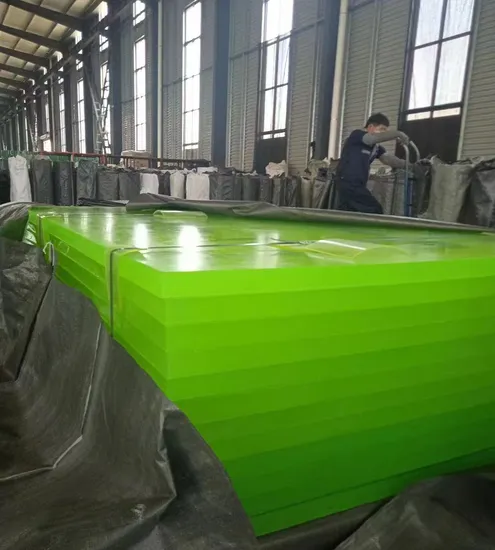

Youli Glue Spring Glue Polyurethane Elastomer PU Rod Shaft Sheet Roll

| US$3.20-3.50 | 1,000 kg (MOQ) |

Basic Info.

Model NO.

YLP 2598

Water Absorption

0.1%~0.3%

Contraction Percentage

1.5%~5.0%

Tensile Strength

51~80MPa

Hardness

20-90 Share a

Resistant

Oils Greases, Chemicals, Water

Process

Moulding Cutting

Elongation

500% More

Transport Package

Wooden Case Pr Pallet

Specification

8-500mm

Trademark

customized or no mark

Origin

Hebei, China

HS Code

3926909090

Production Capacity

100t/Month

Product Description

PU: thermosetting polyurethane elastomer for short PU, English name Casting Polyurethane, commonly known as Youli glue, spring glue, is made up of polymer polyol and different Cyanate ester reaction, chain extension, a new synthetic material between plastic and rubber.According to the different backbone structure of polyurethane elastomer, it is divided into polyether Type and Yukalac type of two kinds

Polyether-type PU rod: English name Polyether urethane. Polyether-type polyurethane occupies the main role in polyurethane, mainly because of the polyether viscosity Small and easy to operate. Polyether is better than polyester in its resilience, moisture evaporation, low temperature performance, impact strength, heat accumulation, water resistance and mold resistance .

Polyester PU rod: English name Polyester polyurethane, compared with polyether, mechanical strength, tensile strength, tear strength, sliding friction, resistance Oil properties, thermal aging, metal adhesion, solvent resistance and oxidation resistance are better than the polyether type. However, the polyester viscosity is large, and the operation is more difficult.

Characteristics: PU rod has chemical corrosion resistance, tensile strength, high elasticity, high pressure load resistance, high wear strength, strong shock absorption, tear resistance, radiation resistance, high strength, High bearing and shock oning and other good performance. High elasticity can be maintained in a wide hardness range (Shaw A10 to Shaw D75). Its excellent and unique comprehensive performance It is not available with ordinary plastic and rubber.

Application field: suitable for metallurgy, mining, petroleum, automobile, building materials, sports, heavy machinery, large stamping equipment damping pad, pad, spring, and do a variety of punching die of metal plate and pipe. Universal mechanical equipment friction, cushioning or shock absorption, is ideal for mold spring

Polyether-type polyurethane (common PU) Specific

gravity: 1.15g / cubic cm 3

Hardness: 90A

Tensile strength: 30 Mpa

Tear strength: 65 KN/m

Pull the elongation rate: 445%

Acclone asion: 0.029cm³/1.61km

Used temperature: -35~50ºC

Bearing capacity: 10.5Mpa (approximately 25% compression)

Polyester polyurethane (high wear PU) Specific

gravity: 1.25g / cubic cm 3

Hardness: 90A

Tensile strength: 53Mpa

Pull the elongation rate: 548%

Permanent deformation value: 34% (70 C 22 hours)

Acclone asion: 0.014cm3/1.61km

Use temperature: -40 to 60

Bear capacity: 10.5Mpa (approximately 25% compression)

