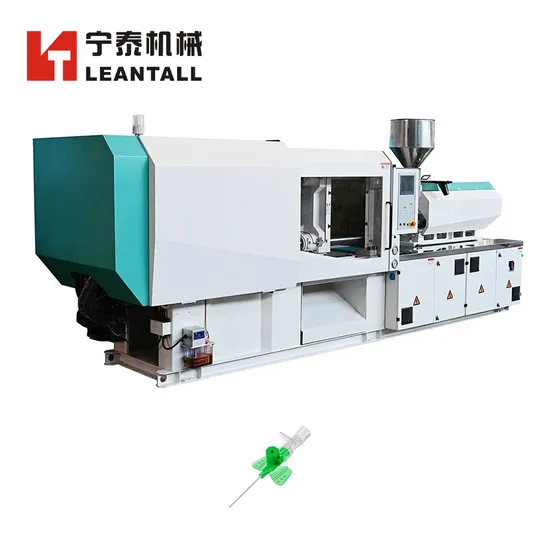

Best Selling Products Injection Molding Machine Manufacturer Safety Helmet Industrial Camera Nt500

Basic Info.

Model NO.

NT500

Type

Preform Injection

Structure

Horizontal

Plastic Type

Thermoplastic

Plasticizing Way

Plunger Type

Clamping Way

Hydraulic

Automation

Automatic

Computerized

Computerized

Certification

ISO9001:2008

Marketing Type

Hot Product

Core Component

Motor, PLC

Material

Stainless Steel

Applicable Industrial

Manufacturing Plant

Voltage

380V/50Hz 3p+N+E(Alterable)

