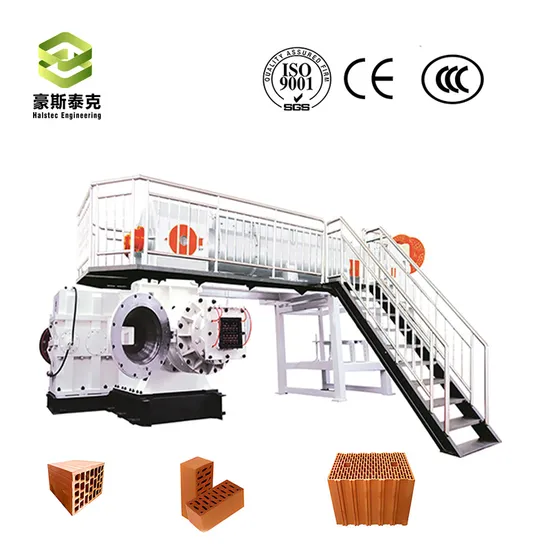

Clay Brick Making Machine Jky55 Double Stage Vacuum Extruder with 11000-25000 Bricks Hourly for Automatic Clay Bricks Production Line

| US$76,500.00-78,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

JKY55

Certification

CE, ISO

Customized

Customized

Automatic Grade

Automatic

Type

Vacuum Extruder

Capacity

11000-25000 Bricks/Hr

Power

200+110

Function

to Extruding Mud Columns

Application

Red Bricks, Clay Bricks

Transport Package

Nude in The Container

Specification

welded with high quality steel

Trademark

Halstec

Origin

China

HS Code

8474809090

Production Capacity

11000-25000 Bricks/Hr

Product Description

Clay Brick Making Machine Jky55 Double Stage Vacuum Extruder With 11000-25000 Bricks Hourly for Automatic Clay Bricks Production LineProduct Description

JKY55 Clay Brick Making Machines are the perfect choice to make solid and hollow clay bricks.

The equipment is used to fully mix the processed brick-making materials in upstream mixing tank and then extrude them into the vacuum chamber where the vacuum pump will extract most of the gas in the materials in order to enhance the plasticity, adhesion and density of materials, and finally extrude the materials under downstream high pressure, so as to produce high-strength hollow bricks or raw hollow bricks.

This full steel design hollow clay brick making machine is designed to provide a long-lasting usage life and can process a variety of materials, including clay, shale, coal gangue, slurry, etc. Its automatic clay brick making features help to save labor costs and maximize efficiency.

Product Parameters

| Name | Clay Brick Making Machines | Condition | New |

| Type | Hollow Clay Brick Making Machine | Production Capacity | 11000-25000 bricks/hr |

| Material | Clay, Shale, Coal Gangue, Slurry, Etc... | Power | 200+110 |

| Operation | Automatic | Certificate | ISO 9001 |

| Allowable Pressure | 3.5MPa,4.0MPa | Design | Full Steel Design With Longer Usage Life |

| Method | Vacuum Exturding | Transport Package | Nude in the container |

| Trademark | Halstec | Vacuum Degree | ≤-0.092 |

| Origin | China | HS Code | 8474809090 |

Spare Parts

After Sales Service

Clay Brick Making Machines Technical Support and Service

The team at Clay Brick Making Machines provide technical support and service to ensure your machine is operating correctly and efficiently. Our experienced team of technicians can provide maintenance, repair and troubleshooting services to ensure your machine is working properly and safely.

We also provide online customer service and technical support so you can get the answers you need quickly and easily. Our customer service team will be happy to help you with any questions or issues you may have.

We also offer training and installation services to ensure your machine is running correctly and safely. Our technicians can assist you in setting up the machine and provide you with the necessary information to ensure the safe and efficient operation of the machine.

Our technicians are also available to answer any questions you may have about the operation and maintenance of your machine. We are committed to providing you with the highest level of customer service and technical support.

Packaging & Shipping

Packaging and Shipping for Clay Brick Making Machines:

The Clay Brick Making Machines will be carefully packaged and shipped with extra protection to ensure safe arrival.

We offer several shipping options including air, sea, and land freight.

We can provide door to door delivery to most locations.

The delivery time depends on the destination and the shipping method chosen.

Flow Chart&Finished Brick

Flow Chart

Finished Brick

According to different usage purpose, finished bricks can be divided into out-wall decoration bricks, and inner-wall construction bricks.

Out-wall decoration bricks come with smooth surface and uniform color , and normally burning fuel is natural gas or coal powder, which is showered into the burning kiln by specific tube system. Out-wall decoration bricks also can be called as Face bricks.

Inner-wall construction bricks, normally featured with rough surface, but higher strength. Burning fuel for inner-wall construction bricks is coal, which can be added into the raw materials, or threw from the top of burning kiln.

Below is the sample for finished bricks, the size, shape and hole rate can be customized as the production requirements of clients.

Customers Show&Project Show

Customers Show

With around 20 years experience of international trading, Halstec has set up more than 200 brick factories all over the world, such as Indonesia, Uzbekistan, India, Myanmar, Vietnam, South Africa, Zimbabwe, Bangladesh, etc. Below is the glimpse of our clients, hope can be your partner in very soon future.

