Universal Tool Grinding Machine 2M9120A 2M9125A MA6025

| US$5,000.00-10,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

2M9120A 2M9125A MA6025

Processing Object

Curve

Abrasives

Grinding Wheel

Controlling Mode

Artificial

Automatic Grade

Automatic

Cylindrical Grinder Type

Universal Cylindrical Grinder

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Max.Swing Diameter Over Table

200mm

Max.Work Piece Length

500mm

Max. Load

10kg

Total Power

2.905kw

Transport Package

Wood Case

Specification

CE ISO9001 SGS ROHS

Trademark

WELLON

Origin

China

HS Code

8460199000

Production Capacity

50 PCS/Month

Packaging & Delivery

Package Size

1900.00cm * 1400.00cm * 1630.00cm

Package Gross Weight

1700.000kg

Product Description

Product DescriptionDetailed Photos

Product Parameters

Performence Features:

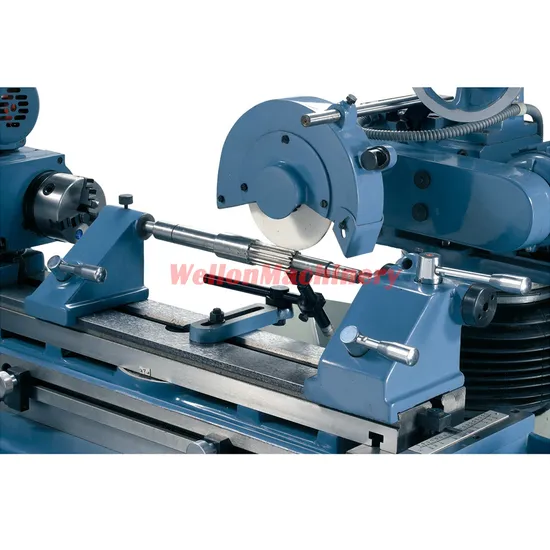

The multi-grinder ranges from external and internal cylindrical grinding to taper grinding.

It also allows tool grinding, (sharpening of cutters reamers, and turning tools) and is suitable for light surface grinding jobs.

1.The machine combines the functions of universal external grinder and universal cutter grinder.

It performs with super quality such as grinding internal cylindrical and taper workpiece, flat, vertical and inclined surfaces

and slots.It can also readily undertake sharpening cutters such as various milling cutters, reamers, pinion cutters and lathe

and supplied upon ordering.It can also be used for sharpening straight fluted hobs drill,etc.

2.The wheelhead spindle of the machine runs perfectly well, its adjustment are easy.The worktable drive many be either

hydraulic or manual controlled hydraulic serve.

3.You would find it an indispensable equipment for your tool shop, repair shop, research units and small and medium scale

machinery plants.

Technical parameter:

| Model | 2M9120A | 2M9125A | MA6025 |

| Max. swing diameter over table | Φ200mm | Φ250mm | Φ250mm |

| Max. work piece length | 500mm | 500mm | 650mm |

| Size for surface Grinding | 300×125mm | 200×50mm | 350×100mm |

| Size for cutter grinding | Φ200×500mm | Φ250×500mm | Φ270×545mm |

| External grinding | 5-50mm | 5-50mm(MT2) 5-100(MT4) | / |

| Internal grinding | 10-50mm | 10-50mm | / |

| Max. weight of work piece | 10kg | 10kg | 12kg |

| Work head spindle taper | MT2 | MT2/MT4 | ISO .NO.50/M.T.NO.2-5 |

| Work head spindle speeds | 110,200,300rpm | 110,200,300rpm(MT2) 60,,9,120,175,235,345rpm(MT4) | 280rpm |

| Work head swivel | ±90º | ±90º | ±360º/±15º(Tilt) |

| Max. traverse of the wheel head | |||

| Slide Vertical/Cross | 200/200mm | 250/200mm | 250/230mm |

| Wheel head spindle speeds | 2500rpm | 2500rpm | 2700,4000,5500 rpm |

| Speed of wheel head up-down travel | |||

| Internal grinding spindle speed | 13500rpm | 13500rpm | / |

| Longitudinal table travel, hand control | 480mm | 480mm | 400mm |

| Table travelse speed | 0.1-6m/min(hydraulic) ≤7m/min(Servo drive) | 0.1-6m/min(hydraulic) ≤7m/min(Servo drive) | Manual |

