High Speed High Torque Drilling and Tapping Center Machine Size T8

| US$10,000.00-100,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

T8

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Point to Point Control

Control Method

Open-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE, ISO 9001

Condition

New

X×y Travel

850×550

Table Size

1000×550

Spindle Rpm

10000/12000

Capacity of Atc

24

Transport Package

Seaworthy

Specification

15CBM

Trademark

Zhongnan

Origin

China

HS Code

8457101000

Production Capacity

3000sets/Year

Packaging & Delivery

Package Size

2250.00cm * 2200.00cm * 2100.00cm

Package Gross Weight

1000.000kg

Product Description

BRIEF INTRODUCTIONHigh Speed High Torque Drilling and Tapping Center Machine T6(travel 600×400mm)

Zhongnan's T series tapping center is a new generation machine tool with high-precision, high-speed, high-efficiency. With once clamping, it can do various machining of parts such as milling, drilling, reaming and tapping automatically and continuously. The machining of various planes, holes and complex contour surfaces suitable for medium batch production, especially small and medium-sized box parts with many holes, more convenient, saves clamping time, shortens the production cycle, and improves the machining accuracy. It is widely used in industries of defense industry, tractors, light industry, automobile manufacturing, textile machinery, molds and etc..

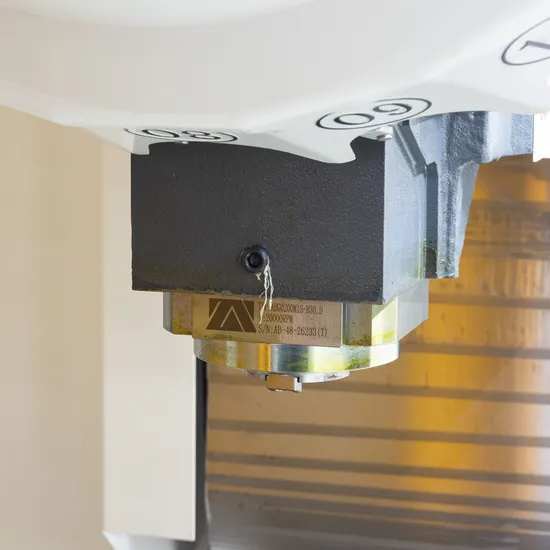

Features of Zhongnan's CNC drilling and tapping center: The high-speed spindle is used to realize high-speed and high-precision machining. Equipped with imported 21T magazine, tool change is fast and stable. The machine has a large inclined angle design for chip removal, quickly flushes away iron chips, and speeds up the return of cutting fluid Powerful mechatronics application technology improves the response speed of transmission, eliminates no action during processing, reduces cutting time, and significantly improves production efficiency High rigidity FC300 casting. High speed spindle Max RPM 20000

Parameters of Zhongnan's CNC tapping center T6

| Name | Unit | Model T6 |

| Worktable dimension(L×W) | mm | 700×400 |

| Max load of worktable | kg | 250 |

| T groove (quantity×width×distance) | mm | 3×14×125 |

| X axis travel | mm | 600 |

| Y axis travel | mm | 400 |

| Z axis travel | mm | 320 |

| Spindle end to worktable | mm | 130-450 |

| Spindle center to column | mm | 410 |

| Spindle type | BT30 | |

| Speed of spindle | RPM | 20000 |

| Drive of spindle | Direct drive | |

| Power of spindle | Kw | 3.7/5.5 |

| Torque of motor(X/Y/Z) | N.m | 8/8/12 |

| CNC system | Fanuc 0i-MF/MITSUBISHI M80/SIEMENS | |

| Rapid feed of X/Y/Z | mm/min | 48/48/48 |

| Capacity of magazine(ATC) | pieces | 16/21T |

| Positioning accuracy | mm | 0.008 |

| Repositioning accuracy | mm | 0.005 |

| Air supply | Kg/cm2 | 6 |

| Weight of machine | kg | 3500 |

| Dimension(L×W×H) | mm | 1900×2340×2450 |

Features:

High speed and high torque spindle with fast response speed, adopts ceramic ball bearings, which can substantially expend the spindle's using time.

Imported 21T ATC with swift tool change speed. High rigidty machine body with powerful drilling capacity.

