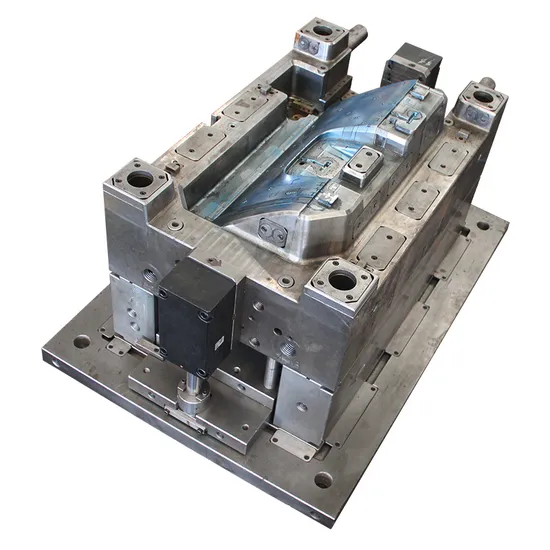

Professional Mold Maker Auto Parts Mould Automotive Panel Door Front Bumper Plastic Injection Mold

| US$3,000.00-5,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

HPD241210L042

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Plastic Material

ABS

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Electronic, Home Use

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Certification

ISO

Standard

ISO9001

Customized

Customized

After-sales Service

Available

Design Time

Within 3 Days

Runner System

Hot Runner

Color

Customized

Mold Standard

Misumi

Transport Package

Customer Reqirement

Specification

HPD241210L042

Trademark

Hiparter

Origin

Qingdao, China

HS Code

8480719090

Production Capacity

30 Sets/Month

Product Description

Product Description

Located in Qingdao, Hiparter has more than 20 years experience in designing and manufacturing Automotive Plastic Injection Mold,and we have a variety of mold manufacturing process capabilities.With this advantage, we have produced almost all Automotive Plastic Injection Mold to serve various enterprises. At the same time, we are also proficient in the development and manufacturing of injection molds for home appliances, even casting mold. Here you can experience a one-station mold service to meet your various needs.

Focus on "precise & long lifetime mold innovation and manufacturing"

We have manufacture all types of automotive cars components, it not only includes injection mold, also covers the stamping mold.

Appliaction:

·Central console bracket ·Console carrier foaming

·Front longitudinal beam ·A pillar

·Rear floor ·Bumber

·Front end module ·Graining bracket in the trunk

·Front engine cabin floor

·shock absorber tower

| Mould name: | Automotive Plastic Injection Mold |

| Mould core material: | S45C, S136, S136H, S50C, P20, 718H, 738H, NAK80 |

| Runner: | Cold runner/Hot runner |

| Hardness of steel: | HRC38~42/HRC34~6/HRC48~52 |

| Mould cavity | Single cavity |

| Mould standard: | MISUMI |

| Mould installation: | Manual |

| Design soft: | UG |

| Molding surface treatment: | Polishing,Smooth, Glossy, Textured, Matte |

| Mould Life: | 100 thousand~300 thousand times |

| Plastic product material: | POM, ASA, PP, ABS, PC, ABS+PC, PA, HIPS, PVC, PE, PS, Acrylic, etc. |

| Production process: | Injection molding |

| Mold or product size: | 1) According to customers' drawings |

| 2) According to customers' samples | |

| Warranty Period: | 1 year or 100 thousand shots(in this period, if the mold have any problem, we will offer the parts or service by free, but it does't include the problems caused by wrong operation) |

| Mould precision: | +/-0.01mm |

| Ejection system: | Motor/hydraulic cylinder/stripping plate/angle pin, etc.... |

| Cooling system: | Water cooling or Beryllium bronze cooling, etc. |

| Quality system: | ISO9001 |

Company Profile

Located in Qingdao China, Hiparter has more than 20 years experience in designing and manufacturing Plastic Injection molds,covering an area of 10,000 square meters. As a world-class company in mold making, we can provide on-stop solution for your requirements.Hiparter has passed ISO9001 quality management system certification. We can gurantee the high-precision of our mold because we have mastered the world's most advanced equipment.We have developed a full-range universal injection Mold supply, including the following areas:Aerospace,Telecommunications,Constructions,Medical etc....

