High-Quality Rice Vermicelli Machine with Stainless Steel and Automatic Control

| US$100,000.00-1,000,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

KR6-16

Application

Noodle, Rice Noodle

Certification

ISO, CE

Material

Stainless Steel

Lifespan

at Least 20 Years

Control System

Automatic Control Systems

Degree of Digitization

Automatic Data Storage

Commissioning Service

in-Home Service by Our Own Staff

Degree of Automation

Full Automatic

Packaging Type

Full Container Load

Transport Package

Suitable for Sea Freight

Specification

Customized

Trademark

KENNYWAY

Origin

Guangzhou, China

HS Code

8438100000

Production Capacity

16t/8h

Product Description

About KennywayennywayKennyway proudly unveils a new logo for its international business ventures in celebration of its grand 30th anniversary.

KR6 Fresh Rice Noodles Production Line FROM KENNYWAY

100% Authentic On-Site Photography

Fresh rice noodles are primarily round noodles with a one-day shelf life, perfect for supplying to select schools, canteens, breakfast shops, and other catering businesses within a specific delivery radius. The production line boasts high production output paired with exceptional automation and seamless continuity. These rice noodles offer an outstanding texture, maintaining their elasticity and quality even after extended storage periods.

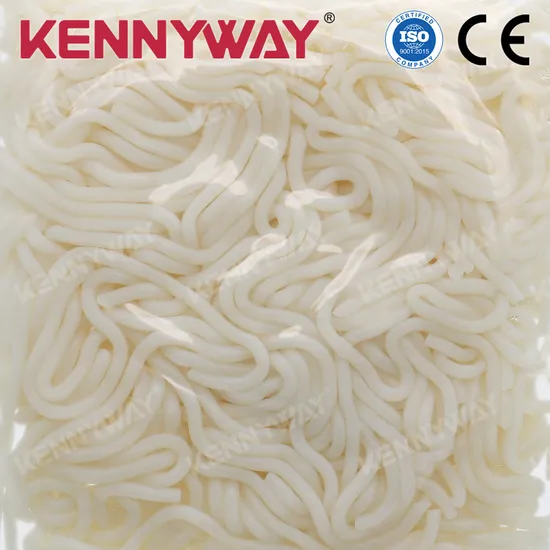

The exquisitely crafted rice noodles produced by theKR6 production line are illustrated in the subsequent image:

Outlined below is the general process flow of the KR6 line. For inquiries on the detailed process flow, please reach out to us: Rice→Elevating & Conveying→Rice Ordering Feeding→Rice Soaking & Washing→Sand Separating→Dehydrating→Grinding→Filter Press Dehydrating→Dough Breaking→Pellet Extruding→Pellet Steaming→Stick Extruding→Vermicelli Extruding→Boiling→Water Cooling→Cutting→Final Product

Presented below are the KR6 line parameters with varying capacities for your consideration:

| Type | Capacity (T/8H) | Total Power (KW) | Production Area (square meter) | Minimum Length of Workshop (m) | Steam Consumption (Kg/H) |

| KR6-16 | 16 | ~135 | ~600 | ~70 | ~1500 |

| KR6-24 | 24 | ~168 | ~720 | ~90 | ~2000 |

Kennyway provides bespoke service, ensuring each piece of machinery is meticulously crafted to align with the customer's precise requirements, guaranteeing the provision of the optimal equipment for their unique production needs.

*Both fully automatic and semi-automatic production lines are available.

*We offer automated options that deliver superior control, monitoring, and data storage solutions for your operations.

Our most advanced integrated process solutions deliver a full-service experience from raw rice to finished product. We offer comprehensive solutions covering grinding, mixing, friction-cooked extruding, aging, pressing, steaming, cutting, forming, cooling, and packaging.

Experience the pinnacle of rice noodle production with our cutting-edge machinery. Featuring the latest technology, our equipment ensures exceptional efficiency, reliability, and unparalleled quality. With 30 years of industry expertise, we deliver bespoke solutions tailored to your specific requirements. Benefit from 24/7 online technical support and access to our seasoned engineers for flawless overseas installation and commissioning. Enhance your production capabilities and maintain a competitive advantage in the market with our innovative and user-friendly rice noodle production line.