Standard Configurations

| No. | Name | Quantity | Remark |

| 1 | Fanuc 0i MF | 1 | |

| 2 | Remote | 1 | |

| 3 | ATC | 1 | 21 pieces |

| 4 | Automatic lubrication | 1 | |

| 5 | Spindle blowing system | 1 | |

| 6 | Air curtain protection | 1 | |

| 7 | Standard tooling | 1 set | |

| 8 | Cooling system with tank and double pumps | 1 | |

| 9 | LED working lamp | 1 | |

| 10 | 3-color working lamp | ||

| 11 | Flushing system | 1 | |

| 12 | Cleaning water gun and air gun |

Company Profile

Nantong Zhongnan Intelligent Technology owns Zhongnan CNC technology, Zhongnan Intelligent, Xinsheng CNC technology and other subsidiaries such as foundry factory. Since its establishment in 2000, Zhongnan started with producing surface grinding machines, and gradually developed into high-end CNC machining center and manufacturing with production lines of CNC vertical machining center, high-precision gantry machining center, horizontal machining center, CNC vertical and horizontal milling machines, Zhongnan is one of the reputed manufacturers covers full production lines in the metal cutting machines industry in China. The products of the group company are widely used in defence industry, aerospace, automobile, green energy, mold and other fields of manufacturing.

Zhongnan Intelligent Technology has a production park covers 100,000 square meters. There are more than 380 employees, 30 senior engineers, and 20 R&D engineers. Production capacity covers the entire production chain of casting manufacturing, machining, painting, assembly, commissioning, inspection, etc.

100,000 square meters factory.

Factory Workshop Show

Metal working workshop 1 Metal working workshop 1 Painting workshop

Assembly workshop 1 Assembly workshop 2 Machines ready in stock

Sheet metal workship 1 Sheet metal workship 1 Foundry plant

>> Durable Machines Hydraulic Shearing Machine, Plate Cutter with High Quality

>> Durable Stainless Steel Black Galvanized Crane Wire Rope Brake Aircraft Deck Railing Cable for Heavy Lifting

>> Double Sided Grocery Store Display Racks Shelf

>> Windproof Dust suppression Net Perforated Metal Mesh Highway Guard and Noise Barrier Network

>> Non-Sparking Socket, Impact, Be-Cu, Atex, 1-1/2" Drive, 85mm

>> Block Easy to Operate Concrete Stacker Cuber Construction Machine Hot Sale System

>> Custom Plastic Pre Roll Tube for King Size Cones

>> High Quality Fresh Onion Red Onion Natural Cheap Price 5-8cm

>> Powder coating Small Hole Galvanized/Aluminum Expanded Metal Mesh Decorative Net

>> 1: 64 Engineering Vehicle Concrete Mixer Truck Mini RC Toy Car

>> Paper Machine, Kraft Paper, Paper Machine Manufacturer, Factory Price, Small Machine

>> Peanut peeling machine Small household peanut peeling machine peanut shelling machine

>> DDP/DDU China Fast Railway Shipping to Germany Europe Kazakhstan, Kyrgyzstan

>> Made in China Agricultural Adjustable Cow Grass Machine Chaff Cutter Machine Grinding Machine Crushing Machine Chaff Cutter

>> Factory Price Cam Roller Type Backstop Clutches One Way Bearings Bseu40-40

>> New 14 Piece Christmas Silicone Mold, Home Baking Chocolate Candy Mold, Christmas Gift Mold

>> High Quality Ability Factory Supply Sheet Metal Stamping Part

>> Building Material Cast Clear Acrylic Sheet PMMA for Signs

>> aluminum expanded mesh exterior decorative building facades

>> Customized Farming Rotary Tiller Accessories

>> OEM High Strength Helical Coil Compression Steel Springs for Electrical Equipment

>> Wenzhou High Quality Sanitary Negative Pressure Pump

>> Pet Bottle Embryo Injection Molding Machine Haitian Ma250 Tons Plastic Molding Machinery Used Injection Molding Machine

>> Chinese new model stainless steel fresh banana peeling machine

>> Rubber Banbury Mixer Dosing System Automatic Weighing Machine

>> 2023 latest iphone 14 pro max high quality

>> Earrow Outboard Motor Factory Best Sales High Quality 15HP 2-Stroke Enduro E15DMHL for Fishman

>> White flower pattern perforated metal mesh ceiling mesh

>> Wire Stripper Quick Wire Stripping Pliers Five in One Wire Stripping Pliers Copper Wire Stripper Wire Stripper Machine

>> Premium USB Type C Ep-Dg970bbe Data Sync and Charging Cable for Sam Sung Gal Xy S10 S20 Plus A7 A8