1. Experienced design engineer:

Ensure the mold structure is reasonable. Guarantee success rate of first test, reduce the mold test times.

2. Advanced equipments:

Ensure the accuracy of the mold. Guarantee elaborate processing to achieve one-time machining in place.

3. Numerous equipments:

100+ equipments in the factory to ensure the processing schedule. Processed and tested directly in our own factory.

4. Quick reply:

Consultation service feedback within 24 hours.

5. Shift system:

3x8 turns working in the factory to ensure the processing progress, shorten mold time and make the mold delivered quickly.

6. Open management philosophy:

With innovative thinking, using new technology and new materials applied to the mold, so that our mold technology takes place in the front ranks of the world.

7. Perfect service:

Regard each set of mold as a boutique. Introduce advanced quality inspection, from purchase to delivery, we pay much attention to every detail in the process.

·

Our Advantages

Injection Mold Design Capacity

Our excellent mold design rely on our professional engineer team and powerful design tools.

1.Professional Engineer Team

We have 50+ engineers in all. They are engaged in CAE simulation and mold flow analysis, experienced in product design, process design and mold structure design as well. Any problem in your mold will be solved in time.

2.Powerful Design Tools

·World-class CAD/CAM/CAE resources

·CATIA,UG,auto form and Auto CAD for mold design and CAE analysis.

·2D/3D design and intelligent NC programming

3.Characteristic Finished Molds

·Hot system injection mold

·Gas-assisted injection mold

·2K/3K mold

Injection Mold Manufacturing Capacity

1. 40+ sets of molds per month

2. Over 2m size for big tool

3. 125T-2500T injection tool machines more than 28 sets

4. 250T for 2K molds, 750T for 3K molds

5. Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets.

6. Fully equipped with grinder machine, milling machine, drilling machine, NC machining, wire cutting machine, etc.

7. We can guarantee the quality and lead time.

| Main Machining Equipments | ||||

| Name | Model | Main Parameter(Stroke:XYZ) (mm) | Brand&Made In | Qty. |

| Five-axis CNC Milling, High Speed | Compact B-2522 | Stroke( X/Y/Z):2000/2500/1200mm; Rotating Speed:24000rpm;Dynamic Accuracy:0.005mm ; | KEN,Taiwan | 1 |

| Five-sided CNC Milling | H-2622 | Stroke( X/Y/Z):2600x2300x1100 ; Accuracy:0.02mm | KAFO,Taiwan | 1 |

| CNC Milling, High Speed | H16M | Stroke( X/Y/Z):1600x1300x700mm; Work table size:1900x1300mm; Accuracy:0.01mm | TAKUMI,Taiwan | 1 |

| CNC Milling, High Speed | F8 | Stroke( X/Y/Z): 1300x800x650mm Work table size:1550x800mm; Positioning Accuracy:0.0015mm | MAKINO,Japan | 1 |

| CNC Milling, High Speed | F5 | Stroke( X/Y/Z): 900X500X350; Work table size:1000*500;Accuracy:0.005mm | MAKINO,Japan | 1 |

| CNC Milling, High Speed | MAKINO V33i | Stroke( X/Y/Z):650*450*350; Rotating speed:20000rev/min; Accuracy:0.002mm | MAKINO,Japan | 1 |

| CNC Milling, High Speed | FANUC A-D14MiB | Stroke( X/Y/Z):500x400x330; Spindle rotate speed:24000rev/min; Work table size:650x400; Accuracy:0.003mm | FANUC,Japan | 2 |

| 3+2 Axis Deep Hole Drill | DHD-2520 | Work table size:2500x2000mm; Accuracy:0.02mm | TEMY,China | 1 |

| Precision EDM (Mirror ) | MAKINO EDGE3i | Stroke( X/Y/Z): 330x250x250mm; Accuracy:0.005/0.003mm; | MAKINO,Japan | 1 |

