Disposable Food Trays Making Machine for PS Foam Hamburger Boxes

| US$150,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HLSJPS-130/170

Type

Sheet Extruder

Plastic Processed

Polystyrene

Product Type

Extrusion Molding Machine

Feeding Mode

One Feed

Assembly Structure

Separate Type Extruder

Screw

Twin-Screw

Engagement System

Full Intermeshing

Screw Channel Structure

Deep Screw

Exhaust

Exhaust

Automation

Automatic

Computerized

Computerized

Capacity

370-500kg/H

Sheet Thickness

1.5-6mm

Sheet Width

Double Sheet 1300mm

Foaming Rate

11-25times

Transport Package

Standard Packaging

Specification

35x4.55x3m

Trademark

Holin

Origin

China

Production Capacity

5sets

Packaging & Delivery

Package Size

4000.00cm * 450.00cm * 300.00cm

Package Gross Weight

32000.000kg

Product Description

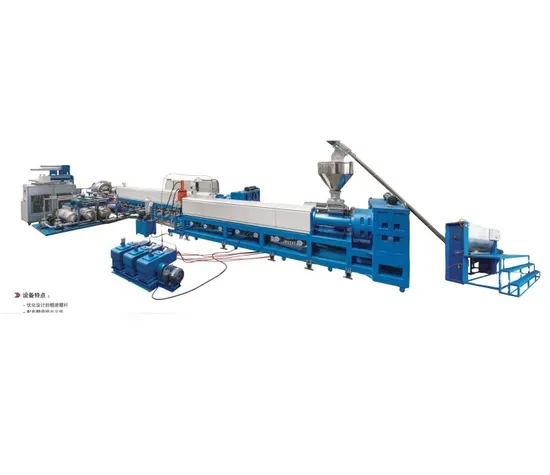

Introducing the dynamic Plastic Sheet Extruder, on sale now for all your versatile food packaging needs, straight from the industry leader, Hangzhou Holin Plastic Machinery Co., Ltd.1.Production Process

Experience the advanced Expand Polystyrene Sheet Extruder, a dual-screw marvel that utilizes gas foaming technology to produce high-quality sheets.

Harnessing the power of General Purpose Polystyrene (GPPS), this machine injects a gas foaming agent throughout the production process. The sophisticated Winder ensures the sheet is expertly wrapped into rolls for ease of use.

2.Product Use

Our sheets are perfect for thermoforming applications and can be transformed into fast food containers, egg trays, and disposable bowls. Thanks to their superior heat and sound insulation properties, they are also ideal for architectural uses like decorative boards and car interior ceilings.

3.Advantages

1) Equipped with a precise and robust screw design for enhanced performance.

2) Utilizes precision-engineered components for reliable operation.

3) Engineered to ensure no leakage, maintaining product integrity.

4) Trusted brands like Mitsubishi, Siemens, and Lewa provide superior quality parts.

5) Delivers sheets with even thickness and an impeccably smooth finish.

6) Capable of saving diverse technical parameters for customizable production.

7) Features advanced PLC control for seamless operation and efficiency.

MODEL PROVIDED

4.Technical Parameters

| Foam Polystyrene Sheet Extruder Main Techincal Parameters | ||||

| Style No. Parameters | Unit | HLSJPS-120/150 | HLSJPS-100/130 | HLSJPS-130/170 |

| Capacity | kg/hr | 370-500 | 250-310 | 450-550 |

| Thickness | mm | 1.2-6 | 1.2-6 | 1.2-6 |

| Width | mm | 1000-2000 | 1000-2000 | 1000-1500 |

| Foaming Ratio | times | 11-30 | 11-30 | 12-25 |

| Linear Speed | m/min | 5-40 | 5-40 | 5-40 |

| Mounted Capacity | kw | 540 | 250 | 625 |

| Pressure of Cooling Water | mpa | ≥0.2 | ≥0.2 | ≥0.2 |

| Cooling Water | t/h | 18 | 13 | 20 |

| Compressed Air Pressure | mpa | 0.7 | 0.7 | 0.7-0.9 |

| Compressed Air Amount | CBM/min | 1.5 | 1.1 | 2 |

| Butane Injection Pressure | mpa | 1 | 1 | 1 |

| Weight | ton | 22 | 18 | 32 |

| Installation Size | m | 35*4.55*3 | 33*5*3 | 40*4.5*3 |

5.After Sales Service

1) Our expert engineers are dispatched to your factory, ensuring flawless installation and comprehensive training.

2) Enjoy a one-year warranty on main machine parts, with continued support and reasonably priced parts available afterward.

3) Access our dedicated 24-hour online support service for all your needs.

6.Photos

>> 30-40HP Mini Farm Wheel Tractor Cultivator

>> 16PCS Sequins Lure Feather Treble Hook Combo Metal Spoon Fishing Lures Set

>> Senmo Mult-Use Grinding Machine 2m9120A Universal

>> Kitchen Equipment 750W Professional DC Motor Immersion Hand Blender (HM-750W)

>> Multi Cavity Customized Riha Offer Mold Plastic Molding Injection Mould in China

>> China Recycling Rotary Screener Use for House Waste Sorting with Factory Price

>> Laboratory Consumables 0.1ml 0.2ml 96 Well Full-Skirted/Half-Skirted/Non-Skirted PCR Plate

>> Nature′s Choice: Biodegradable, Disposable Outdoor Tablecloths

>> High Quality Factory Price Turret Vertical Milling Machine

>> Wholesale Qhm Production Directly Gold Glitter Embroidery Thread

>> Custom Print Plastic Aluminium Foil Potato Chips Back Side seal Packaging Bag for fries Snacks/Cheese rings

>> Free-Standing Vertical Lift Steel Height Adjustable Monitor Mount Stand with Glass Base TV Stand

>> Garden Tools Steel Claw Hammer Family Hardware Tools

>> Custom Wireless Wall Socket Switch for Smart Homes

>> CNC Vertical Lathe Hydraulic Tool Holder Metal Cutting

>> Waste recycling coconut husk crusher sawdust making machine

>> High Pressure Steel Farm Pumps Cast Iron Electric Motor Peripheral Qb60 Irrigation Water Pump

>> Acoustic Damping Foamed Aluminum Foam for Studio Acoustics

>> Rheometer Materials Testing Machine for High-Quality Rheological Testing Solutions

>> Online shopping high quality aluminum facades decorative expanded metal mesh

>> Personalized Shopping Mall Art Piece Custom Vase

>> 4200W Ultrasonic Welding Machine for Making Scourer Pad Kitchen Dish Washing Sponge

>> Patio Retractable Waterproof Roof PVC Awning Pergola

>> Auto Folding Portable Trampoline Park with Trailer Amusement Park Equipment

>> Genuine sheep skin top grain fine quality leather wallet wholesale top lining customised england style RFID OEM ODM

>> Glass Hanging Decoration for Different Xmas Tree

>> Hot Multi Cavity Riha Offer Moulding Customized Mold Plastic Injection Molding Mould

>> PP body kit For Honda civic type-R front rear bumper side skirt spoiler

>> Factory Outlet ICU Bed Electric Hospital Bed Electric 5 Functions Medical Bed CE ISO Verified

>> Cutting-Edge Injection Moulding Equipment for Cost-Effective Plastic Chairs