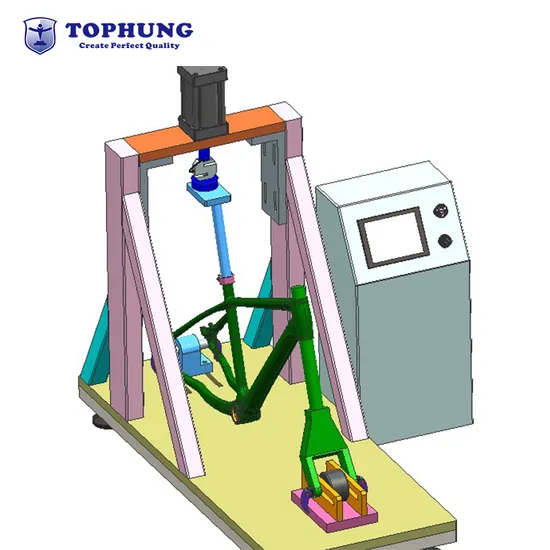

ISO-4210 Frame - Vertical Force Fatigue Testing Machine

| US$2,300.00-3,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

ISO-4210

Force Load Cell

High Precision 2000n Load Unit

Control Mode

Touch Screen +PLC Control

Transport Package

Wooden Packing

Specification

1050*500*950mm

Trademark

Tophung

Origin

Jangsu, China

HS Code

9024800000

Product Description

ISO-4210 Frame - Vertical Force Fatigue Testing MachineMachine description The ISO-4210 Frame - Vertical Force fatigue tester is designed to test the vertical durability of the risers of bicycle frames during production. In accordance with the ISO 4210 standard, the frame is quickly installed and fixed on the special test fixture in its normal riding posture, and the test fixture is installed on the riser instead of the saddle tube, and is clamped outside the rear flat fork. A cyclic dynamic force of 1200N downward pressure is applied to the test fixture of the saddle tube in the vertical direction. The design of the testing machine is modular, the specifications and functions meet the requirements of the specification, and the operation is safe and easy

Main functions 1 The color touch screen LCD+PLC display control, all test conditions are directly input by the LCD touch screen panel;

2 The strength of the test is displayed immediately;

3 PLC program can set the test frequency and test times;

4 The power source adopts 6kg compressed air source, stable operation, low noise;

Product Description

| Model | ISO-4210 |

| Name | Frame - Vertical force fatigue testing machine |

| Maximum power | Within 2000N, the compressed air pressure can be adjusted according to the test requirements |

| Force load cell | High precision 2000N load unit |

| Control mode | Touch screen +PLC control |

| Power display accuracy | +/-1% |

| Test speed | 1-3 times/second, can be set digitally |

| Counting digits | 0-999999 times |

| Table area | 600×1300mm (width × length) |

| Machine power supply | Three-phase 220, 50/60 or specified |

| Appearance size | 1300×600×800 mm (W×D×H) |

| Machine weight | About 200Kg |

Company Profile Suzhou Tophung Machine Equipment Co., Ltd. was founded in 2007 and is a professional manufacturer of quality testing machines that integrates research and development, production, sales, and service. For over a decade, the company has been committed to providing excellent testing instruments and overall quality testing solutions for professional material testing, structural testing, and finished product testing to our customers. Tophung products are widely used in industries such as metal materials, new composite materials, solar photovoltaic new energy, wires and cables, automotive parts, plastic products, etc.

Our Mission:

Provide professional testing project to help customer to create perfect quality.

Our Vision:

Continued innovation, leading Tophung towards the world.

Our Values:

Achieve Max benefits for customers.

Our Commitment:

Dedication to improve service and exceed customer expectations.

Our Team:

Tophung has a group of skilled scientific and technological talents, a professional sales team, and a comprehensive after-sales service system, with rich industry testing experience.

Customer Stories The equipment developed by Tophung has achieved industry-leading performance, creating value for customers and society while collaborating with German companies such as "CADIS" and TUV, Tianxiang, and Huace. Tophung has long served outstanding enterprises both domestically and internationally, growing together with users and exploring product quality control solutions. It has rich industry testing experience and has been highly recognized by many users in the industry. In 2014, it was awarded the title of "Quality Trustworthy Enterprise" by the Jiangsu Provincial Quality Supervision and Management Center.

