO.

Model: 24-EX52GNV

Excitation Mode

Shunt

Function

Driving

Casing Protection

Protection Type

Number of Poles

12

Structure and Working Principle

Brushless

Type

Z4

Certification

ISO9001

Brand

Biliqi

Working Voltage

DC: 12/24V Select as Needed

Power

Debugging on Demand

Electric Current

0.1A~2A

Stator

Silicon Steel Sheets

Rotor

Magnetic Ring

Winding

QA/Qz Pure Copper

Wire Frame

Compound /RoHS

Driving Plate

External or Internal

Shell

Aluminum or Electroplated or Electrophoresis

Shaft

45# Carbon Steel, Customized Size

Bearing

Ball Bearing

Synchronous Motor

AC and DC, Hv and LV

Polar Logarithm

8~12

Transport Package

Carton

Trademark

BiLiQi

Origin

Shunde, Foshan City, Guangdong Province, China

HS Code

8501310000

Production Capacity

1.5 Million PCS/Year

Product Description

Brushless motorBrushless motor adopts automatic production process, and the processing of all parts is controlled by computer, accepted by computer, with meticulous quality.

Compared with AC motor, BLDCM has the advantages of energy saving, environmental protection, durability, high speed, low power consumption and large torque.

For the same motor, the efficiency of the motor can be changed according to different requirements within the range value and according to the driver program. It can achieve rated speed and rated power. Under different load conditions,rated speed can reach constant speed through self-regulation of power. Rated power under different load,

lock the power and change the load speed. Realize the concept of "the same motor, different products".

Brushless motor deeply loved and adopted by the home appliance industry at home and abroad, can be debugged and customized according

to the requirements.

Product test data

| 12V | Fast | Middle | Slow | Remarks | |||

| Electric current ( mA ) | 483 | 432 | 389 | The BLDCM can be used for multiple gears, and only three gears are designed for the display motor Test equipment includes: AC frequency converter, AC to DC power supply, control board | |||

| Power ( W ) | 45 | 38 | 25 | ||||

| Rotational speed ( RPM) | 1200 | 1050 | 868 | ||||

| Air volume (m/s) | 8.0 | 6.6 | 5.4 | ||||

| Temperature rise (K ) |

BLQ motor to achieve automatic production, the use of machine winding, wire drop, wire binding, soldering, acceptance, all controlled by computer, from production to acceptance, strict quality control, meticulous, obvious to all

All kinds of High Speed and High Precision stamping equipment in stamping Workshop,Professional equipment operators ensure the normal operation of the equipment and ensure the quality and stability of the products

Q1: Are you factory?

A: Yes, we have been in designing and providing excellent motors for customers. Our factory production is all under ISO9001 quality management system.

Q2: How long you could prepare samples?

A: Normally 3 days if we have the sample in hand. If customized one, about a week around

Q3: How about batch order production?

A: Normally 15-30 days, the customized or newly developed products may take more half month.

Q4: Do you inspect the finished products?

A: Yes, we do inspection according to ISO9001 standard and ruled by our experienced QC staff.

Q5: What advantage do you have?

A: For the motors, we have long enough of 18months guarantee, and for the service, we offer 24 hours technical support and barrier-free communication.

>> 4mm Environmental Decoration Panel-Aluminum Composite Panel/ACP

>> 2024 High Quality Three-Spindles Vertical Machining Center Pj-966 Milling Machine Vmc Machine Faucet Machining Centre

>> Magnesium Sulfate Pellet Mill with CE

>> Taijia TDS 100m modular ultrasonic portable flowmeter ultrasonic flow meter dalian pipeline ultrasonic flowmeter

>> Sell Kenya 4-8 Layer Galvanized Stainless Steel Poultry Farm Egg Layer Chicken Coop

>> Specifice Victoria Perfume Female Body Spray

>> Economical and Practical Three-Point Suspension Combine Potato Onion Harvester

>> New Car/Auto Alternator Fit Hyundai Atos 1.0L (12V 60A CW) 23039

>> Bedroom casement sliding window aluminium windows mosquito net roll

>> Brazing Tips of Circle Saw Blades Brazing Machines with Auto System

>> Hot Sale! Sch40s Good Quality Butt Weld Stainless Steel Pipe Fittings

>> Big Swing Diameter Heavy Duty Lathe Machine at Best Price Cw61160

>> Manual Wafer Type Butterfly Valve

>> Yamamoto Motorcycle Parts Rear Spring-Air Shock Absorber with Gas Tank for YAMAHA 100 (K120) Sport Blue Spring

>> Grommet Blackout Green Curtains for Bedroom and Living Room, Thermal Insulated Room Darkening Curtains

>> Ultimate Leg Massager Kit for Deep Tissue Relief and Relaxation Leg Manipulator Deep Massage Small Piece Massage

>> Aluminum Profile High-Speed Four-Axis CNC Machining Center Efficient and Intelligent Door and Window Drilling Machine

>> Revolutionize Waste Processing with Single-Axis Shredder Crusher with 2 Shafts

>> Rack and Pinion Building Hoist Construction Elevator Sc100 Lift

>> Breathable Outdoor Work Safety Shoes Low Cut S3 Steel Toe Safety Shoes

>> Pet Bottles Crushing Washing Drying Machine Unpacking Machine De-Baler for Pet Bottles Washing Line

>> Windows casement with glass windows aluminum profile 2021 electronic house window

>> 5 Axis Axes CNC Bridge Saw Machine CNC Stone Cutting Machine, for Marble Granite Quartz Quartzite, for Processing Slab Countertop Tombstone

>> House Designs Clay Bricks Exterior Wall Facade Clinker Tiles 60X240mm Exterior Wall Tile Facades Red Clay Brick

>> Sh1659 2020 Bling Lady Diamond Purse Handbag Designer Chain Shoulder Bag Quilted Stone Pattern PU Leather Crossbody Bags for Women

>> Empty Container Antiperspirant Fragrant Solid Stick Balm Body Refill Deodorant Stick Bottle

>> Wrist Brace for Carpal Tunnel Professional Compression Wrist Splint for Pain Relief Arthritis

>> Emerson Delta V PLC MODULE KJ2201X1-BA1 12P3162X202 12P3162X252 12P3162X182 12P3162X242 12P3162X212 KL2101X1-BA1 12P4987X162 SLS 1508 SIS Logic Solver module

>> Rechargeable invisible ear sound amplifier hearing aid

>> Maximum 100 Ton High Capacity 200mm Stroke Bottle Shape Mechanical Lifting Jack