Function

Plastic Parts Production

Mold

Can Be Customizable

Clamp Force

5000kN

Space Between Tie Bars

830*780

Transport Package

at Seller′s Option

Specification

7.9m*1.95m*2.4m

Trademark

Leantall

Origin

China

Production Capacity

20sets/Month

Packaging & Delivery

Package Size

790.00cm * 195.00cm * 240.00cm

Package Gross Weight

16000.000kg

Product Description

Product Parameters

| Part | Name | Unit | NT500 | ||

| Injection Unit | SCREW DIAMETER | mm | 70 | 75 | 80 |

| SCREW L/D RATIO | L/D | 21.4 | 20 | 19 | |

| INJECTION STROKE | mm | 390 | 390 | 390 | |

| NJECTION SPEED | Mm/sec | 103 | 103 | 103 | |

| SHOT VOLUME(THEORETICAL) | CM3 | 1501 | 1723 | 1960 | |

| INJECTION WEIGHT(PS) | g | 1366 | 1568 | 1784 | |

| INJECTION PRESSURE | Mpa | 194 | 169 | 148 | |

| INJECTION RATE | cm³/sec | 396 | 455 | 517 | |

| PLASTICZIATION CAPACITY(PS) | g/sec | 63 | 78 | 93 | |

| SCREW SPEED | rpm | 160 | |||

| Clamping Unit | CLAMP FORCE | Kn | 5000 | ||

| OPEN STROKE | mm | 800 | |||

| SPACE BETWEEN TIE BARS | mm×mm | 830X780 | |||

| MAX.MOULD HEIGHT | mm | 850 | |||

| MIN.MOULD HEIGHT | mm | 280 | |||

| EJECTOR STROKE | mm | 200 | |||

| EJECTOR FORCE | Kn | 111 | |||

| EJECTOR NUMBER | N | 13 | |||

| Others | MAX.PUMP PRESSURE | Mpa | 16 | ||

| SEVRO DRIVE POWER | Kw | 50 | |||

| HEATING POWER | Kw | 29.5 | |||

| MACHINE DIMENSION(L*W*H) | m×m×m | 7.9*1.95*2.4 | |||

| MACHINE WEIGHT(ESTIMATE) | T | 16 | |||

Product Description

Packaging & Shipping

Company Profile

Our Advantages

Q: Are you manufacturer or trading company? A: We are manufacturer with decades experiences,located in Zhejiang province. Q: What is the product range? A: Focus on the manufacture and development of plastic injection molding machines and its auxiliary equipment such as cooling tower, chiller, etc. Q: Where is your main selling market? A: We have business domestic,USA,Russia,Indonesia,Egypt,Turkey ,Uzbekistan, Pakistan,etc. Q: Will you offer field installation and operator training at the buyer's factory? A: Yes,we will arrange our skilled engineers for filed installation and training. Q: What is the delivery time(equipment production time)? A: It will be ready around 50 days after getting mutual confirmation about the order details and prepayment. Q: Do you also have source for molds and spare parts? A: Yes,we can offer with the competitive quality and reasonable price. Customized as required. Q: What is the standard of package? A: Wooden case packing for the auxiliary equipment, bare packing for the plastic injection molding machine. Full container shipment is highly suggest.

>> Factory Direct Sales 3ply Face Mask for Daily Protection/Prevention of Bacterial Infection

>> Evga Supernova 1600 G+ 80+ Gold 1600W Fully Modular Includes Free Power on Self Tester, Power Supply

>> Home Waterproof Security Camera CCTV Complete Kit Systems

>> Good Fuel Pump for Completely Japanese Car List Ep500

>> Launder-Ometer /Washing Color Fastness Tester & Textile Color Fastness Test Machine

>> OEM Universal 1lb Tank Bottles Propane Gas Fill Refill Adapter China Factory

>> 1000W 1500W 2000W Handheld 3 in 1 Laser Machine with Touch Screen

>> Precision Vt Type 0.75ton Manual Lever Chain Hoist

>> Optimized H Type Broiler Cage Fully Automatic

>> Champagne color aluminum windows double glazed windows

>> Office Supply A4 Waterproof Envelop PP Custom File Folder with Multi Colors

>> Unlocked Huawei E5577CS-321 4G LTE Cat4 1500mAh Mobile Hotspot Wireless WiFi Router Pocket 2PCS Antenna

>> Self Load Concrete Drum Mixer Truck 5.5 Cubic Meters Self Loading Concrete Mixer Truck

>> 3 Years Long Shelf-Life Canned Food Braised Flavor Canned Stewed Beef

>> Portable Digital Hanging Crane Scale Alloy Shell Scale Ocs D2

>> 877max Garage Door Keypad Control with Fingerprint Function 893max Wireless Fingerprint

>> Hobby 1kw 1500W 2000W High Speed Metal Copper Steel Cutter Laser Cutting Machine Hot Sale

>> Soldering Electronic Video Microscopes Continuous Amplification Magnifier Digital for Phone PCB Repair

>> 5-8cm Shandong Small Packing Big Fresh Onion

>> Wholesale Custom Elastic Waistband Logo Jacquard Elastic Tape for Underwear

>> China Manufacturers 4 Hole Inside Corner Brackets for 3060c-8A Profile Aluminum Extrusion

>> Top Quality Ca6140 Ca6240 Manual Turning Lathe Price Chinese Metal Lathe

>> 216NG62A HESG441634R1/K HESG216876 ABB module inventory spot sale

>> Mini Upright Stage Effect CO2 Jet Machine with Angle Adjustable

>> Iron Nail Packaging Prices Refill Machines And Pack Spices Old Pouch Water Commodity Packing Machine

>> Hot Automatic banding machine small vegetable strapping machine without glue hot melt opp belt baler baler supermarket bundle

>> Rubber Floor Tile Making Machine with 100% Factory Price

>> New Style Medical Uniform Scrub Uniform Short Sleeve Tunic Coats with Custom Logo Hospital Uniform Doctor Dress

>> Backpack Preschool Boys Girls Elementary Bookbag Kids Lightweight Casual School Bag

>> Hua Hong Hpm-315 Plastic Recycling Use a Wide Range