Equipment and Technology of The Solid State Polycondensation for Pet Chip

| US$15,000.00-235,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

RS-SSP

Material Processed

Plastic Flakes

Plastic Type

PET

Screw

Batch Type

Automation

Automation

Computerized

Computerized

Certification

QS, ISO9001:2008, CE

Heating Method

Electricity to Heating Oil

Material Status

Powder, Pellets, Pieces, Scraps, Chips

Vacuum Method

Roots Pump

Volume

From 5L to 46000L

Function

Improve Material Viscosity

Vacuum Degree

Less Than 1PA

Maximum Temperature

250°c

Working Time

26-32 Hours(According to Target IV)

Cooling Method

Air Fan

Nitrogen

Necessary for Pet Scraps

Transport Package

Wooden Pallet and Film Cover

Specification

20m* 20m* 7m

Trademark

RONGSHENG

Origin

Jiangsu, China

HS Code

8419899090

Production Capacity

80 Set / Year

Product Description

Product DescriptionRaw material: Resin or recycled PET, PA6, PA66, PTT

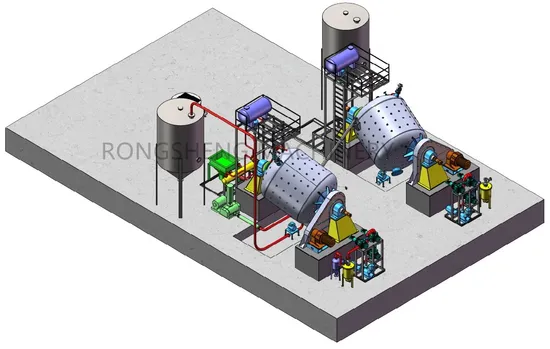

The solid state viscosity increasing device consists of: drum reactor, thermal oil heating and cooling system, vacuum system, electrical PLC (or DCS) control, etc.

And optional: automatic feeding and conveying, pre-crystallization system, automatic discharging and conveying, raw material dust removal and screening, nitrogen protection, etc.

The increase in IV(Intrinsic Viscosity) is based on the molecular characteristics of the copolymer. At the critical temperature, thanks to the special extreme vacuum technology and high-precision temperature control, small molecular weight chemicals will be extracted along with the vacuum pipeline and the copolymer molecular chain will be extended so that In order to meet the requirements of increasing viscosity, IV(Intrinsic Viscosity) can be steadily increased and high-purity and high-viscosity PET can be obtained, which can be used in spinning, industrial yarn, POY, FDY, packaging sheet, preform production and bottle-to-bottle recycling.

Product Parameters

Machine model: From 5 L to 46 cubes, Customized according to production capacity Out-put capacity: From 1Kg/ batch to 23000kg/ batch One batch time: 26 hours to 36 hours (Depends on target IV and original IV)

Detailed Photos

After Sales Service

It has a on-line system that can monitor customer process parameters and machine running at any time. When there is a problem with the customer's equipment, our company can quickly determine equipment problems and process problems through the on-line system. For some problems that cannot be solved by customers, our company will send engineers directly. Guarantee period and after-sales services:13 months since date of bill of lading During this guarantee period, Rongsheng will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, Rongsheng will provide the buyer spare parts at cost price. Long-term service: Rongsheng will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

Certifications

Installation Instructions

After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc. Rongsheng will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory. Engineer will give free training lessons to labors in buyer's factory. In some countries like India, Vietnam, we have local person who can go to customer factory for machine installation and testing.

Our Advantages

1. We are a original factory.

2. We have our own technical team

3. We can provide a complete set of solutions, SSP, LSP, washing and recycling machine, bottle to bottle, pelletizing machine.

4. We can provide upstream and downstream solutions, such as recycling equipment, granulation equipment, dryer, conveyor.

5. You can visit local equipment directly in some countries.

6. If you come to visit our company, we can take you to vist running machines in customers factory in China. To prove our company's professionalism and the good quality of our company's equipment.

Thanks, please email me.

>> CH-Jia High Speed Industrial Embroidery Machine 925

>> Two Way Radio Audio Adaptor for Motorola Gp344/Gp388/Ex500 to Motorola Visar

>> Stainless Steel or Al Electrical/Steam Heating Wood Drying Chamber Stoving Logs Drying Wood

>> Multi Needle Quilting Machine for Mattress Machine

>> L Type Lone Core Composer

>> High Purity Rare Earth Metal Block 99.5% Samarium

>> Private Label Health Eyes Gummies Supplement for Eye Care

>> Customized Double Shoulder Guitar Music Backpack Instrument Bag Case (CY3586)

>> Access Control Supermarket Products Security Scanner Door EAS Am Systems Anti Theft Alarm System for Supermarket

>> Swim Beach Pool Surf Yoga for Women Men Barefoot Quick-Dry Water Sports Shoes Aqua Socks

>> International Logistics Shipping Rates LCL/FCL Service to Door Dg Cargo Shipping

>> Cheap Electric Unicycle 45km/H 750 Wh Electric Suspended Unicycle Inmotion V9

>> Blend Nitrile Gloves Powder Free Nitrile Gloves Non Sterile Disposable Cleaning Gloves

>> Double Heat-Resistant Rubberwood Handle Square Baking Tray

>> Reflective 360 Degree Remote Controlled Tempered Glass Solar Road Studs

>> OEM Fashion Leather Strap Skeleton Wristwatches Luxury Female Automatic Hand Watches Customized Private Label Watch

>> Non-Rust Anti-Hurricane Glass Railing with Luxury Design Style

>> NdFeB Wholesale Strong Magnet Sintered N35 Rare Earth Permanent Cylinder Neodymium Magnet

>> Automatic Tea Paper Cup Production Equipment for Bulk Orders

>> Decorative curtain wall panel mesh perforated metal mesh

>> Auto Parts Car Front Bumper For Toyota Corolla 2014 SE USA

>> CF - 1L Wholesale Mixer Rubber Plastic Processing Machinery Lab Internal Mixer Rubber Keander

>> Auto Engine Parts Cylinder Head for Nissan Yd25 11039-Ec00A Toyota 2kdftv/1kzte/1kd/2kd/22r 11101-35060 11101-73020 2tr/2e 11101-19156 Wl Wl31-10-100 3rz Zd30

>> Foldable Galvanized Stackablecontainer 500kgs with Heavy Duty Construction Wire Mesh Storage Cage

>> Auto TPMS Tire Sensor Tire Pressure for Benz/GM 0009050030/0009051804/0009052102/0025407917/0045425618/0045429718/13581558/12768826/22854866/20922900/

>> General Type T. C. T Saw Blade for Cutting Wood/Hard Wood

>> Wholesale 3# Invisible Lace Zipper Long Chain for Garment Using

>> Temite Proof Draft Proof UPVC French Doors PVC Front French Door

>> High Speed Multi-Functional CNC 5 Axis Stone Machinery for Sale Support Countertop Measuring Gauge

>> Whole Production Line Bottle Pure Mineral Drinking Water Factory Plant Filling Machine