Project Show

Uzbekistan

Project: Uzbekistan Rotary Kiln

Kiln Location: Tashkent

Kiln Section: 12.98m

Kiln Capacity: 800,000 bricks /day

Materials: mountain earth, coal gangue

Quang Binh, Vietnam

Project: Quang Binh, Brick Factory

Location: Quang Binh, Vietnam

Kiln Capacity: 400,000-500,000 bricks /day

Materials: shale, river sludge, construction waste, industrial tailings

Certifications

FAQ

Q1: What can the machines be used for ?

These brick making machines can be used to produce fired red clay bricks, solid bricks, hollow bricks, perforated bricks, fired clay bricks, etc.

If you want to set up one brick factory, make bricks and sell bricks, then you will need these machines.

Q2: How much the machines or whole production line?

Price could be huge difference according to different production requirements. For example, one day make 100000 bricks, one day 200000 bricks, or one day 300000 bricks, would need different model, different capacity machines, also kilns. So if wanna to get accurate reference price, then better consider what kind of factory you want to own first.

You can get reference invest idea as: 200000USD, 500000USD, 1000000USD... etc

Q3: What will be needed for one brick factory?

Actually, when you have an idea to set up brick factory, you have to think about the land, electricity, workshop, brick machines, electrical equipment, brick dryer, brick oven/kiln, etc.

Q4: What should be consider before setup one new automatic brick plant?

-Better to make some investigation for local market requirements, find out which capacity is good to run, for example, one day 100000 bricks, one day 200000 bricks, or one day 300000 bricks?

-Then confirm the brick type and size, and related daily quantity.

- Get the initiatory design for whole line, which can be reference for land purchase.

-Confirm the raw materials condition, better make a material test before purchase land.

-Burn bricks will need burning fuel, so coal powder or natural gas, which one is available.

-Combine the investment to confirm final design for whole brick manufacturing plant.

-Start purchase and construction work...

>> Excavator Bucket Adapter Bucket Tips Tooth Point Backhoe Tiger Teeth

>> Watch Adjuster Strap Adjustment Watch Band Length Tool Stainless Steel Metal Watch Band Bracelet Length Adjusting Strap Tool

>> High Quality 50g 75g Round Deodorant Tube Container

>> Galvanized Steel Portable Horse Stables with Corrosion-Resistant Coating

>> Tension Graphic LED Textile Seg Light Box Frameless Advertising Sign Illuminated Panel

>> High Quality Lathe Machine with CE Approved (C6240H)

>> Timing Chain Kit for Nissan YD22DDTI D40 OEM 13028AD202 13028AD212 Double Chain Kit TK9070-5

>> High Efficiently Customized CNC Double Head Face Milling Machine-Floor Type Face Milling Machine

>> Medical Teaching Equipment Dental Demonstration Model

>> DRM-20s Drill Sharpener/Face Milling Cutter Grinder

>> Easy Care Straight Mens Wedding Trousers Business Formal Men Dress Pants Black

>> Custom Logo Printing PU Leather Travel Souvenir Gift Waterproof Evil Eye Makeup Bag

>> ceramic tile dimensions and surface quality tester

>> Customized Cost Effective High Power Motor Import Manufacturer CNC Turning-Milling Compound Machine

>> High Quality Automatic Chicken Feeder Houses for Sale in Kenya

>> Manufacturer Customized Engineering Plastic Bar 1M Grey Rigid PVC Rod

>> Atc CNC Wood Carving Machine A4-1530-L8-E 1325/1530 Metal CNC Router Machine with 9kw Atc Spindle for Furniture Industry

>> Automatic Rotary Two Colors Plastic Gumboots Making Machine

>> 3kilowatts Beach Cruiser Ebike/Two Kilowatt Chopperharley Headlamp Pedelec/Vintage Taillight Velos/Smyinz Big Disc Brakes Fiets/Supermoto6X17tyre Bicielettrica

>> Brass Commerical Strip C2200 F18 F11 Ordnance Factories Military Materials Bidding Cups Raw Material

>> 8CH H. 265 CCTV Security Surveillance 1080P Full HD Real Time Analog DVR and IP Camera Network NVR as Hybrid Xvr HVR Recorder

>> 100% Top 1 Quality Copper Mould Plate, Copper Mould for Continuous Castings

>> IP44 9W 12W 15W 20W 30W COB Recessed LED Downlight, Ceiling Recessed COB LED Down Light

>> 2024 Popular Selling Power Tools Cordless Keyless Drill

>> Advanced Design Portable Lifting Truck Crane 360 Degree Rotational Angle

>> Food Grade Vacuum Homogenizing Equipment Cosmetic Viscous Product Manufacturing Processing Line Disperser Blender Mixer Pharmaceutical Lipstick Mixing Machine

>> CT3325 28mm Spindle Bore Metal Machining China Combo 3 in 1 Lathe Machine

>> Affordable China - Worldwide Air Shipping Air Freight Fast Air Service Air Shipping Experts Huangyang

>> 30~50HP Matched Power Efgc Mower Tractor Pull Implements Cutting Glasses Riding Mower

>> Carpet Overedge Serging Sewing Machine Carpet Overedging Machine for Carper Factory