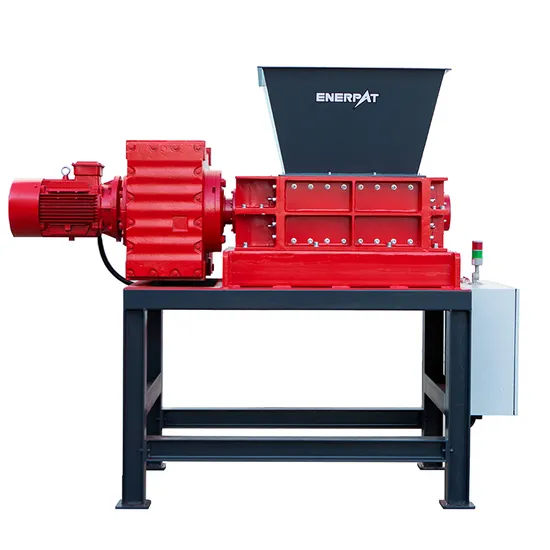

Aluminum Waste Recycling Machine - Twin Shafts Shredder with CE Certification

| US$8,000.00-200,000.00 | 1 Set (MOQ) |

Basic Info.

Material Processed

Technology Support According to Your Raw Material

Plastic Type

Design According to Your Material

Screw

Single,Double,Four

Automation

Automatic or Semi Automatic

Computerized

Customized

Certification

ISO9001:2008, CE

Electrical Systems

Siemens/Schn Eider PLC Electrical Systems

Feature

Low Speed,Large Torque,Low Energy Consumption

Motor

Single Motor, Dual Motor

OEM ODM

Support

Package

with Film and Wood Package

Porting

Shanghai or Customized

Factory

Welcome to Visit The Factory

Quotation

Online Discussion

Transport Package

Plastic Film, Steel Frames, and Wooden Boxes

Trademark

Enerpat

Origin

China

HS Code

8477800000

Production Capacity

20PCS/Month

Product Description

Product DescriptionEnerpat offers a wide range of recycling engineering- and scrap processing-related products and services. Its products can be broadly divided into the following categories: Car Recycling Plant, Tyre Recycling Plant, E-Waste Recycling Plant, Municipal waste recycling plant. Waste Shredders, Waste Balers, And Waste Machines. And transportation and logistics-related products

Contact us to provide you with a solution that suits you

Details

Detachable box

1. The shredding chamber body can be deconstructed from each end of the coupling. The main shaft can be detached as a whole by removing the mounting plate at each end of the bearing.

2. Once the main shaft is dismantled,the cutter body and bearings can be kept and inspected,and if need be,then it can be replaced as well.

3. Regarding the processing of the shredding chamber, care should be taken to position the main shaft and bearing at central position during installation to ensure that the structure remains intact and lasts longer.

Heavy-load planetary reducer

1. It has a box of rigid casting reducer consisting of gussets.

2. The sturdy finishing gear is composed of high-quality steel alloy,and the surface is processed through carburizing and quenching methods.

3. Then,the structure is finely processed by means of gear grinding.This through process ensures many operational benefits,such as stable transmission power, low noise and greater carrying capacity.

Detachable cutter

1. Detachable blade design greatly reduces blade replacement time

2. A complete crushing blade comprises of three parts.

3. It is quite easy to replace a worn blade: simply loosen and tighten the bolt.

Electric system

1. The electric cabinet is equipped with a Siemens/Schn eider PLC.

2. The electric cabinet boasts a touch screen with a high capability of promoting human-machine interaction.

3. Siemens/Schn eider electrical components are adopted.

Sealing system

1. The bearing has a quadruple sealing protection design which makes it dust proof and waterproof, effectively prolonging the service life of the bearing.

2. Therefore,it can work excellently in an outdoor, highly dusty environment.

Auxiliary system

1. A pressing device is optional.It can help to crush materials rapidly.

2. A rotating screen is optional,and it guarantees dimensional uniformity of crushed products.

Splined main shaft

1. The moving blade base and the main shaft align in spline transmission.

2. The design consist of a large surface junction without stress concentration.

3.The spiral configuration of the moving blade base can enhance its crushing efficiency and reduce energy consumption.

4. The moving blade base has been tested by using 100% ultrasonic and non-destructive inspection to maximize the cutter's crushing capacity. dimensional uniformity of crushed products.

Heavy-load self-aligning bearing

1. We install heavy-load self-aligning bearings on two main shafts.

2. When a blade is impacted by a heavy load,the heavy-load self-aligning bearing produces an immense mechanical action that relieves the impact force.

3. We choose the world's leading bearings.of brands such as F AG and S KF as a standard configuration for all ENERPAT shredders.

