Automatic Hot Sale Yarn Packaging Machine/Package Baler

| US$80,000.00-100,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

Qp10

Spinning Method

Ring Spinning

Processing Material

Cotton

Producing Process

Spinning Equipment

Certification

CE, ISO9001: 2000

Warranty

12 Months

Customized

Customized

Condition

New

After-sales Service

7/24

Yarn Packages/ Bag

12-15 Packages/Bale;8 Packages/Bale for Open-End S

Palletizing

4-5 Bales / Layers, 10-15 Layers

Packing Tape

PP Tape Recommended, Width 9-12mm

Precision

25kg

Transport Package

Wooden Box

Specification

13x5m

Trademark

Qingdao Hongda

Origin

China

HS Code

84454010

Production Capacity

100pieces/Year

Product Description

24h Online Customer ServiceProduct Description

Qingdao Hongda Textile Machinery Co., Ltd (here after referred to as QDHD)is the subsidiary company ofJingwei Textile Machinery Co., Ltd. It is a large-scale backbone enterprise of textile machinery manufacture,as well as an important manufacturing base for carding machinery and auto-winder.

The Technology Center of QDHD is certified as the National Technology Center. Blowing-Cardingmachinery wins the First-Class Scientific and Technological Progress Award issued by China Textile IndustryAssociation and is the promotion program in The Ninth Five-Year Plan of the State Science and TechnologyCommission. The three leading products of QDHD-Carding Machine, Blowing-Carding Machine and Auto-winder, have all passed the ISO9001 quality system authentication, winning QDHD the honor of "PioneerEnterprise of National Quality Control".

Facing the new situation, Qingdao Hongda Textile Machinery Co., Ltd will be committed to continuouscontribution to the development of Chinese textile machinery, the technological progress of the Chinesetextile industry and the improvement of its international competitiveness by executing new initiatives andadvancing with times.

Application

Yarn package produced by auto-winder, open-end spinning, vortex spinning, twister and other equipment.

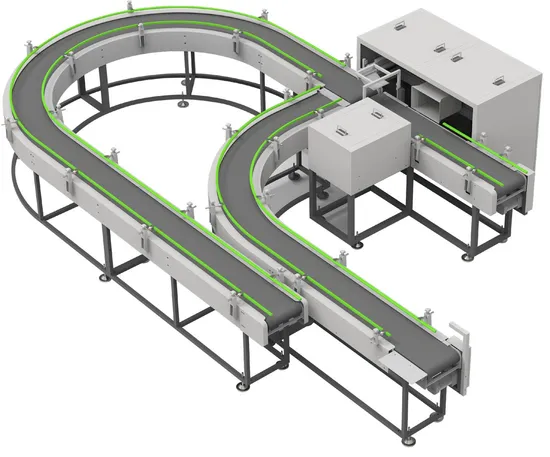

Main component units

1. Feeding unit 2. Visual unit 3. Weighing unit 4. Counterweight unit 5. Overturn unit 6. Laminator unit 7. Bagging unit 8. Seam unit 9. Tying unit 10. Palletizing unit

Output up to 2000kg / h (12 yarn packages / bag) .

The varieties can be changed quickly in 3 ~ 5 minutes, to meet the requirements of users for multi-variety baling.

Humanized design for easy and convenient operation, the workers are able to operate after simple training.

Small area occupation and high configuration flexibility, this equipment is suitable for all spinning mills.

High efficient and maintenance-free palletizing machine .

High efficient and maintenance-free laminator machine saves the later cost.

It adopted the innovative circulating counterweight mechanism to save the time of all warehouse action. The yarn packages selected by the counterweight system can be sent to the next process according to the speed set in debugging, and the yarn packages which are not selected can be quickly pushed into the return conveyor.

This circulating counterweight system can feed a yarn package again in 1.2 seconds to efficiently complete the whole counterweight process and will never "die".

The dynamic yarn package overturn mechanism moves a step to the forward direction of the conveyor belt while realizing overturn. The pushing in and out action of yarn package is dynamically realized during the movement of the conveyor belt, which eliminates the yarn package wait during overturn, and realizes the continuous .

