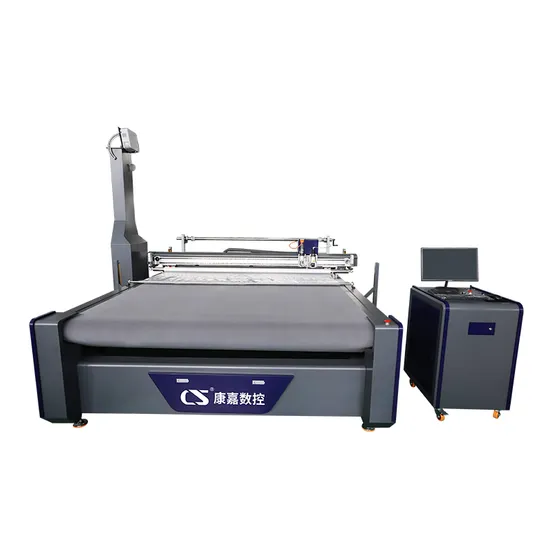

CNC Digital Oscillating Knife Fabric Cutting Machine

| US$12,500.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

PDS-SL2015

Certification

CE

Condition

New

Control

Automatic

Application

Paper, Plastic, Leather, Fabric

Power Source

Pneumatic

Layout

Vertical

Guide Rail

PMI

Control System

LED Touch Screen

Frame Structure

Integrated Framework

Name

Oscillating Knife Cutting Machine

Transport Package

Film Packaging+Wooden Case

Specification

4.3*2.27*1.75m

Trademark

Jianeng

Origin

China

HS Code

8451500000

Production Capacity

500 Sets/Years

Product Description

Product DescriptionProduct Parameters

| model | PDS-SL1615 | PDS-SL2015 | PDS-SL1825 |

| Effective cutting area | 1500*1600(L*W) | 1500*2000(L*W) | 2500*1800(L*W) |

| Operating mode | automatic | automatic | automatic |

| Voltage | 110V/220V/380V±10%, 50HZ 60HZ | 110V/220V/380V±10%, 50HZ 60HZ | 110V/220V/380V±10%, 50HZ 60HZ |

| Cutting speed | max 1400mm/s (Elite version) | max 1400mm/s (Elite version) | max 1400mm/s (Elite version) |

| Cutting thickness | ≤50mm | ≤50mm | ≤50mm |

| Power | 9KW | 9KW | 9KW |

| Cutting accuracy | ±0.1mm | ±0.1mm | ±0.1mm |

| Cutting Materials | Flexible Materials | Flexible Materials | Flexible Materials |

| Material fixation method | vacuum adsorption | vacuum adsorption | vacuum adsorption |

| Control system | LED touch screen | LED touch screen | LED touch screen |

| Transmission interface | USB /inernet port | USB /inernet port | USB /inernet port |

| Drive motor | Panasonic(Elite version) | Panasonic(Elite version) | Panasonic(Elite version) |

| Rail | PMI | PMI | PMI |

| Safety device | emergency stop button, infrared beam, anti-collision | emergency stop button, infrared beam, anti-collision | emergency stop button, infrared beam, anti-collision |

| Architecture | integrated framework | integrated framework | integrated framework |

rust-free. The tube has a built-in silencer sponge, which is cushioning and noise-reducing. Equipped with infrared induction blocking, anti-collision and emergency stop devices to ensure

safety. The cutting area has an intelligent infrared sensor stop function. If there is an obstacle or the hand reaches in during the processing, the machine will automatically pause to ensure safety; there are anti-collision functions on both sides of the beam, and the collision will stop to ensure safety; in addition, the equipment is equipped with an emergency stop. button, and continue cutting in situ after emergency stop. Detailed Photos

1. High-precision servo motor, optional Delta or Panasonic brand, multi-functional real-time automatic gain adjustment; with super strong vibration suppression function. 2. The whole machine is welded with thick-walled seamless steel structure and treated with high-temperature tempering. It is finished by CNC machining center to ensure high precision, no deformation and long service life. 3. Magnesium-aluminum alloy vacuum adsorption table, hard oxidation and other processes, durable and non-deformable, high flatness, uniform suction. Application

Vibrating knife cutting machines are widely used in clothing, bags, shoes, printing, packaging, advertising, and automotive interior mats. In the clothing, bags, and shoes industry, it is often used as a cutting machine; in the printing, packaging, and advertising industry, it is called a computer cutting machine or a sample cutting machine; in the automotive interior mat industry, it is still called a vibrating knife cutting machine. Company Profile

Quality:

Integrated welding frame body,the preferred parts work stable,long service life. Service:

Lifetime after-sales, 24-hour standby service free update software,version and other regular visits.