Certifications Tophung Company takes the development of national scientific and technological infrastructure as its responsibility, focusing on the research and development and production of scientific instruments and equipment. At present, Tophung has 32 authorized patents and has also obtained ISO quality management system certification and EU CE certification. The main series of testing machines produced by Tophung have obtained national patents and all have independent intellectual property rights.

Services If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation manual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by customer.

1. Pre-service

--24 Hours online service for your consult.

--Help choose right model, and a series of service, person, advise.

2. Middle service

--Give you best offer

--Provide discount for many sets order

--Do customer's request:

--Choose payment term you convenience.

--Promptly production and delivery, inform you in time.

--Can provide invoice value as you like to decrease your tax.

3. After sale service

--1 year warranty service and all life maintenance.

--Technical Engineer are available for oversea training.

--Free change for some parts

--Remote control technical consult

--Maintenance plan

4. Commitment

We will sign a letter of commitment while we sign the contract, which will improve your confidence to us.

5. Good Packaging

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

FAQ

Contact information:Dear customer,If you need our testing machines, please send us inquiry without any hesitate !-------------Suzhou Tophung machinery equipment Co., Ltd.

>> High Quality Chinese Truck Bus Auto Spare Parts Yutong Diesel Engine Fuel Injector 1112-00214

>> ELK Supply European Type Single Double Girder Electric Wire Rope Hoist 5ton

>> High Quality Truck EQ430 Clutch Pressure Plate Clutch Cover Assembly

>> Open Woven Heavy Duty Fire Flame Retardant UV Resistant Vinyl Coated Polyester Construction Safety Barrier Cover Pool PVC Mesh Fabric for Screens Tarps

>> Epidemic Relief Blankets Picnic Blanket Easy to Carry Dual-Sided Ultra-Soft Pink Plaid

>> Commercial 30 Tonnes Per Day Maize Flour Mill Corn Semolina Posho Milling Machinery for Africa Food Fufu Bugari Ugali Price in 2024

>> New Design High Precision Factory Price Metal Laser Cleaning Machine 1000W 1500W 2000W 3000W for Metal Aluminium Stainless Carbon Steel

>> Quality Guarantee Cheap Price LLDPE 9.6 Feet Single Sit on Top on Sea Fishing Kayak

>> RF Coaxia RP- TNC Female to N male Adapter

>> Automatic Wire Winding Machine with Insulation Maunally

>> Car accessories Car hood New for audi A4 B9 refit iron transparent engine hood

>> Cheap Price HDPE/HDPE ISO 1200X1000 Heavy Duty Rack Plastic Pallet for Warehouse

>> Agricultural Machinery Low Breakage Ly-20000 Peanut Shelling Machine Peanut Sheller

>> Good Quality Children Toys Making Machine / Plastic Injection Machine

>> Hst-Q100b Metallographic Automatic Cutting Machine

>> Vertical Milling Machine Fanchen Vertical Milling Machine Factory

>> SGS Certificate High Purity 99.9% 99.8% 99.7% Lead Ingot for Battery

>> Fravimetric Blender PP Nonwoven Fabric Machine

>> All-Inclusive Ocean Shipping Customs-Cleared Customized DDP China-Europe Shipping Plans

>> Taijia ZD310 ferroscan integrated rebar scanner detector iron rebar locator

>> Toyo-Intl High Quality 6: 1 Ea Type 4txm Round Sling

>> Original Factory Durability Dispersing Mixer Semi-Automatic Silicone Sealant Making Machine with Fast Curing Speed

>> Medical Flame Retardant Disposable Hospital Cubicle Curtains

>> 4 Head 5star Logo Name Computerized Embroidery Machines Cap T-Shirt Computer Embroidery Machine Prize in Bangladesh

>> Metal Horse Saddle Box Rack Horse Box Trailer Float

>> Best Gummy Jelly Candy Depositing Machine, Making Machine

>> Hot selling 4G LTE Modem Signal Booster Antenna Wifi USB Dongle Antenna Outdoor 5DBI 4G Router LTE Antenna SMA male rg174 1.5m

>> Wholesale Unique Clear White Black Pink Lip Gloss Containers Lip Gloss Tubes Custom Logo Empty Lipgloss Tube

>> Gold Wedding Royal Throne King Chair/ Sofa Chair/ Throne Chair

>> Car Window Pdlc Glass Dimming Blue Smart Eva Film For Cars With Remote Control