| Precision EDM | AL60GS | Stroke( X/Y/Z):600x420x370mm; Accuracy: 0.01mm | Sodick,Japan | 1 |

| Precision Wire-Cut | VL600Qs | Stroke( X/Y/Z):600x400x270 mm; | Sodick,Japan | 1 |

| Precision Wire-Cut | AQ360LXs | Stroke( X/Y/Z):360x250x250 mm; | Sodick,Japan | 1 |

| Precision Wire-Cut | V650G | Stroke( X/Y/Z):650x400x350 mm; | EXCETEK,Taiwan | 1 |

| Precision grinding machine | KGS-84AHD | Worktable size: 800x400mm; Max left&right movement:920mm Max moving dimension(front to back):450mm; | KENT,Taiwan | 1 |

Injection Mold Assembly Capacity

We have our own assembly factory.At th same time,the factory is equipped with advanced spotting machines ,the hightest applying pressure is up to 500T. Besides, we have a series of cranes to move the mold more efficiently, the highest holding pressure is up to 30T.What we can benefit from these assembly equipment is as follows:

·Lowering mold cost with a die spotting press

·Reducing the time-cost

·Improving the success rate of mold sampling

·Ensuring the safety and accuracy

Injection Mold Testing Capacity

| Item | Plastic Injection Machine (Tonnage) | Qty. | Remark |

| 1 | 2500 | 1 | |

| 2 | 1800 | 1 | |

| 3 | 1300 | 1 | With EOAT |

| 4 | 700 | 1 | With EOAT |

| 5 | 750 | 1 | 2K/3K |

| 6 | 450 | 1 | |

| 7 | 380 | 1 | |

| 8 | 160 | 1 | |

| TOTAL | 8 |

Injection Mold Measurement Capacity

| Name | Brand/Made In | X | Y | Z | Qty. |

| CMM | Hexagon, Swiss | 1200 | 1500 | 1000 | 1 |

| CMM | AEH | 2000 | 3000 | 1500 | 1 |

| Vision Projector Measurement Machine | China | 300 | 250 | 200 | 2 |

| Alloy Analyzer | LANScientific,China | 2 | |||

| Portable blue ray scanner | China | 1502 | 1002 | 802 | 1 |

| HSCNA-771 |

Packaging & Shipping

Preparation before packaging

Painting is one of the necessary steps before we pack the mold, and we love the mold we produce as if it were our own child.

1.Benefits of painting

1) Form a protective layer with high strength, high hardness and high wear resistance, protect the surface of the mold from corrosion and wear.

2) Make the mold meet the aesthetic standard

3) Make you to identify the set of mold faster when using

2. Painting color: Choose the colors according to your requirements, such as black, green, yellow, blue etc.

3. Protect hot runner connector: Avoid collision and extrusion during transportation and using.

For trial samples delivery:

Express---DHL, FedEX,UPS, TNT, and so on

For die delivery:

1. Domestic--- by road, by air, or others

2. Overseas---by air, by sea

3. By air around 2-5 days. By sea around 15-40 days.

Usually we use wooden cases or plywood cases for the packaging. With rich experience in exporting, we can choose reasonable logistics for you to reduce the shipping risk and the cost of transportation. Of course you can appoint the logistics according to your requirement. We can try our best to satisfy you.

Our Customers

Our customers are from both home and abroad, including KIA, HYUNDAI, TOYOTA, SUZUKI, FAW-GM, and so on. Molds are exported to Japan, Korea, US,New Zealand, Germany, France, Italy, Mexico, Chile, Brazil, Peru, Argentina, etc. more than 30 countries.

Making friends with every customer, providing excellent dies&molds, and creating more value for our buyers, these are our beliefs forever. We welcome you to explore the possibilities.

FAQ

Q1: Are you a trading company or manufacturer ?A: We are factory and located in Qingdao City, Shandong Provice, China.

Q2: What information is required for a quote?

A. Please provide us with product 2D or 3D drawing. If you don't have drawings on hand, samples are also available for checking cost.

Q3: Can I have my own design?

