2024new Tech Waste Turbine Oil Purify Machine Near-New Qil Condition

| US$40,000.00-50,000.00 | 1 Ton (MOQ) |

Basic Info.

Model NO.

DTS6

Type

Distillation Equipment

Object

Waste Oil

Separation Mode

Sedimentation Type

Operating Type

Continuous Type

Installation

Finished Product

Distillation Equipment Type

Steam Distillation Equipment

Pressure

Low Pressure

Condition

New

Raw Materal

Used Lube Oil

Product

Regenerat Lube Oil

Certification

CE/Ios

Heating Temp

80 Degree Centigrade

Transport Package

Container

Specification

300L/450L/600L/800L/1T

Trademark

Fangsheng

Origin

Chongqing, China

HS Code

8419409090

Production Capacity

80 Sets Per Year

Product Description

Product Description It is an upgraded version of the DTS Multifunctional Decolorization and Purification All-in-One Machine. It can achieve waste oil purification at temperatures below 100 degrees, without damaging the oil film and ensuring maximum oil quality, resulting in a 100% reduction of original oil indicators.

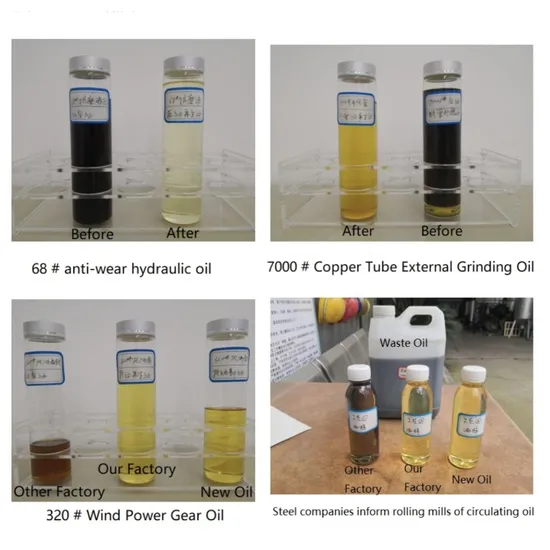

Detailed Photos

Our Advantages

| Competing Industry Equipment | Our Company's Equipment | Comparative Advantages |

| Filter elements or paper filters | No filter elements | Reduces consumable costs, eliminates the need for filter cleaning, easy to operate, saves time |

| High electricity consumption | Energy-efficient | Uses electromagnetic induction, saving 50% on electricity |

| Direct heating | Constant temperature indirect heating | Constant temperature heating protects the oil quality, preventing rapid aging of the oil |

| High-temperature direct heating | 360-degree indirect surround heating | Significantly improves safety |

| Physical filtration | Flocculation purification | Can purify nanoscale impurities |

| Direct evaporation to remove moisture | Flocculation adsorption of moisture | Saves energy, maintains the essence of the oil, does not produce sludge |

| Cannot process heavily soiled oil | No restrictions | Broad processing range, strong processing capability |

| Processed oil color is similar to waste oil | Processed oil color is 99.9% similar to new oil | Processed oil does not change color |

| Can only accept moisture and mechanical impurities | Meets national standards (GB)Can accept all indicators | Allows customers to send samples for laboratory testing of all indicators |

| Processed oil can only be used in simple cooling systems | Reusable in the original system and equipment | Can be used repeatedly in cycles |

| Degradation of oil quality | No degradation of oil quality | Reduces the cost of purchasing oil |

Company Profile

Our Team

Certifications

Our Factory

FAQ Q: Is the anti-wear coefficient in lubricating oil affected after the equipment is used for decolorization and filtration?

A: The DTS6 operates at medium to low temperatures and can fully restore the color appearance and kinematic viscosity of the oil without harming its anti-wear coefficient.

Q: Is a filter element required for DTS-6?

A: The DTS-6 utilizes its own proprietary flocculation technology.Flocculants can remove up to 99% of impurities from oil.There is no need for a filter element

Q: What is the oil output of DTS-6?

A: The oil output ranges from 90% to 99%. The exact amount of oil output depends on the raw material.

Q: Does the equipment heat directly?

A: No, we use the latest technology of electromagnetic eddy current indirect heating, which is more energy-efficient and safer.

>> Adults Custom Sock Happy Design High Elastic Colorful Dress Breathable Sport Sock Cotton Fashion Women Men Socks Cotton Custom Logo Longer Length Socks

>> Daly 12L LPG Cylinder for Cooking

>> OEM Low Price Mixer Machine for Cosmetic Making Cosmetic Cream Emulsifying Machine

>> Creality Cr-Scan Raptor 3D Scanner Handheld High Precision Scanners

>> High Strength Waste Paper Recycling Test Liner Paper Making Machine

>> Hot Sale Middle/Side Gear Farm Tractor Rotary Tiller for Dry Land with Low Cost

>> Inflatable Unicorn Bounce House Moonwalk With Slide For Party Events

>> Fast Delivery Disposable Level 2 3 Ply Non Woven Medical Face Mask

>> Profibus Cable PA 1X2X18AWG Industrial Communication Control Cable Fieldbus Cable Belden 1 Pair Signal Bulk Copper Wiring Twisted Pair /Prysmian PE/Fpe/PVC

>> 8040 FRP membrane shell ro 4040 pressure vessel shell FRP vessel

>> Manufacturer Garden Farm Bypass Fittings 16mm Plastic Agriculture Irrigation Threaded Water Mini Valve for Hose and Pipe Dripline

>> Wholesale Disposable Medical-Use Infusion Set with 62mm Drip Chamber

>> PP ABS PS Flakes Plastic Granulator Machine for Two Stage Water Cooling Strand Recycling Pelletizing Line

>> Insta360 Go 3 Ultra Compact Action Camera with Stabilization

>> 100% DTY Recycle Polyester Yarn Filament DTY FDY POY Yarn Type Polyester Yarn

>> Steel Structure Weldments Through Type Roller Conveyor Shot Blasting Machine

>> Fashionable Custom Purple Shorts of Elastic on the Waist

>> Wholesale Paint by Numbers Stars and Moon Handmade Oil DIY Painting

>> Various specifications of FRP water tanks Softened resin tanks frp tank 1054

>> Customized 0.5-200L PP PE HDPE Bottle Extrusion Blowing Molding Machine

>> Metal Powder Grade 100.29 Iron Powder Price

>> 800L Concrete Bucket for Manufacturer Sale

>> 70X70X15mm 12V Electric Motor Brushless DC Cooling Fan

>> 500W Cmy DJ Price Sharpy Beam Disco DMX Stage Lighting LED Moving Head Light

>> OFC 48cores Dome Enclosure for Fiber Optic Cable Joint Closure Juction Box

>> USB 3.0 a Male to Micro B Male Camera Link Cable with Screw Lock

>> HYE-3000 Electro-hydraulic Servo Compression Testing Machine

>> Dial Indicator 0-10mm (MG51313)

>> Wall Mount Relay Type AC Automatic Voltage Regulator with LCD Dislay with 4 Sockets Optional

>> 50L Pressurized Water Heater Buffer Tank with Heat Exchanger Coil