Applications

Crushing Effect

Technical Data Sheet

| Model | MSB-E300 | MSB-E600 | MSB-E800 | MSB-E1000 | MSB-E1200 |

| Motor Power (KW) | 7.5/11 | 11/15 | 15/30/60 | 37 | 44/90/150 |

| Blade Diameter (mm) | ∅170-300 | ∅270-300 | ∅270-450 | ∅270-450 | ∅320-520 |

| Shaft Speed (RPM) | 13-18.5 | 9-32 | 10-32 | 10-32 | 7.5-32 |

| Shredding Chamber Length (mm) | 300 | 600 | 800 | 1000 | 1200 |

| Blade Material | Germany | Germany | Germany | Germany | Germany |

| Blade Thickness (mm) | 20 | 20/30 | 20/30 | 30/40 | 30/40 |

| Machine Size (mm) | 1500×1300×1850 | 2500×1300×1850 | 2700×1300×1850 | 3300x1900x2200 | 3600×2000×2200 |

| Machine Weight (kgs) | 1000 | 1500 | 2300 | 5200 | 6400 |

| Model | MSB-E1600 | MSB-E1800 | MSB-E2000 | MSB-E2200 |

| Motor Power (KW) | 90 | 180/220 | 180/220 | 220 |

| Blade Diameter (mm) | ∅450-800 | ∅450-800 | ∅450-800 | ∅450-800 |

| Shaft Speed (RPM) | 5.5-14.5 | 5.5-14.5 | 5.5-14.5 | 5.5-14.5 |

| Shredding Chamber Length (mm) | 1600 | 1800 | 2000 | 2200 |

| Blade Material | Germany | Germany | Germany | Germany |

| Blade Thickness (mm) | 50/75/100 | 50/75/100 | 50/75/100 | 50/75/100 |

| Machine Size (mm) | 5500×2200×2600 | 7000×3100×4000 | 7500×3500×4400 | 8000×4000×5000 |

| Machine Weight (kgs) | 30000 | 34000 | 40000 | 45000 |

Successful Cases

About Us

>> Good Sealing Banbury Mixer / Rubber Kneader / Internal Mixer with Best Rotors

>> Ex-Factory Price of Pdj Mode Balance Crane

>> Juxing Ss3200 200V3a Ifsm150A Vf0.95A Surface Mount Schottky Rectifiers Diode with SMC

>> Custom Red Rubber Compound for O-Rings, 25-100 Shore a Hardness

>> Waste Plastic Recycle PE Film Granulator Two Stage PP PE Bags Pellets Making Machine

>> China Zhongshan Manufacturer Wholesale Custom Cartoon Soft Hard Enamel Metal Pin Badges Emblem High Quality Glitter Anime Enamel Lapel Pin Badge

>> Ultrasonic Welding System Core Parts Digital Generator for Welding Machine

>> Indoor Outdoor 9W LED Wall Lamp Aluminum Triangle Surface Wall Mouted Light (WH-RC-21)

>> Mini Cigar acrylic and wood packing case cigar packing box

>> Professional Surgical Titanium Products Factory Manufacturer Medical Titanium Bars for Sale

>> Modern Design Melamine Series Sliding Door (Br-Sm002)

>> Stainless Steel Bench Scale 300kg*1g/2g/5g

>> Easy to Operate Color Difference Portable Colorimeter

>> DC 12V 24V AC 110V 230V AC Customize Strong Electric Actuator Linear Electromagnet Electromagnetic Pull Type

>> Hydraulic Jack 20ton Factory Price OEM Car Repair Lifting Tool

>> Custom Pink Rabbit with Blanket Soft Plush Toy Stuffed Animal

>> Byloo China customized casting fishing anti-weed weedless metal brass fishing spoon lure 1/8oz, 1/4oz, 1/2oz, 3/4oz

>> Neodymium Block Magnet Permanent Strong Nickel Plating Magnet

>> 1600mm Feeding Width, Chain Plate Feeder Structure Diesel Engine Log Shredder

>> Chinese Wenovus Wngs-120 Multi-Functional Fast-Cutting Agricultural Machinery Gasoline Powered Reaper Farm Machine Grain Reaper Paddy Reaper

>> Trolley BBQ Smoker Grill (TM-C002)

>> China Factory Price Manufacturer CNC Metal Spinning Lathe Machine CNG Seamless Cylinder Gas Cylinder Neck Threaded Screw Machine

>> Soft Uniform Shirt Fabrictc65/35 45X45 133X72 110GSM Poplin Continuous Dyeing

>> Xg-75kw New Generation Wire Saw Machine for Granite and Marble Quarry Cutting

>> Full Spectrum 600W 1000W Indoor Light Strip LED Grow Light for Plants

>> Uncoated Bond Paper/White CAD Plotter Paper

>> 3A Donjoy SS316L Sanitary Twin Screw Gear Pump with Safety Valve

>> Hydraulic Leather Production Swing Arm Cutting Machine

>> 7-400 Heavy Duty Double Powder Fresh Noodle Machine Noodle Making Machine Pasta Making Machine

>> Wholesale 5HP-7HP Mini Agricultural Farming Machinery Equipment Gasoline Power Engine Plough Walking Cultivator