A: Yes, we are very capable to do customized design and make for you. Please share with your ideas, we will discuss your needs, purpose and objective thoroughly and work together with you for the whole project.

Q4: Do you inspect the finished products?

A: Yes, each step of production and finished products will be came out inspection.

Q5: How long is your delivery time?

A: The lead time of T0 sample depends on the mould structure, and generally it takes 40-50 days from receipt of final drawings, deposit and mold design approval. Mass production delivery time depends on the order quantity.

Contact us

Make friends with every customer, provide them with quality products, and create more value for our customers, which is our forever concept.More accurate quotation, please send us 2D/3D drawings of your products to us.

>> SHENGKE Feminine Dazzling Wrist Watches Classic Three Stitches Quartz Watch For Girlfriend Bracelet Watch Reloj Para Mujer

>> Indoor Lighting LED Flat Panel Lamp 2X2 Surface Mounted 40W 600X600 Recessed Backlit Ceiling Square LED Panel Light

>> Supply of high hardness stone crusher pebble granite crusher multi cylinder hydraulic spring cone crusher

>> DD50/2 FINCM CNC Hydraulic Deep Hole Drilling Machine

>> Big Size New Season Chinese Fresh Chestnuts

>> 130mm Bright Steel Rod Production Line

>> Eiboard 77/94-Inch UHD Smart Board Writing Remote Office Video Recording Supports Wireless Bluetooth Projection Whiteboard

>> Runner Container Loading Supervison

>> Wholesale Cheap Price Blank Art Painting Canvas Stretched Canvas for Artist Drawing

>> 7inch Color Camera Video Doorphone Security Doorbell Intercom 600tvl with IC Card

>> 30ml 50ml 75ml Plastic Clear Airless Pump Cosmetic Bottle for Cosmetic Packaging Airless Bottle

>> Construction Industry Portable and Easy to Install 75m3/H-90m3/H Mobile Concrete Batching Plant Price

>> T413609 T413878 T416505 T417806 T417829 T418445 T418446 T419381 T419385 injector for Ingersoll Rand excavator

>> Consumer-Electronics Mobile Phone Accessories USB C Phone Charger for iPhone

>> Best Sell 1.56 Bifocal Round Top UV420 Blue-Cut Optical Lens Eyeglasses Lenses

>> Taijia rebar locator price JY-8SK concrete reinforcement detector rebar scanner

>> 50KG Block Bottom PP Woven Cement bag, Valve Bag, white cement bag.

>> China Manufacturer OEM Rigging Hardware Grade 80 G100 Alloy Steel 1 2 3 4 Double Three Four Leg Multi-Leg 5/16 Inch Crane Lifting Chain Sling with Grab Hook

>> Wholesale NEW SEAGUAR 60m Fluorocarbon Fishing Line Transparent Carbon Fiber high strength line

>> Prima 125t3200mm CNC Press Brake Bending Machine Esavis-S630 System 6+1 Aixs with High Quality

>> OGM series Types Of Flowmeters Oval Gear Digital Meter Gear Flowmeters Meter Gear

>> mindray dp10 portable ultrasound scanner with 12 inch LED screen

>> Jackwin Portable Expandable a-Gate Plastic Barricade Extensible Barrier Foldable Safety Fence

>> Durable Good Quality Livestock Machinery Poultry Farming Broiler Equipment Chicken Farm Feeding Line Drinking Line Nipple Drinker Pan Broiler Feeding System

>> High Compression 60L Vertical Sand Mill Grinding Machine for Laboratory Projects

>> 2-3t/H Small Feed Mill Equipment Used for Poultry Farm

>> Factory Directly Foldable Bluetooth Keyboard for Windows Android Ios Smart Devices with with Touchpad Mini Portable Wireless Bt Keyboard Wholesale

>> Custom Micro Slit for Optics

>> HC-B105 Hot Sell Cheap Portable PT INR Machine Coagulation Analyser INR Diagnostics Handheld Testing Equipment

>> Good Price LPG Gas Cylinder for Laboratory Petroleum Test Instruments