Secure:

Infrared induction + mechanical collision avoidance system is safer and more assured.

Feature:

Eight kinds of cutter head interchange, meet a variety of materials cutting,punching.indentation,etc., One machine multi-purpose support multi-cutter head equipment customization. Precision:

Higher cutting accuracy. The error is within 0.lmm.

Environmental protection:

Cold cutting dust-free, smoke-free,natural environmental protection does not destroy the material

Brain power:

Automatic cutting equipment, automatic plate holding software. Save materials and eliminate waste. Packaging & Shipping

FAQ Q: 1. How can I choose a suitable cutting machine? A: Please provide us some info, then we can recommend you the suitable machine:

1)What materials are going to cut?

2)What's the largest size of original materials?

3)What's the thickness of materials?

Q: 2. Can you design a machine for me depending on my requirements? A: Of course, we will discuss details with you and give you our professional suggestion for the machine ensure the machine could match all your requests with best cost performance.

Q: 3. What should I do if the machine has any problem in future? A: We supply online technical support and door to door service. Anything confuse you, just contact us.

Q: 4. What's the warranty policy? A:Standard warranty is 12 months upon delivery. Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period. Problems caused by wrong operate will also well-solved.

Q:5.What is the Price and payment terms? A:EXW,CIF,FOB we all can accept payment:TT/Paypay/LC/Western Union.etc

Q: 6.What's the package? A: Film packaging+wooden case. Fumigation-free plywood case is also available.

>> USA Approved Concession Coffee Hot Dog Food Truck with Full Kitchen Mobile Ice Cream Hot Dog Food Truck for Sale

>> Plastic Spoon Injection Molding Machine

>> Hantek Hdm3065b Benchtop Digital Multimeter 30, 000 Readings/Sec 35ppm Six-and-a-Half-Digit Reading Multimeter

>> Taijia concrete rebar locator scanner integrated rebar scanner the protective layer thickness

>> 4jb1 Diesel Long Block Bare Engine

>> High Speed Dispersion Mixer for Chemical Industry Hydraulic Lifting Dispersion Machine for Ceramic Glaze Chemical Ink Automotive Paint

>> Automatic Waste Scrap Hard Plastic LDPE HDPE PP PE Recycling Line Equipment Washing Line Price for Sale

>> Automatic High Production Weighing Fiber Jacket Filling Machine (M2-4)

>> Metal Storage Rack, Storage Shelving Rack for The Kitchen, Elegant Disign, Adorable Shape, Easily Move, Multi-Colors, Adustable

>> Soft and Cozy Children′s Bathrobe for a Relaxing SPA Day

>> Durable Ingersoll Rand RM220kw Industrial Screw Air Compressor

>> 9.25 "Nimo Knives R7 D2 Steel Satin Blade Aluminum/G10 Handle Floding Knife

>> HC-S519 Medical science pleural drainage thoracentesis drainage teaching manikin

>> Refrigerator Copper Capillary Spare Parts for Repair

>> Waste Carton Test Liner Corrugated Fluting Kraft Paper Making Machine

>> Hr Filtration 2-Stages Pusher Centrifuge Used for Sodium Chlorate

>> Industrialgrade 250 1200 Jaw Crusher Rock Gold Processing Plant for Quarry

>> Electric Power Tools Electronic Cutter Wired Scissors for Household Crafts

>> High Speed Original Photo ID Card Machine Hiti CS200e Thermal Smart Card Printer

>> Habilead Brand P205/70r15 P215/70r15 P225/70r15 P205/75r15 All Season Car Tyres

>> High Quality High Precision European Standard Advanced 3015/4020/6020/6025 Fiber Laser Cutter

>> Ganoderma Lucidum Reishi Mushroom Extract Supplement Anti Oxidative

>> Marine Port Use Semi Automatic/ Manual Container Lifting Beam Container Hanging Beam Lifting Frame for 32t/36t 20/ 40feet Container Lifting Spreader

>> Rugged Waterproof Industrial Touch Screen Panel PC

>> Gypsum Brick/Block Making Machine Hollow Block Pallet Plant Gypsum Powder Making Machine

>> High Precision Automatic Alloy Wheel Repair Machine Br-28

>> High Peeling Rate Peanut Peeling Machine Peanut Sheller Machine

>> Good Quality 50W 60W 80W 100W 4060 CNC CO2 Laser Engraving Machine

>> Satin Wig Bags with Drawstring, Hair Extension Packaging Bags Travel Bag for Hair Tools Home Travel, Storage Bags for Salon Use

>> Automatic Dry Wet Groundnut Peanut Picking Picker Machine Peanut Harvester Picking Machine Peanut Harvesting Machine Best Price for Sale