Different from the traditional cylinder-pushing mode, it adopts innovative application of belt feeding design with simpler and more reliable structure that realizes the continuous production without waiting in the whole laminating process to greatly improve the lamination efficiency up to 2 seconds / yarn package.

FAQ

(1) Q: Are you a manufacturer or agency?

A: We are a professional manufacturer specialized in producing textile machine and was established in the year of 1920, so we have been engaged in the manufacture of textile machinery for one century. We have our own International Trade Department, so that we can better understand customer's needs and offer a reasonable price.

(2) Q: Is the price offered changeable?

A: Of course, we offer reasonable price and the price is changeable according to purchasing amount. changed according to purchasing parameter.

(3) Q: How about the quality?

A:The main component is imported. Key parts are research and design by ourselves.

(4) Q: How about the after-sale service system?

A: Our engineers available to service overseas to provide professional technical support.

(5) Q: Are you available for on-the-spot invitation?

A: Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

>> Factory Bathroom Touchless Auto Brass Wall Mounted Infrared Sensor Water Electric Faucet Taps

>> Multifunctional Metal Capacitance Mobile Phone Touch Screen Stylus Pen Promotional Gift

>> Animal Egg Twisting Machine 12-16 Eggs Blind Box Toys Delicate Gift Creative Egg Surprise Girl Party Animals Twisting Children

>> Aluminum Swimming Cylinders (200 Bar)

>> Brass Swing Check Valve - 3800 (Light type, standard bore, PN16) - Ayron Brand

>> China Manufacture Wholesale Price Passenger Home Glass Elevator for Center Market

>> 450mm Cardboard Packaging Strip Shredder Box Shredding Cross-Cut Carton Shredder Machine

>> Remote Control Helicopter Hand Control Aircraft Dual Mode for Children Outdoor Toys with LED Light Infrared Sensor Flying RC Mini Helicopter

>> High Advanced Djm Vertical Colloid Mill 7t of Juice Lines

>> Double Spiral Notebook Hardcover Diary Notebook for Promotional Gift (SNB107)

>> High Speed OEM China Esy800m CNC Single Spindle Turning Machine

>> GGG40 sand casting 11627788422 exhaust manifold

>> Hot Selling Multicolor 68cm*42cm Lotus Acupuncture Needle Yoga Mat with Pillow

>> HDPE PE PP Bucket Drum Barrel Blowing Machine 12L ~ 18L (PXB70A-1PT)

>> Eg8143A5 Fiber Modem Gpon Ont CATV 1ge 3fe 2.4G WiFi ONU Gpon ONU 8143A5 FTTH Modem

>> Innovative Mpp Power Pipe Solutions for The Needs of Global Industry.

>> 50" Webos Serie Plastic Base Thin Frame OLED AI-Powered 4K Android TV Remote

>> Multilayer Stainless Steel Spot Welding Woven Wire Mesh Filter Disc Pack

>> SMT JUKI 510 NOZZLE For KE-2010 2020 2050 2060 2050R 2055R 2070 2080 3010 3020 / FX-1 FX-1R FX-2 FX-3 FX-3R Machines 40025165 for pick and place machine

>> High-Performance Soundproofing, Thermal Insulation, Energy Saving Clear Low-E Vacuum Glass for Windows, Walls, Roofs, Refrigerators and Cars

>> Rock Hammer Mill Soil Hammer Crusher Stone Gold Ore Hammer Mill Crusher

>> Block Brick Making Machinebrick Making Machines in Ugandafire Brick Machine Making Automatic

>> Spray Multi Cleaner with 4 Heads Plastic Brush Sponge Scourer Window Wiper

>> Truck Brake Parts Type 1 Hole 10 Teeth 79365 Automatic Slack Adjuster

>> Hebei Aluminium 304/316 Perforated Metal Panel Perforated metal wire mesh

>> Tmr Tractor Power Horizontal Feed Grinding Mixer for Livestock

>> Plastic Recycling Pet Bottle Flakes Crushing Washing and Drying Machine

>> Non-Standard Customized Products of Cemented Carbide

>> 88-22528 PCS Egg Poultry Farm Incubator Fully Automatic Hatching Machine for Chicken Duck Goose Quail Common Use

>> Kinematic Viscometer for Asphalt | Bitumen testing