Advantages of Polyurethane When Compared to Conventional Materials

| ...vs. Rubber | ...vs. Metal | ...vs. Plastic |

| High abrasion resistance High cut & tear resistance Superior load bearing Thick section molding Colorability Oil resistance Ozone resistance Radiation resistance Broader hardness range Castable nature Low pressure tooling | Lightweight Noise reduction Abrasion resistance Less expensive fabrication Corrosion resistance Resilience Impact resistance Flexibility Easily moldable Non-conductive Non-sparking | High impact resistance Elastic memory Abrasion resistance Noise reduction Variable coefficient of friction Resilience Thick section molding Lower cost tooling Low temperature resistance Cold flow resistance Radiation resistance |

>> Polyurea Coating for Marine Drilling, Oily Energy Places

>> Zoomlio 116 Tonne Excavator Ze1250g Hydraulic Mining Shovel Variable Swash Plate Pumps Planetary Transmissions with Axial Piston Motor Hydraulically Released

>> Wiiboox Sweetin High Accuracy Home DIY Multi Material Edible Food Chocolate 3D Printer

>> New One Rows Manual Vegetable Planter Carrot Onions Cabbage Lettuce Seeder

>> IP65 Waterproof LED Neon Flex Strip Light for Outdoor and Indoor Use

>> Universal Input 180-240VAC High Power Battery Charger 48V12A for Lithium Lead-Acid Batteries

>> Motorcycle Parts Accessories Dry Cell / Dry Battery for 12n9-BS

>> 45 Slant Bed Frame High Precison Taiwan Linear Rail CNC Lathe with Hydraulic Servo Turret Mt-400c

>> Knock out Aerosol Insecticide Spray Pest Control Killer Spray

>> Egg Cleaning and Sorting/Breaking Machine with Pasteurization Machine

>> 492L Customized LOGO Big Capacity Home Use Frost Free Four Door Transparent Lcd Fridge Door

>> Plastic Bottle Drinking Water 5L-20L 5gallon Barrel Liquid Jar Pet Preform and Plastic Cover Lid Injection Molding Machine Price

>> High quality Concrete Test Rebound Hammer - sclerometer

>> Disposable Velour Indoor Guestroom Guesthouse Hotel Slipper

>> 16 PRO Max Android Mobile Cell Phone Android 13 Smartphone Unlocked Mobile Phones

>> Hot Sale Universal Cylindrical Grinder CE Approved Sumore China Equipment Hydraulic Grinding Machine

>> Hot Sale China Manufacturer Pei Blcak Plastic Fiberholder Parts

>> American Style Customized High Quality Sanitary Vanity Set Shaker Design Grey Wooden Cabinet Restroom Furniture

>> High-Grade Color Plastic Doors and Windows Aluminum Machine Double-Sided Two Heads Seamless Welding Machine/UPVC/PVC Window Making Machine

>> Water Inlet Pipe/Plastic Hose Extrusion Blow Molding Machine

>> 40# 220V 100W AC Permanent Magnet Synchronous Servo Motor Without Brake

>> Durable High Capacity Colour Sorter Plastic Flakes Color Sorting Machine

>> Hydraulic Forging Oil Press Metal Forming Machinery

>> Good Quality Factory Manufacture Pillow Block Taper Roller Cylindrical Needle Thrust Machinery Agriculture Auto Motorcycle Ball Bearing Deep Grove Ball Bearing

>> 2022 New Style Electric Garlic Separating Selecting Machine Garlic Clove Separator Double Motor

>> CNC Plasma and Flame Cutting Machine for Metal Sheet Cutting

>> My-G057I Rechargeable Bluetooth-Like Amplifiershigh Quality Rechargeable Bluetooth-Like Amplifiers

>> Hot Solid Ink Roll Thermal Ink Roll Dikai 36mm*32mm Thermal Transfer Ribbon Hot Solid Ink Rolls

>> Scrc130b EMI Suppression Ferrite Shielding Core for 13mm USB Lvds FFC Cable

>> Alwsci 40ml Clear Glass EPA/Toc Vial Ultra Clean Vial