Auto Parts Mold/Plastic Products/Hot Runner Mold/Insert Mold

| US$2,000.00-100,000.00 | 1 Piece (MOQ) |

Basic Info.

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Plastic Material

PC

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

UG

Installation

According to The Injection Molding Machine

Standard

DME

Customized

Customized

After-sales Service

Provided

Number of Forming Cavities

According to The Customer′s Requests

Dfm

According to The Customer′s Requests

Moldflow

According to The Customer′s Requests

Material

Iron

Transport Package

Wooden Box

Specification

According to mold

Trademark

Yidemold

Origin

Changzhou

Product Description

Product Parameters| Injection mold commonly used steel information | ||

| P20 | HRC27-30 | Conventional parts do not have too many requirements for product surface and mold life |

| 718HH | HRC33-38 | Conventional parts have certain requirements for product surface and mold life |

| 2738HH | HRC36-40 | Conventional parts have high requirements for product surface and mold life |

| NAK80 | HRC34-40 | Transparent parts have high requirements for product surface and mold life |

| 1.2343ESR | HRC48-52 | Transparent parts have high requirements for product surface and mold life |

| 1.2344ESR | HRC48-52 | The hardness of the product is very hard and there are certain requirements for the life of the mold |

| H13 | HRC48-52 | The hardness of the product is very hard, and the mold life has higher requirements |

| Professional High Precision Plastic Injection Mould Factory | |

| Mould material | P20, 718, NAK80, S316H |

| Hardness of steel | Vacuum quenching, nitride, hrc41-47, hrc46-50, hrc60 |

| Mould base | LKM, HASCO,DME,YANXIU |

| Mould cavity | Single / Multi |

| Runner system | Hot / Cold |

| MoInjection machies equipments | According to product precision to choice the different injection machine. |

| Inspection | 100% inspection by QC, QA before shipping. |

| Fast mould design | Can be within 5-7 working days after getting customer's drawings |

| Lead time | Plastic moulds : 4-8 weeks after getting the mould design confirmation |

| Mould testing | All of the moulds can be well tested before the shipments. Videos for moulds trial running are available. |

| Minimum order | Small orders for injection moulding can be accepted |

| Production capacity | 10 sets/month |

| Mould life | 30-1000K PCS |

| After sales service | Available by our staff with more than 10 years of working experience in this field |

Company Profile

Product Description

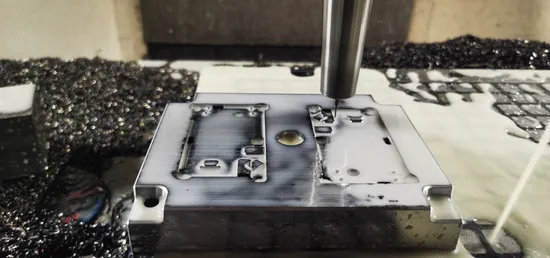

Detailed Photos

FAQ

Q1:What is your business scope?

A1: Our factory provides:

1.Design and manufacturing services for plastic injection molds, die-casting molds, and cold extrusion molds.

2.Production services for the aforementioned parts.

Q2:Can you help to develop an idea for a new product?

A2: Yes. We are always happy to cooperate with potential customers to evaluate the technical feasibility.

Q3:How to have my components quoted?

A3: Please share us your drawings with 3D format (.STEP or .IGES files) and detailed BOM sheet. We are pleased to sign the NDA with your company

Q4:How to shipment?

A4: By air or sea.From port Shanghai. Certifications

>> Ethernet network internet cable cat 6 rj45 patch cord

>> Stone CNC Cutting Router Machine for Making Statue Sculpture

>> Yp-PP-Ssms/Ssmms Automatic Melt Blown Nonwoven Fabric Machine for Disposable Protective Equipment

>> JKMF High Speed Dessert Bread Flow Packing Machine Donut Packing Machine Twist Donut Wrapping Machine

>> 5m Inflatable Teddy Bear Inflatable Giant Advertising Bear

>> Hot Melt Sealing Tape for Protective Gown

>> Wholesale 3 in 1 USB Data Cable 6A 66W Micro phone cable Micro USB Type C USB Charging Cable for iphone

>> Custom Washable Black Garment Bags for Closet Storage and Travel Folding

>> Kids Gift Headband Cartoon Animal Batteries Operated Waterproof LED Headlamp

>> double glass plastic frame casement door

>> American Nfrc High Security Modern Design Aluminum Profile Frame Thermal Break Low-E Laminated Glass Aluminium Casement Window

>> High efficiency air condition radiator copper wire separator machine

>> Non Slip Safety Stairs Stainless Steel Expanded Metal Mesh

>> Yellow Color Sf20 PVC Floats

>> qingdao humanity graphene fishing rods ultra light medium light fishing rod sleeve 8m1

>> 2024reliable Reputation Glass Storage Transportation Racks U Frame Rack Glass Rack

>> Geming RoHS Approved Timotion Table Actuator Lift Heavy Duty Lifting Column with Factory Price

>> Wholesale Popular Garment Accessories Gift Wrapping Flower Packing Home Decoration Christmas Party Deco Polyester Satin Ribbon

>> Automatic Beef Jerky Food Packing Machine

>> Factory Direct Cooling And Heating 18000BTU To 60000BTU Floor Standing Air Conditioner

>> adjustable fishing fighting belt rod fishing rod blanks 100% carbon gw or fiberglass or mixed material fishing rod

>> Soccer Nets for 5/7/11players Knotted Plastic Football Net for Gymnasiums Schools Training

>> New Classic Fashion Double Layer Shoulder Bag

>> Bohai 11.5 Cubic Screw Air Compressor for Cement Powder Tank Truck Semi-Trailer

>> Horizontal Ribbon Mixing Machine Ribbon Mixer for Powders with CE

>> Agriculture Industry Widely Use Submersible Sewage Pumps (HD1150F-1550F)

>> 75X80 Cm Dark Gray Glazed Floor Marble Look Full Body Porcelain Tiles

>> Women′s 2mm Wetsuit One-Piece Long / Bikini Style

>> Large Output 800-2000kg/H Mini Wheat Thresher Machine for Sale

>> At112 Remote Control Bird Caller TF/FM/Recording Amplifier Wireless Bluetooth Speaker