Household Appliances Furniture Boxs Custom China Mold Injection Molding Used Moulding Plastic Mould

| US$3.00 | 10 Pieces (MOQ) |

Basic Info.

Model NO.

Aut Service Plastic Molding Parts

Surface Finish Process

Polishing

Mould Cavity

Single Cavity

Plastic Material

Plastic

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Certification

ISO

Standard

HASCO

Customized

Customized

After-sales Service

Custom

Color

Custom

Thickness

1-20mm

Drawing Format

2D/(Pdf/CAD)3D(Iges/Step)

Service

OEM\ODM

Transport Package

Boxs

Specification

custom

Trademark

gz-plastic

Origin

China

Production Capacity

5000PCS/Month

Packaging & Delivery

Package Size

40.00cm * 40.00cm * 50.00cm

Package Gross Weight

10.000kg

Product Description

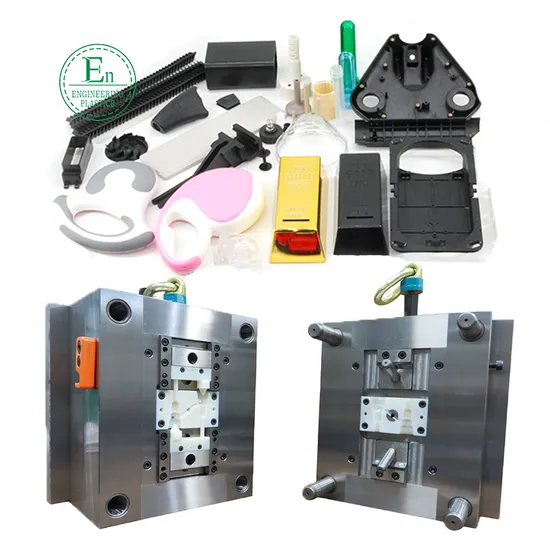

Leading Global Injection Molding Supplier Assist global clients in professional custom injection molding service,CNC machining service and engineering material.We can provide you with one-stop solutions.Main Product: 1.Custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment(paint, print, water trans-print, welding, assemble) . 2.Engineering plastics products Processing: gear and rack,guide,pulley,guide rail,Sealing ring,rod,Tube,and many machined parts ect. Products Tolerance +/-0.01mm.

How to get a quotation: 1. Prepare a picture or 3D drawings; 2. You want the products material;

| Company Name | Guangdong Engineering plastics Industries(Group)Co,Ltd |

| Brand | Guangdong Engineering plastics |

| Main Product | Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc |

| Injection Machine (Double Color) | 88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T |

| Application | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc |

| Mould Base | LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc. |

| Mould Material | 718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc |

| Moud Precision | +/-0.01mm |

| Mould Life | 100K-1000K shots |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Manufacturing Equipments | Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc. |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Lead time | 15-30 working days for injection moulds,plastic products according to quantity |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Our Spirit | "Engineering Plastics" can be used instead of "Steel"! Science and technology will change the future! Guangdong Engineering Plastics Industries Company! |

| Other | 24 hours instant and comfortable customer service! |

| Shipping status notification during delivery! | |

| Regular notification of new styles & hot selling styles! |

The production process of injection mold refers to the process of melting plastic raw materials by heating, then injecting them into the mold, cooling and solidification, and finally obtaining the required molding products. Injection mold production process mainly includes the following steps:

1. Pretreatment of plastic raw materials: including drying, mixing, adding color and other processing to ensure the quality and stability of plastic raw materials.

2. Mold design and manufacturing: according to the shape, size, material and other requirements of the required molding products, design the corresponding mold and manufacture.

3. Injection molding: the pre-treated plastic raw materials are heated and melted, and then injected into the mold, and after cooling and solidification, the required molding product is finally obtained.

4. Finished product treatment: including slag removal, trimming, grinding, painting and other treatments to improve the quality and beauty of the finished product.

Certifications

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Application

Our Factory

Our Exhibition

Cooperative Case

>> Wholesale Sport Unisex Men Women Soccer Football Non Slip Grip Crew Cotton Socks

>> Portable Bi RF IR Body Slimming Vela Vacuum Roller Machine

>> 100%Polyester Bonded Knitting Velvet Burnout Velvet (Ice)

>> America PVC Designs Shaker Style Custom Made Modern Style Luxury Home Furniture Finish Shaker Furniture Kitchen Cabinets with Kitchen Island Basic Customization

>> Guangzhou Skmei 1716 silica strap led light wristwatch waterproof 24 hour digital sports kids watch minimalist

>> SINOBI Classic Masculinity Watch with Date/Day Window Businessman Wristwatchs Dropshipping Watch

>> SINOBI Man And Woman Unisex Watch S9598G High School Student Watches Low Price Simply Style Wristwatch Jam Tangan Pria

>> Food Milk Powder Ribbon Blender Green Tea Flour Mixing Machine

>> M5 Pulley of Jacquard Modules

>> OEM Size 30 Layers Peel off Floor Anti-Slip Cleanroom Adhesive Sticky Mats

>> Yonthin Tajima 8 Head Flat Embroidery Machine for Ready Garment and Cap Industrial Brother Má Quina Cheap Prices Sale

>> Durable HDPE Rescue Can Featuring 6 Handles and Nylon Rope (EGS-002A)

>> Factory supply Fiberglass frp grp floor grating price plastic walkway grill

>> Premium Eco Friendly Customized Cork Wall Panels Good Acoustic Heat Insulation

>> Rare Earth Neodymium Magnet Manufacturer

>> High Power 1800W-3000W BLDC Motor with Nmrv Worm Reducer Electric Vehicle Motors

>> Time Delay Monitoring Relay 0.1s~100h

>> Wholesale Dog Treats Canned Pet Snack Dog Food Companion Wet Food for Cats

>> Folded Dipole Omni Directional 2400-2500 MHz 2.4G 5Dbi Router Wifi Antenna

>> Automatic Forming Paper Plate Coffee Tea Paper Cup Making Machine Price

>> European 200L Remote Control Interior Sensor Glass Sliding Door Automatic Door Operators

>> HC-R058D HOT SALE canine semen sheath for Dog Artificial Insemination Kits

>> Fully Automatic Blow Moulding Machine Plastic Bottle Making Pet Bottle Blowing Machine 4-8 Cavities

>> Factory Price Hospital Medical Diagnosis Equipment Digital Film X-ray Dry Printer

>> HEARTY RISE-Slow Jigging R III Rod fishing rod tuna beach cheap new carbon fiber fishing rods

>> First Sale Single-Person ATV Tracked Snowmobile Amusement Park Beach Buggy for Adult

>> Adult Four-Wheel Professional Wooden Skateboard/70 * 51PU Flash Wheel/7-Layer Maple Skateboard

>> Exterior Cheap Outdoor Wood Plastic Composite Flooring WPC Composite Flooring Decking Outdoor

>> Automatic Pasta Machine To Make Rice /nstant pasta making machine

>> Foska Small Cute Promotional Gift Calculator Student Stationery Portable Student Calculator