Listed below are the current production lines available from Kennyway, with asterisks indicating hot sellers.

| Production line | |||||

| rice based | wheat based (non-fried) | starch based | |||

| KR1* | Instant Flat Rice Noodles Production Line | KW2* | Twin-Steaming Noodles Production Line/Quick cooking noodles production line | KS1* | Instant Starch Vermicelli Production Line |

| KR2* | Instant Rice Vermicelli Production Line | KW3 | Wavy Type Noodles Production Line | KS2 | Boiled Starch Vermicelli Production Line |

| KR3 | Wavy Rice Noodles Production Line | KW6 | Micro-Puffed Instant Noodles Production Line | KS3 | Steamed Starch Vermicelli Production Line |

| KR4 | Rice Stick Production Line | KW7 | Non-fried instant Noodles Production Line | ||

| KR5 | Friction-cooked Instant Rice Noodles Production Line | KW8* | Semi-Puffed Snack Production Line | ||

| KR6 | Fresh Rice Noodles Production Line | ||||

| KR7* | Steziliged Fresh Rice Noodles Production Line | ||||

| KR8* | Straight Rice Noodles Production Line | ||||

About Us

Established in 1994, Guangzhou Kennyway Food Processing Machinery Co., Ltd. has been exporting since 1996. Kennyway has grown into a globally respected name in food machinery manufacturing, boasting three decades of steadfast commitment to the research and production of food machinery using rice, wheat flour, or starch as primary materials.

We offer tailored solutions for various customer needs, customizing our equipment to produce a wide array of food categories. Whether utilizing rice, wheat flour, or starch, our machinery meets an extensive range of production demands. This adaptability allows our customers to respond swiftly to shifting market trends, providing a competitive advantage.

We proudly serve a diverse clientele worldwide, not only in China but across numerous countries and regions, including Vietnam, Thailand, Myanmar, Czech Republic, France, the Philippines, Malaysia, Indonesia, Sri Lanka, Canada, the United States, and South Korea. Our clientele consists of prominent global food enterprises, and our enduring partnerships enable us to deliver highly-customized food machinery solutions.

Experience the heart of innovation with us as we lead the Factory Production, ensuring top-tier precision and performance in every machine we craft.

Join us in the Office, where strategic visions come to life and cutting-edge solutions are tailored to meet your every need.

Encounter our dynamic presence at Exhibitions, where we unveil the future of food processing technology through interactive displays and expert insights.

>> 1800t Solid Tyre Vulcanizing Press Machine Tyre Molding Press Machine

>> Wear-Resistant High Elastic Polyurethane Sun Wheel Polyurethane Light Pressure Wheel

>> Competitive Price Poly Core Spun Yarn 100% Polyester Yarn High Tenacity Sewing Thread 40s/2 20s/2 20s/3

>> High Definition Multi Function Wall Stand LCD Digital Screen Interactive Smart Display Meeting Room All in One Touch Whiteboard

>> Intelligent electric lift gate manual-automatic mode switching foot kick sensor for Mazda CX-5

>> China Factory Small Farm Mini Power Cultivator Tiller and Cultivator Plough Tiller

>> High Quality Snack Foods Dubai Wholesale Canned Roasted & Salted Peanut

>> Online Shopping Flex Metallic Tube Forming Machine

>> Premium Grade 150d/2 100% Viscose Rayon Embroidery Thread Collection

>> HC-S412 Dental lesion series model/Dental Diseases Model, Lesion Teeth model

>> Control System As380 Integrated Controller for Passenger Elevator

>> New Style Automatic Multi Rip Blade Saw Cutting Machine for Spc Flooring Producing

>> Hot Sale Low Price Carbon Raiser Additive Carburant Calcined Anthracite Coal

>> Auto parts radiator cooling electric fan cover 12v 16711-37160 For Prius ZVW50 2015-

>> 62cc Shiwn Walking Tractor Agricultural Mini Gas Garden Power Tiller

>> High Quality Low Price Rastra De Discos Heavy Duty Disc Harrow for Farm

>> Large Capacity Low Speed Laboratory Centrifuge

>> Automatic PP Block Bottom Valve Bag Making Machine Bag Machine for PP Non-Woven Valve Bag

>> Single Driver Electric Cargo Tricycle with One Child

>> Hot Dipped Galvanised Cattle Squeeze Chute

>> Blue Flexible Light 2 Inch Agricultural Irrigation Water Discharge PVC Layflat Hose

>> High Output Investment Fully Automatic Clay Brick Factory Production Line Equipment

>> High Capacity Fiber Opening Machine for Siliconed Polyester Home Products

>> Freshly fried melon seeds five spice original flavor new bulk sunflower seeds

>> Automatic Mobile Lifter Scaffolding Hydraulic Scissor Lift Tables Platform for Aerial Work

>> China Alva Double Shaft Car Body Shredder/Mixed Scrap Metals Shredder

>> Electric Automatic Sieve Shaker Vibrating Sieve Machine

>> High Quality Wire Guide Roll for Tissue Paper Machine

>> High Performance Bed Type Milling & Drilling Machine 16mm (ZX7016)

>> Lapel Lavalier USB Clip Microphone Cable