Plastic High Speed Mixer Blending Heating Cooling Mixing Machine

| US$15,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

QNH

Application

Liquid with Suspended Solids, Powder, Viscous Fluid, Liquid, Granules

Application Area

Food

Certification

ISO

Condition

New

Mixing Drum Shape

Conical

Stirring Type

Spiral

Warranty

1 year

Working

High Speed Mixer

Overall Dimensions

6265*3646*2170mm

Feeding Port

φ219mm

Motor Power

90kw

Full Volume

500L

Mixer Type

Powder Mixer

Layout Type

Horizontal

Operating type

Continuous Operating

Transport Package

Wooden Box

Specification

S304

Trademark

qianniao

Origin

Shanghai, China

Production Capacity

300sets/Year

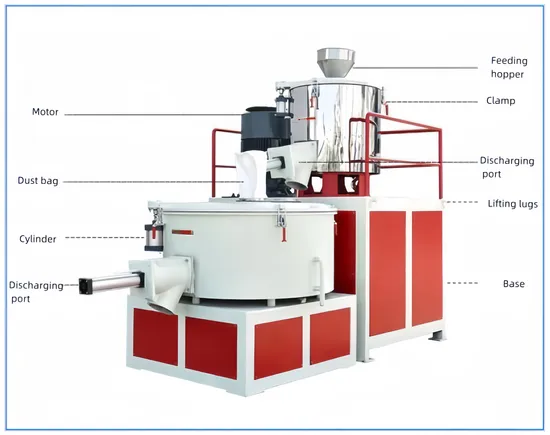

Product Description

1. Product introductionHigh-speed mixers are widely used in industries such as fine chemicals, batteries, plastics, feed, food, biotechnology, pharmaceuticals, metals, cosmetics, and construction materials, etc. By the high-speed rotation of the stirring blades in a short time, various powders can achieve an ideal mixing uniformity. Especially for shear-sensitive crystalline powders, it has better mixing results.

2. Product features

★The blades are made of thickened stainless steel castings parts, which are precisely calibrated through dynamic balancing to ensure high-speed rotation without vibration;

★Pneumatic discharge outlet with controllable discharge, saving time and labor;

★All parts in contact with materials are made of high-quality SUS 304, and are finely welded and polished smooth;

★Equipped with an integrated electrical cabinet, incorporated with timing and cooling functions, and with additional overload protection function for safe operation;

Product parameters

| Motor power (KW) | Full volume (L) | Overall dimensions (MM) | Feeding port (MM) | Processing capacity (L/H) |

| 90 | 500 | 6265*3646*2170 | φ219 | 300 |

2. Vedio instruction for operation.

3. User manual and installation instruction, layout and drawings.

4. Lable&marks for disassemble parts, wiring&cables.

Our Advantages 1.Reliable

Most popular design with years' verification.

Mature supply chain for raw materials with strict quality assurance.

International famous brands of key parts i.e. ABB invertor, Siemens electronics, Siemens motor, Mettler Toledo scale etc.

2. Economy

European technology commercialized in China.

High efficiency mixing performance.

Cost effective solutions.

3 . Professional

Over 200 mixing dosing feeding projects for bulk materials erected and running well.

Top engineers of China with over 25 years' experience of mixing dosing feeding technologies for bulk materials.

Custom proposal for each client as per specific requirements.

>> Tool Grinding Machine MR-13B Portable Idiot Drill Grinde

>> Industrial Peanut Butter Making Machine High Quality Nut Butter Maker Machine Colloid Mill Machinery Equipment Factory Sale

>> Automatic Corrugated Carton Paper Roll Shaftless Mill Roll Stand

>> Cosmetic Liquid Foundation Cream Making Machine Vacuum Mixer Homogenizer Emulsifier Tank

>> Professional Facial Magic Mirror Skin Analyzer Machine Skin Analysis

>> Uht Pasteurizer Pipeline Sterilizer Milk Sterilization Plant Stainless Steel Beverage Fruit Juice Tubular Type Sterilizing Machine

>> Precision CNC Whirling Machine for Screw Pump Components

>> Factory Precision CNC Aluminum Parts Machining CNC Turning Drone Pipe Clamp Aluminum Parts

>> Stuff Your Own Teddy Bear Stuffing Machine with Ce

>> 35GSM PP+PE Non Sterile nonwoven suit knitted cuffs ppe nonsurgical Disposable Isolation Gown

>> Mesh, Cotton Fabric Winter, Summer, Spring, Autumn Hentol Fujian, China Sport Custom Tennis Shoes

>> Timing Chain Kit for Ford Ranger 3.0L with OE GY01122016 ZZS111316 TK1346

>> Suntek Hot Sale Wholesale Customized 21 Inch 3 Fold Umbrella Printable Sublimation Blanks

>> Haichen 360ton Automatic Plastic Bottle Pet Injection Molding Machine

>> Pomegranate Extract Polyphenols 80%

>> Fully Automatic Recycled Plastic PP PE Recycling Machine Washing Line

>> 2022 New Design Tracksuit Yoga Sports Wear Suit Training Wear men Joggingsuit Jogging

>> Auto Body Parts S Class W221 Front Bumper Lower Grille Vent 2218851722

>> Synthetic Silicone Rubberhot Air Duct

>> 4yz-4SL Self-Propelled Corn Combine Harvester Farm Machine with 160HP 4rows Luxury Cabin.

>> 2021 New Crop Green Chili

>> High Power Ultrasonic Sewing Machine Rotary Welding Seamless Sewing Machine

>> Garlic Potato Harvester Tools Potato Collecting Harvester Potato Harvester Machine

>> Customizable Outdoor Wood Storage Fireplace Stove and Log Rack

>> Xiantao Xingrong Disposable Nonwoven Doctor Cap PP Cap

>> Copper Brazed Plate Heat Exchanger for Solar Water Heating System

>> Best Price Monoblock Miter Cut Granite Bridge Saw Automatic Stone Cutting Machine

>> High Precision Industrial Drill Press 20mm (Z4120)

>> Double Shaft Scrap Copper Wire Recycling Electrical Copper Cable Iron Steel Metal Cans Shredder Recycling Machine

>> AS2047 label Sound insulation Energy saving double glazed aluminium tilt and turn window