High Performance Heavy-Duty Vertical CNC 3 Axis Machining Center with High-Speed Operation

| US$1,500.00-10,000.00 | 1 Piece (MOQ) |

Basic Info.

Process Usage

Metal-Cutting CNC Machine Tools

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.02~0.03(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE, RoHS

Condition

New

No. of Spindles

Single

Type

Vertical

Weight (T)

17

Table Travel (Z) (mm)

800 mm

Positioning Accuracy (mm)

0.01 mm

Repeatability (X/Y/Z) (mm)

±0.0075

Range of Spindle Speed(r.p.m)

1 - 6000 r.p.m

Max. Table Load(Kg)

1800 Kg

Min. Time of Tool Change(S)

2

Tool Magazine Capacity

24

Voltage

220V/380V/415V

Machining Capacity

Heavy Duty

Rapid Feed Speed(mm/Min)

1 - 20000 mm/Min

Dimension(L*W*H)

5300*3900*3300mm

CNC Control System

GSK

Transport Package

Wooden Packages

Specification

1

Trademark

DX Blast

Origin

China

Product Description

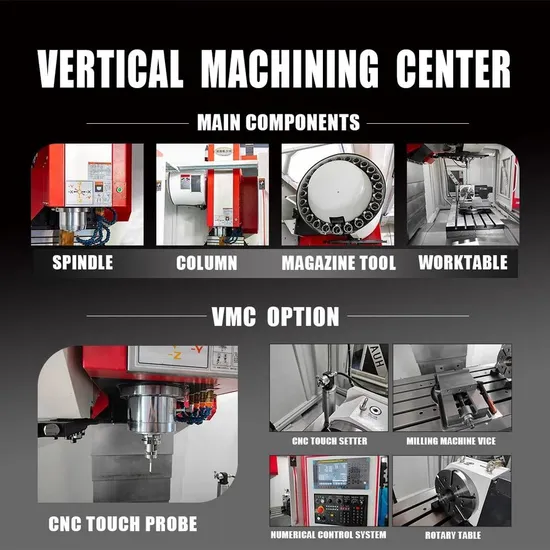

PRODUCT DESCRIPTION The vertical machining center has been developing for more than 150 years. For years of development, the vertical machining center has become a multi-functional machine with high precision, high efficiency and so on. A vertical machining center is a machine tool which is ideal for complex metal processing. Therefore, it's very popular among processing industry. Let's know more about the vertical machining center!Vertical machining, which is also known as milling, uses rotary cutters to remove metal from a workpiece. With a vertically oriented spindle, the tools sticks straight down from the tool holder and generally cut cross the top of a workpiece. CNC vertical machining center can be applied in machinery manufacturing industries with high precision and mass production requirements, such as aerospace, automobile, instrumentation, light and textile, electronic and electrical, mold making, handicrafts, etc. Vertical Machining Center is suitable for processing workpieces with complex shape, high accuracy & precision and multiple procedures.Advantages of VMC (Vertical Machining Center) 1. Operator-Friendly - Time Saving The user-friendly CNC controls make programming simple, and the design of the machine makes the workpieces fixture more easily; therefore, operators would spend less time on setup and programming. 2. Space Saving

vertical machining center occupies only about 1/3 floor space. Because VMC could save lots of space, CNC vertical machining center is ideal for small companies.

3. Higher Productivity

Automation integration boosts the productivity of a VMC by decoupling setup procedures from the machining process through automation.

4. Less Expensive than HMC

The initial investment is lower than horizontal and you can save costs in your production as well.

| Vertical Machines vs. Horizontal Machines | |

| CNC vertical machining center | CNC horizontal machining center |

| Advantages * Cost-effective * Easy to operate and maintain * Doesn't Require Extensive Facility Disadvantages * Hard to handle high weight projects * Lower production output than HMC * Lower strength motor than HMC | Advantages * Perfect for complex projects * Faster processing * High Rigidity Disadvantages * Expensive * Bigger and heavier * hard to monitor during processing |

Company Profile

>> sponge iron powder briquette machine /sponge iron fines ball press machine / sponge iron briquetting machine

>> Outdoor folding stainless steel portable burning wood camping stove

>> 8 Inch Wood Salt Pepper Grinder Shakers Set With Adjustable Ceramic Rotor

>> Large Span High Strength Concrete Pull Mold Machine

>> Luxury Gold Metal Marble Dinner Room Furniture Set Dining Table for Kitchen

>> 4K Laser Projector Smart Board with Projector HD LED Projector on Sale

>> High Quality Healthy Snack Freeze Dried Vegetable Fd Garlic Flakes

>> Custom Wholesale Cotton Flat Brim Corduroy Baseball Snapback Hat Sport Snapback Cap

>> Esun Lint Free Disposable Cleaning Mop Pads for Home Use

>> High-Efficiency Washbasin Maker - up-230 Plastic Basin Injection

>> Hotel Disposable Custom Mini Small Bottle 60ml

>> Taijia OGM series Oval Flow Meter Japan Types Of Flow Measurement

>> Tire Crusher Recycling Machine Granulator Washing Machine Line

>> Chima 13500lb Winch for Waterproof 12V CE Certificate Hot Sale Products

>> Poly/Cotton Scrub Suit Short Sleeve

>> Nylon Spandex Jacquard Printed Fabric for Women Dress

>> Customized 6-40ton Heavy Object Moving Machine Skates Cargo Trolley

>> Heavy Duty 2021 Year China Brand Sanny 43m Construction Concrete Pump Trucks

>> Egg Tray Machines for Making Egg Trays with Dryer for Manufactures

>> Tuya WiFi Smoke Detector Sensor

>> China Wholesale OEM Logo Microphone Shape USB Flash Disk 2.0/3.0 2GB 4GB 8GB 16GB 32GB 64GB 128GB Memory Stick Pendrive USB Flash Drive for Laptop

>> Liya 5.8m 19FT Fishing Boat Fiberglass Panga Boat for Sale

>> Nonwoven Disposable Epilation Strips & Rolls Depilatory

>> Sqmg Automatic 5.5 7.8 Cbm Machine Car Betonmischer Self Loading Cement Concrete Mixer

>> Heavy duty Carbon steel Expanded metal mesh for walkway

>> RSQ7 Style PP Body Kits Front Bumper For 2012-2015 Audi Q7 Upgrade RSQ7 ABS Car Grille Flog Lamp Grille Bumper Trims Body Kits

>> Hot selling laminated custom logo zip lock flat bottom chocolate plastic packaging bag

>> PU Folded Men Mini Wallet Open Cash Card Pocket Coin Colletion Part

>> Short High Carbon Lure Spinning 4-section Fishing Rod

>> Hot and Cold Dual Control Robinet Brass Wasserhahn Bathroom Wash Basin Faucet