| Max. swivel of table | ±45º_-30º | ±45º_-30º | ±45º |

| Tailstock taper/Sleeve travel | MT2/14mm | MT2/14mm | MT2 |

| Total power | 2.905kw | 2.995kw | 3.15kw |

| Overall dimensions | 1520×1133×1173mm | 1520×1220×1360mm | 1340×1320×1320mm |

| Size of case | 1900×1400×1630mm | 1860×1360×1590mm | 1820×1550×1640mm |

| Gross Weight/Net weight | 1700/1285kg | 1700/1385kg | 1300/1100kg |

| Standard accessorise | |

| Coolant equipment | 1Set-Left tailstock |

| 6Piece-Grinding wheel | 5Set-Driving dogs |

| 1Set-Internal grinding wheel head | 1Set-Wheel dresser |

| 1Piece-Extended grinding wheel spindle | without diamond |

| 1Set-Cutter head | 3Piece-Wheel pullers |

| 1Set-Ttree-jaw chuck | 2 Piece-Vee-belt |

| 1Set-Plane grinding | 1Set-Wheel balancing stand |

| 1 Piece-Centre | 1Piece-Flat belts |

| 1Set-Tooth rest | 3Sets-Flanges for grinding wheel |

| 1 Piece-Centre | 2Piece-Centering technical sleeves |

| 2Sets-Wheel guards | |

Company information

Packaging & Shipping

FAQ

1: What's your main products of your company?

A : We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center,

Double Column,Machining Center,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper

machine and so on .

2:What kind of controlsdo you use on machines?

A :Siemens,GSK ,Fanuc etc. You can choose according to your requirements .

3. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

4 : How can I choose the most suitable machines ?

A : Please tell me the model or parameter you are interested in, we can provide you with the best price and quality.

You can also send us product pictures and we will choose the most suitable machine for you.

5 : Do we receive any updates while machine is in the manufacturing process?

A : Of course. The progress of the machine will be updated regularly and sent to you.

>> Manufacturer Thermoplastic PVC Injection Molding Machinery

>> Wholesale Customized DMX XLR Powercon Cable 3pin 5pin XLR Power Combo Cable for Stage Light Audio

>> Digital Painting Coating Thickness Gauge

>> 8000L Per Hour Beer Yeast Disc Stack Centrifuge Separator with Flow Meter

>> HC-A026 128 elements Color doppler portable linear USB ultrasound convex probe for laptop

>> CNC Machining Aluminum Parts for Gearbox

>> Automatic Pipe Spool Prefabrication Line Fixed Type

>> Heavy-Duty Single Cone Ribbon Mixer Machine with Efficient Mixing Technology and Easy Maintenance

>> Free Shipping Machinery Diesel Pig New Animal Feed Processing Food Feed Pellet Machine for Animal Poultry

>> high quality car accessories HID Xenon headlamp headlight for audi A3 head lamp head light 2017-2020

>> Safety Race Car Round Tube Latch Style Window Net Installation Mounting Kit

>> Auto Boot Vamp Shaping Machine/Shoe Shaping Machine

>> High Quality 6n40A Combine Grind Mini Rice Mill Corn Sheller Machinery

>> Smart Electric Tricycle for Cargo with Efficient Energy Use

>> Smart Bluetooth Bracelet Viqee Brand

>> New Design Hand Held Multifunctional Tillage Tiller Machine

>> Welding Frame Fancy Veneer Hot Press Machine for Plywood Making

>> YADA Disposable 140mm Wooden Spoons for Ice Cream Natural Food Grade Eco-Friendly Biodegradable

>> Customizable Full Servo Baby Pull-up Pants Manufacturing Machine

>> Farm Use Small Poultry Feed Pellet Making Machine with Capacity 50-200 Kgs/H

>> Hot Sell Personalized Blank Metal Hat Cap Keeper Bag Holder Clips for Travel Leather Custom Design Strong Magnet PU Leather Hat Clip

>> Cost Plastic Recycling Machine /Recycling PP PE Washing Line

>> Quality Inspection Agent International Shipping Air Freight Courier Service China to Malaysia

>> 3 Stage 600gpd Quick Fitting Filter Cartridge Reverse Osmosis System Water Purifier

>> ID Badge Holder Lgbt Pride NHS Rainbow Striped Lanyard for Keys

>> 9.6 EER Inverter 2P 18000Btu 48V DC Wall Mounted On Grid Solar System A/C

>> R108A Classic Creative Record Player Speaker Multi Function Built-in Speakers Vinyl Pickup Vinyl Records Player Gramophone

>> Rebar Steel Bar Bender Bar Iron Metal Bending Machine Manual for Rebar Small Diameter Size Rebar Spiral Bender Arc Rebar Bending Machine

>> Warehouse Stacker Crane Asrs Automated Warehousing Rack System

>> Hot Product Bamboo Cutting Board Square Durable Cheese Board Customizable Logos Bamboo Cheese Board